Punched roof awning frame with eaves

A technology for eaves and awnings, applied in tents/canopies, building types, buildings, etc., can solve the problems of tarpaulins being easily damaged, and the awning area of tarpaulins is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

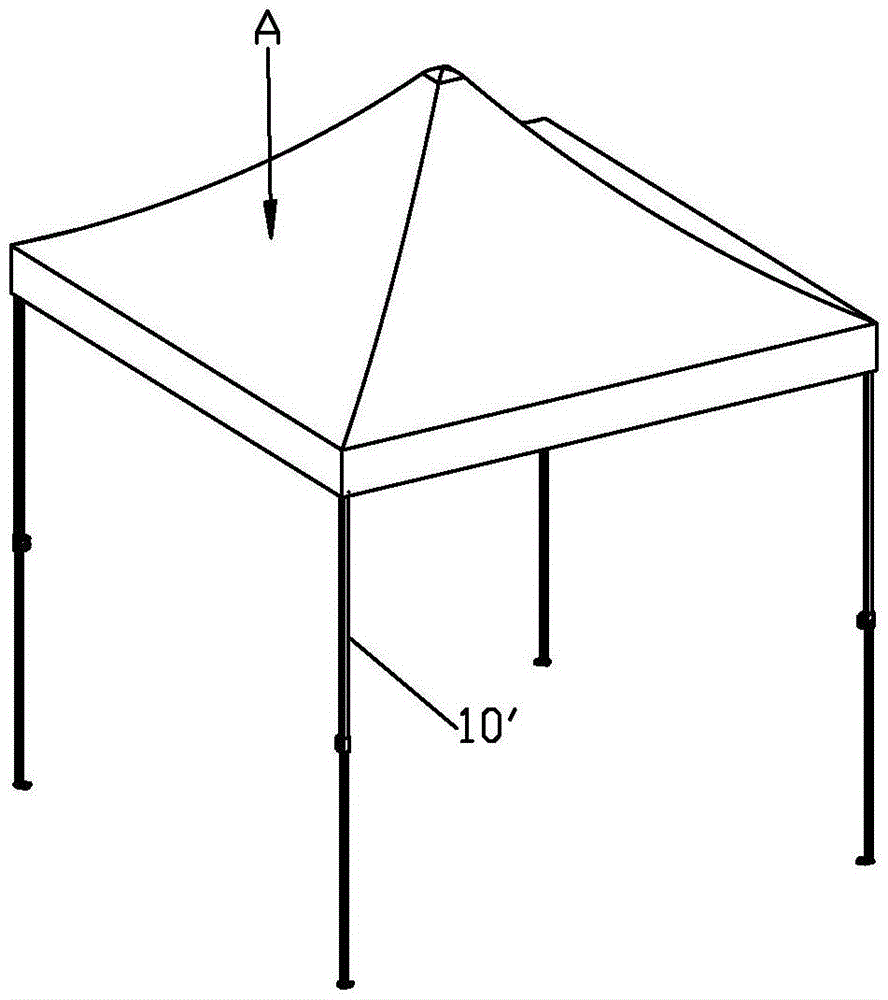

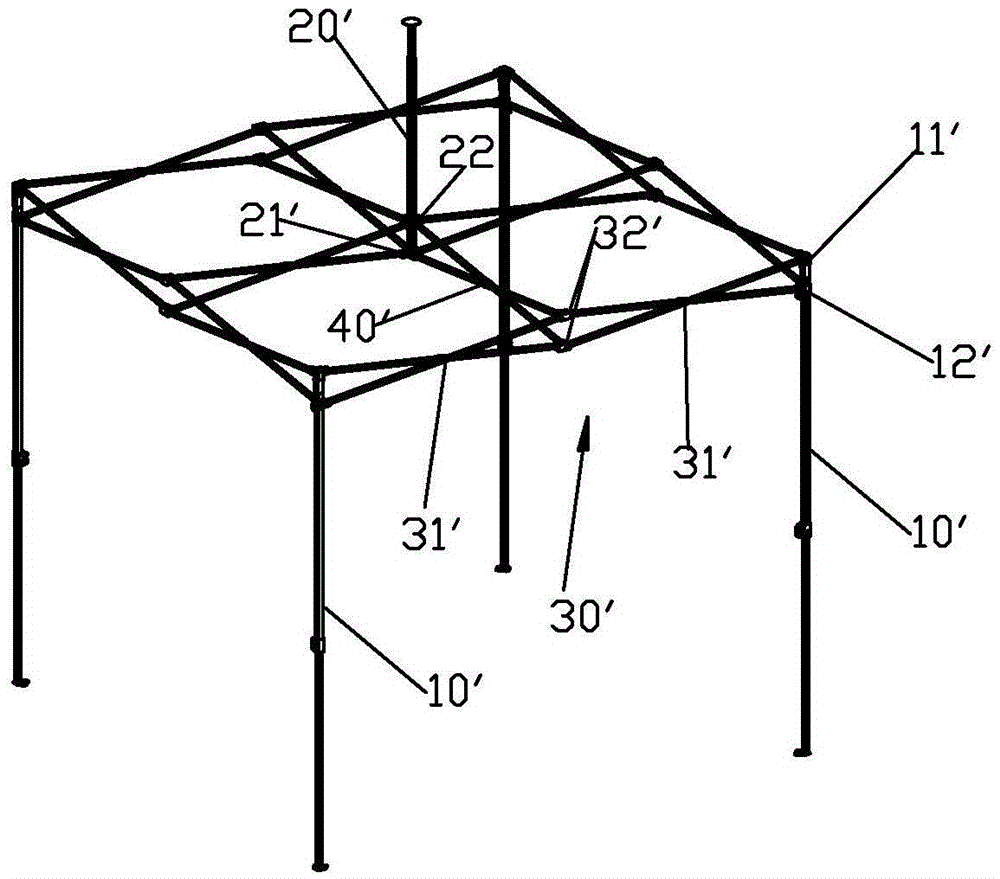

[0040] Please refer to the diagram Figure 4 to Figure 8 , a dome awning with an eave frame, including a dome awning frame and tarpaulin A. The roof awning frame includes at least three uprights 10 and at least one middle pole 20 , the uprights 10 can be telescopic uprights as required, and the at least three uprights 10 are arranged at the corners of the polygon surrounding the middle pole 20 . In this embodiment, four columns are taken as an example, but it is not limited to this, and three columns, six columns, eight columns, etc. can also be used as required. In this embodiment, one middle rod 20 is taken as an example, but it is not limited thereto. According to needs, two middle rods 20 may also be included, as in the second embodiment. Wherein, when there is only one middle pole 20, the second scissor frame is all established between all folding frames and the middle pole, and when there are two or three middle poles 20, then each middle pole and at least two of the co...

Embodiment 2

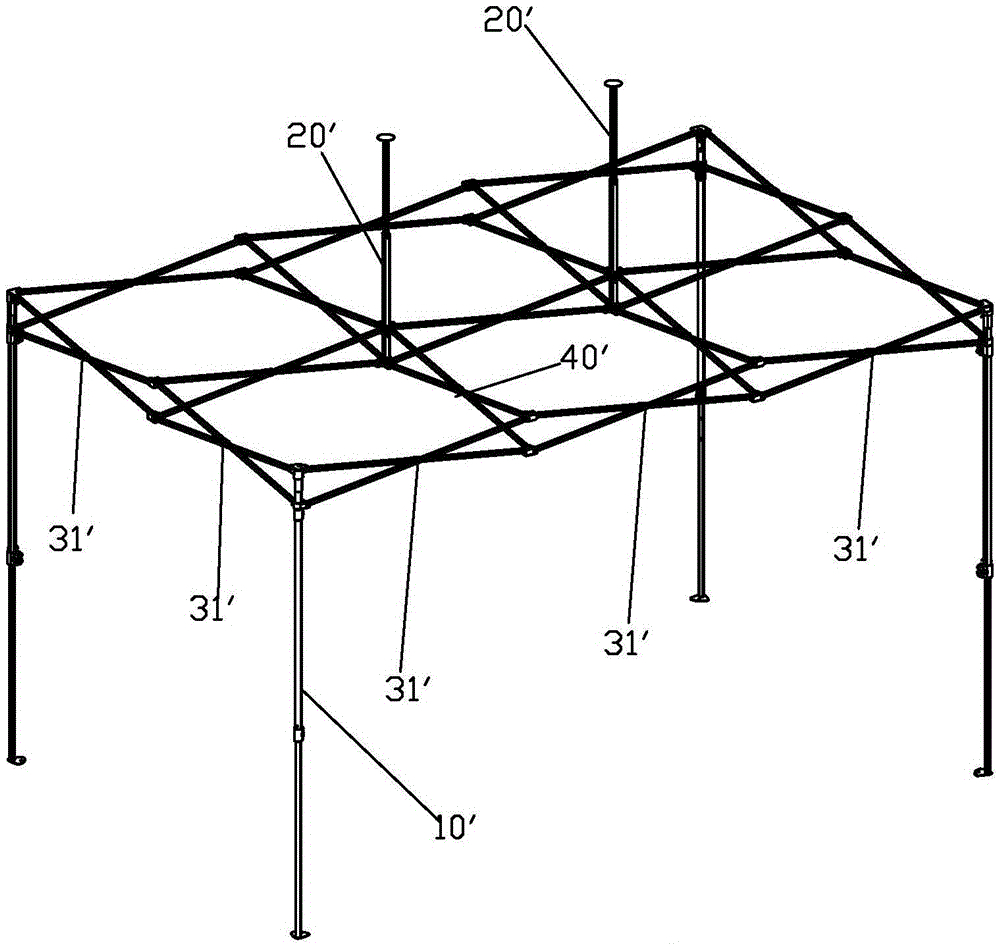

[0051] Please check Figure 9 , it differs from Example 1 in that:

[0052] The roof awning frame includes two middle poles 20; at least one third scissor frame 60 is pivotally connected between the second sliding seat and the base of the two middle poles 20, and the third scissor frame 60 may not be established as required; among the four folding frames The folding frame 30 facing two sides comprises three first scissor frames 31 connected in series, the folding frame 30 has four pivot joints, a second scissor frame is set between the middle bar and the two pivot joints, and the other Another second scissors frame is set between a middle rod and the other two pivots; the other two facing folding frames 30 include two first scissors frames 31 connected in series, the folding frame 30 has two pivots, the A second scissor frame is respectively arranged between the two pivot joints and the two middle rods. Make the entire roof-top awning frame look down and project into a recta...

Embodiment 3

[0054] Please check Figure 10 and Figure 11 , it differs from Embodiment 1 in that: the eave rod 53 is slidably connected to the corner push rod 51 and can extend out of the corner push rod 51 . In a preferred solution, the eave rod 53 is slidably connected in the hollow hole of the corner ram to form a telescopic tube, but it is not limited thereto, as required, it can also be connected to the outer surface of the corner ram to form a sliding connection relationship.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com