Shell and tube vertical type anti-scaling falling film absorbing device

A falling film absorption and anti-fouling technology, applied in the direction of absorbent/adsorbent, climate change adaptation, energy-saving heating/cooling, etc., can solve the problem of affecting liquid film distribution, absorption effect, cooling water heat transfer effect, and reducing liquid film Effective absorption area, uneven distribution of liquid film, etc., to achieve the effect of enhancing liquid film disturbance, facilitating flushing, and improving mass transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

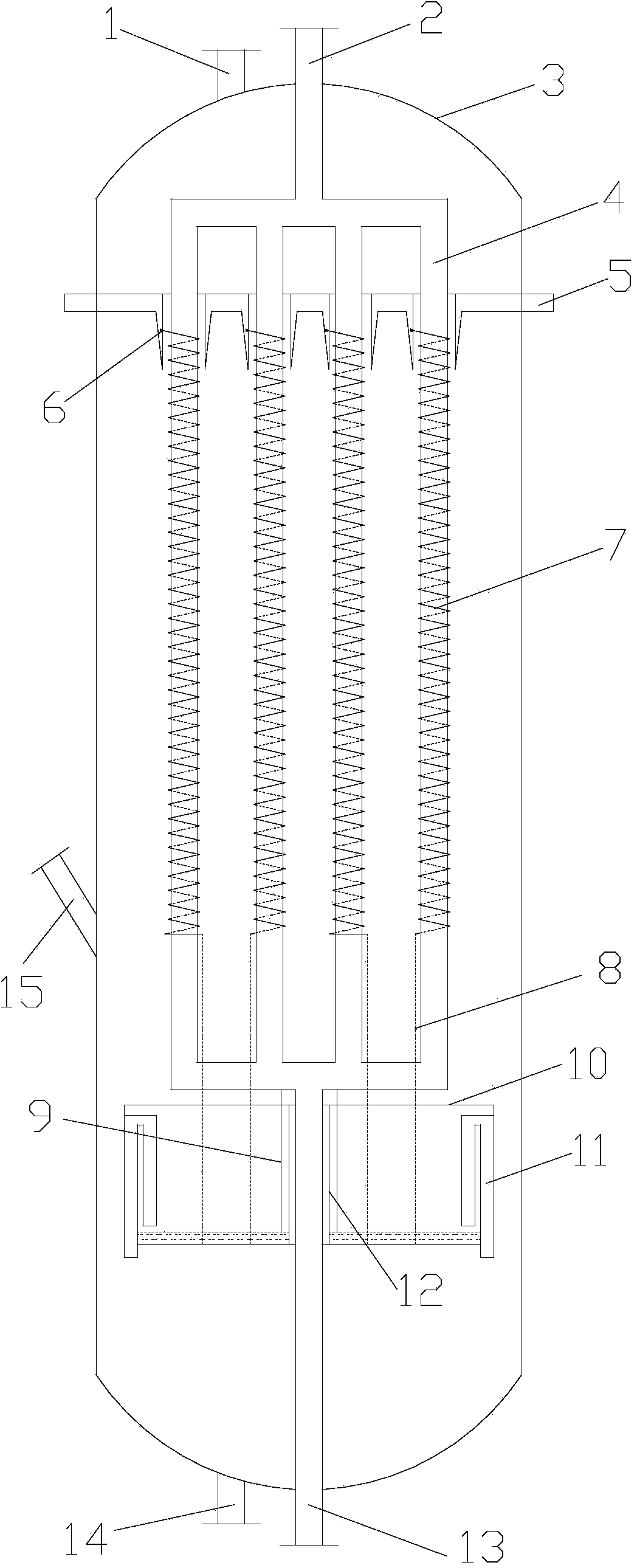

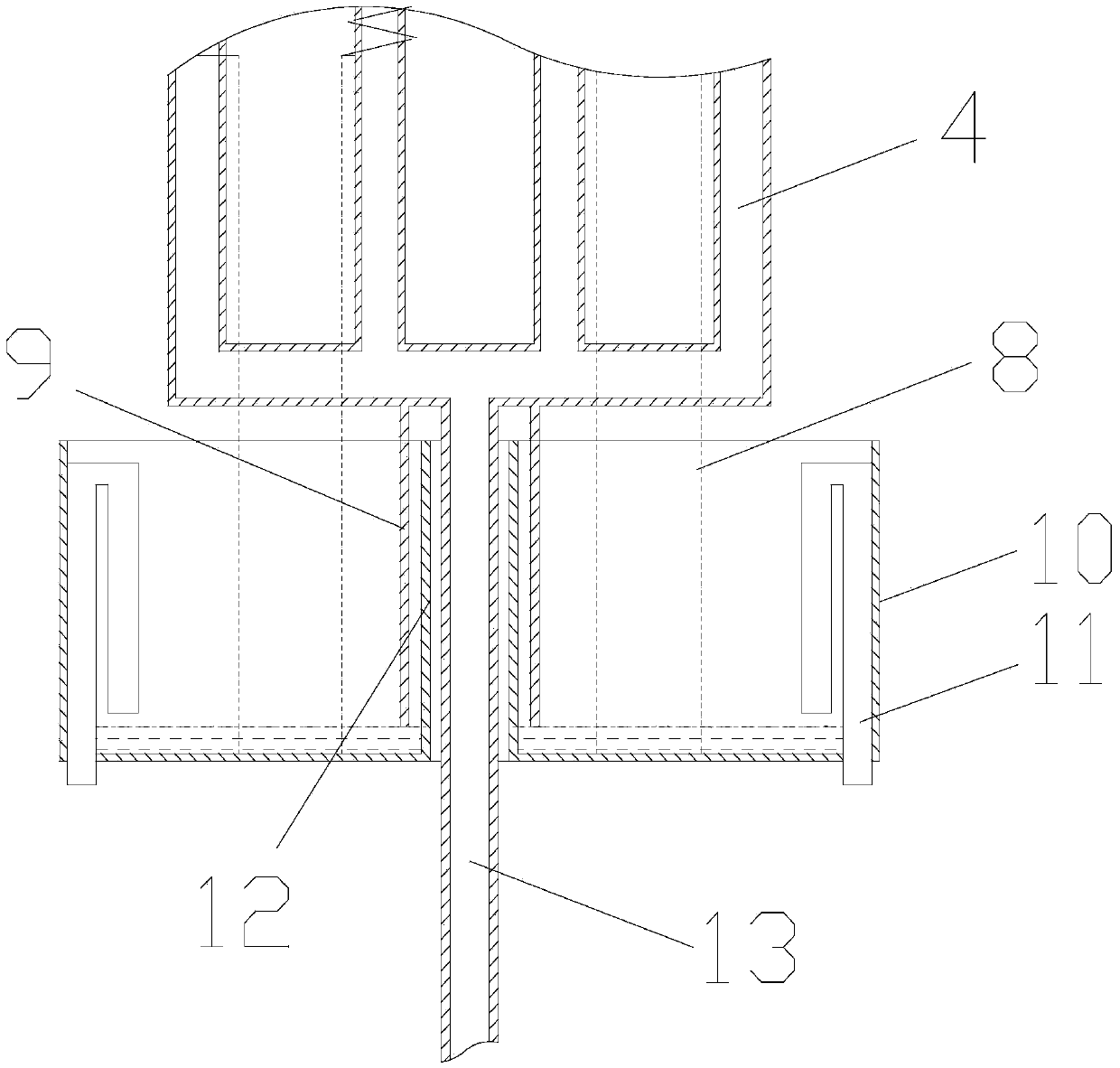

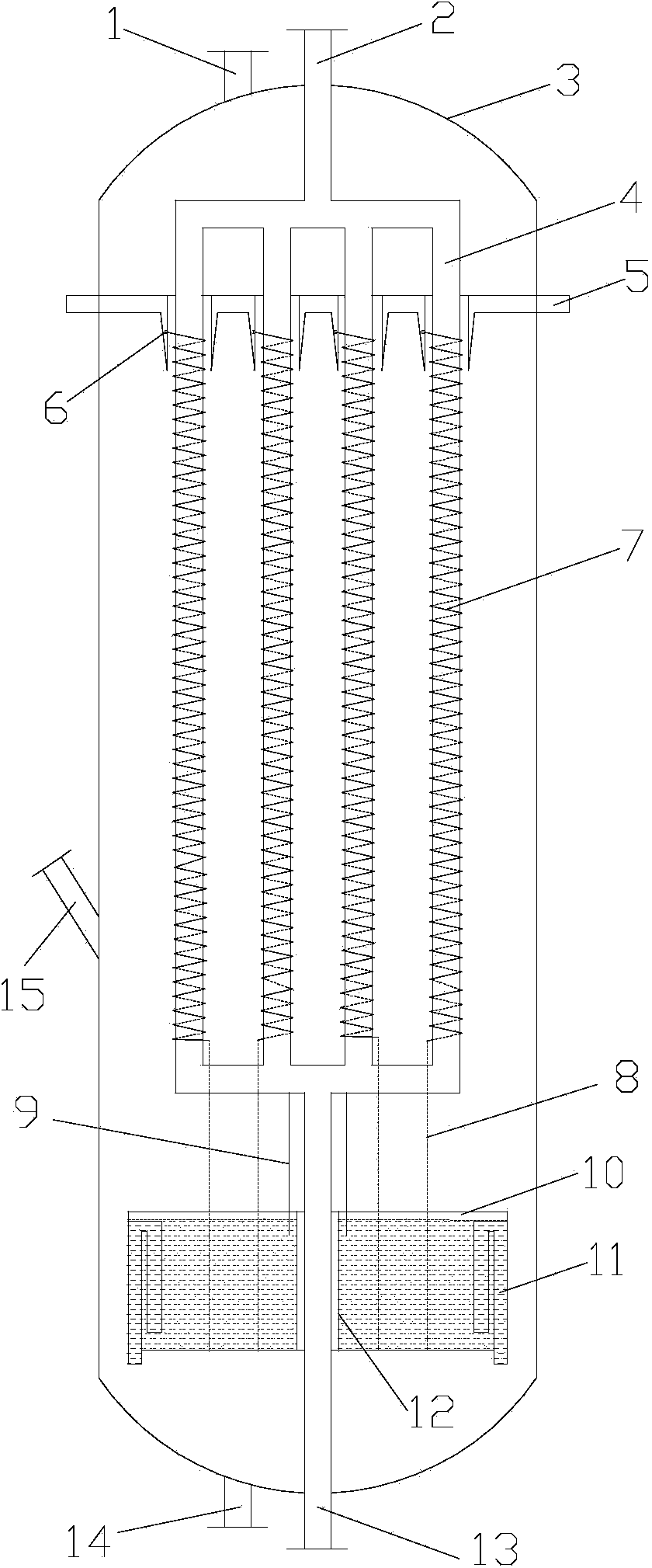

[0027] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0028] Such as Figure 1 to Figure 6 As shown, a tube shell vertical anti-scaling falling film absorption device of the present invention includes a housing 3, and a falling film tube 4 located in the housing 3, a liquid distribution pan 5, an elastic deflector 6, a spring 7 and a liquid contact Disk 10. The top of the housing 3 is provided with a dilute solution inlet 1 and a cooling water outlet, the bottom of the housing 3 is provided with a cooling water inlet and a concentrated solution outlet 14 , and the middle wall of the housing 3 is provided with an absorption gas inlet 15 . The cooling water outlet is connected to the top of the falling film tube 4 through the first water pipe 2 , and the bottom end of the falling film tube 4 is connected to the cooling water inlet through the second water pipe 13 . The liquid distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com