Awning and assembly method thereof

An awning and consistent technology, applied in the field of awnings, can solve the problems of small shading area, poor stability, and weak opening strength, etc., and achieve the effect of increasing the shading area, good resistance to external forces, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

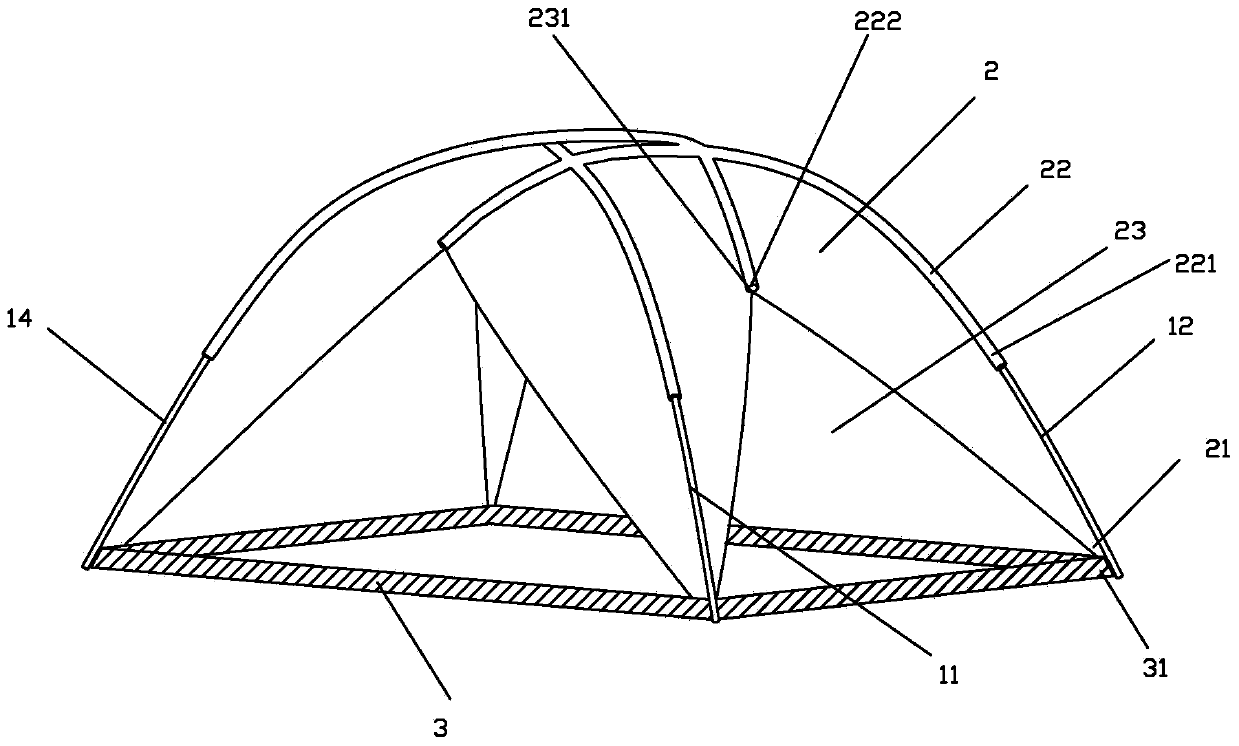

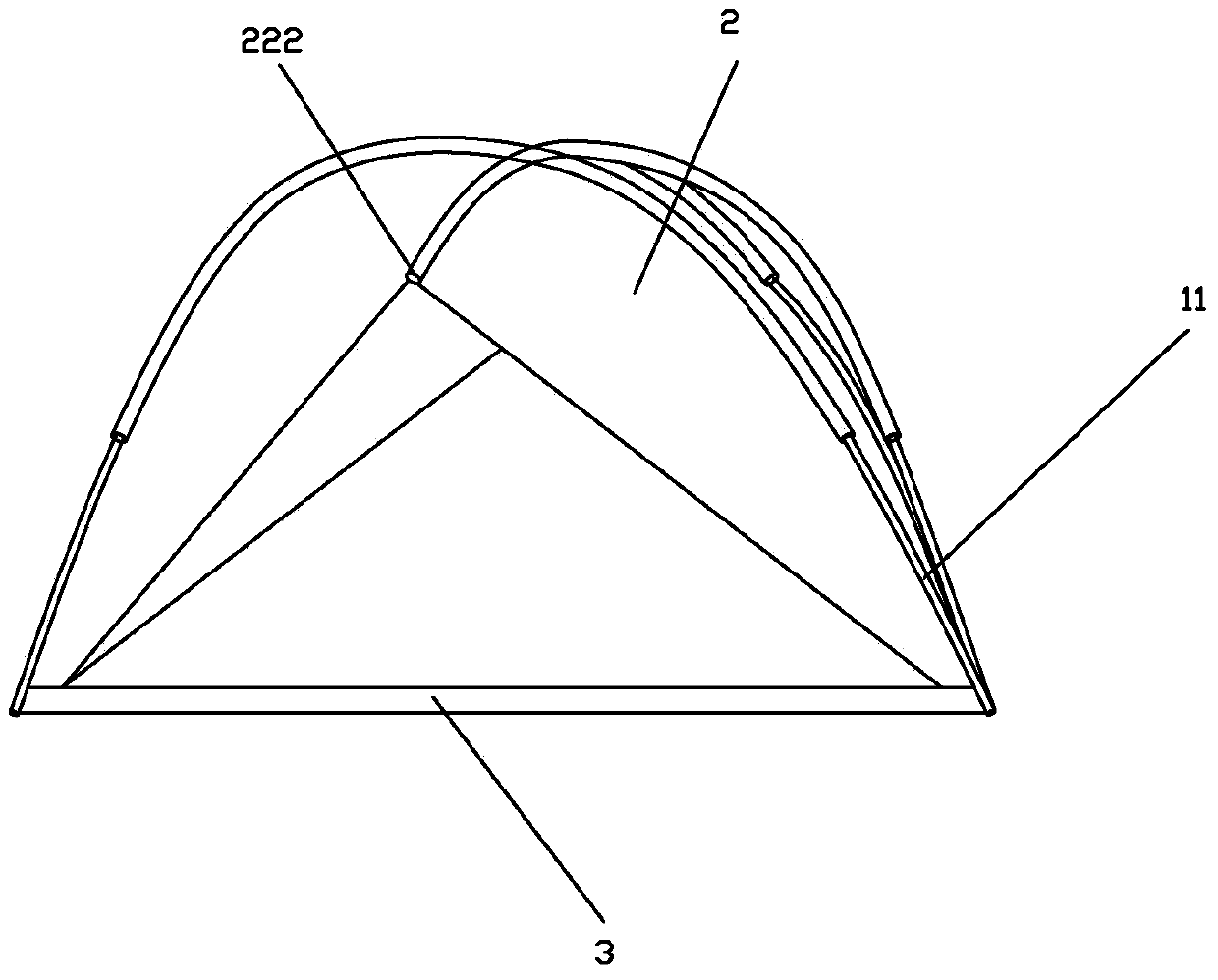

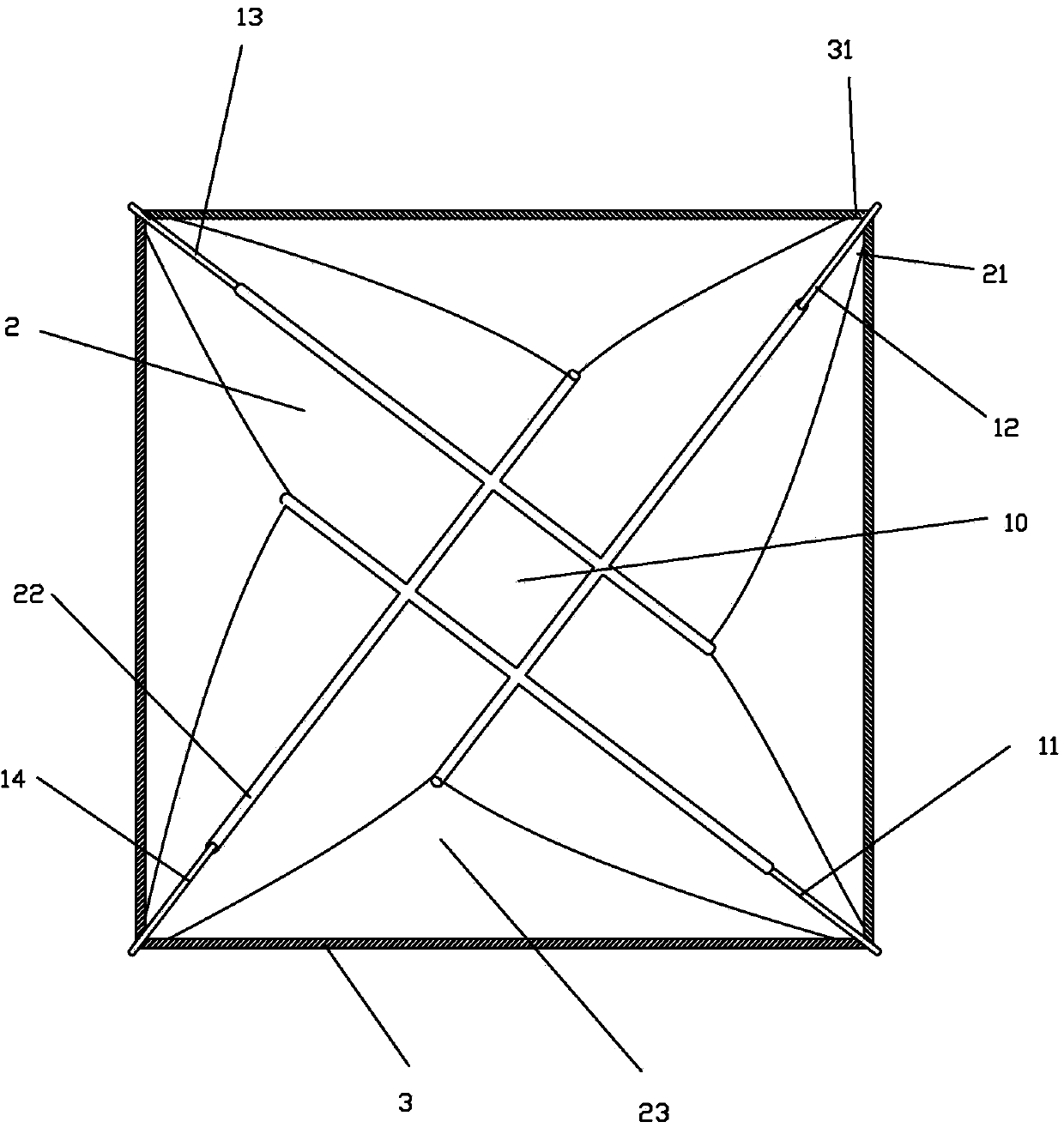

[0033] see Figure 1 to Figure 4 Shown, a kind of awning of the present invention comprises:

[0034] Four flexible rods are respectively flexible rod 11, flexible rod 12, flexible rod 13 and flexible rod 14; each flexible rod can be a complete whole The strip structure can also be formed by a multi-section insert (the prior art has such a structure);

[0035] The upper canopy part 2 has a structure that is stretched into a cover shape, and the projection of the cover shape on the plane has corners 21 that are consistent with the number of flexible rods. Since there are four flexible rods, the upper canopy There are also four corners 21 of the part 2, and the four corners 21 are evenly distributed with respect to the center of the upper canopy part; and

[0036] The bottom tent part 3 has corners 31 consistent with the number of flexible rods. Similarly, since there are four flexible rods, the corners 31 of the bottom tent part 3 are also four, and the four corners The port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com