Mechanical arm for transferring cans

A technology for manipulators and cans, which is applied in the field of manipulators and canned food transfer manipulators. It can solve the problems of inability to adjust the caliber of cans, affect the appearance of the product, and rigid manipulators. It achieves the effects of fast transfer speed, broad market prospects, and anti-scratch effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Please refer to Figure 4 , The can transfer manipulator 10 is installed on the top of the bracket 20, and a placing rack 30 is installed in the middle of the bracket 20, and the can transfer manipulator 10 is used to transfer the cans on the placing rack 30.

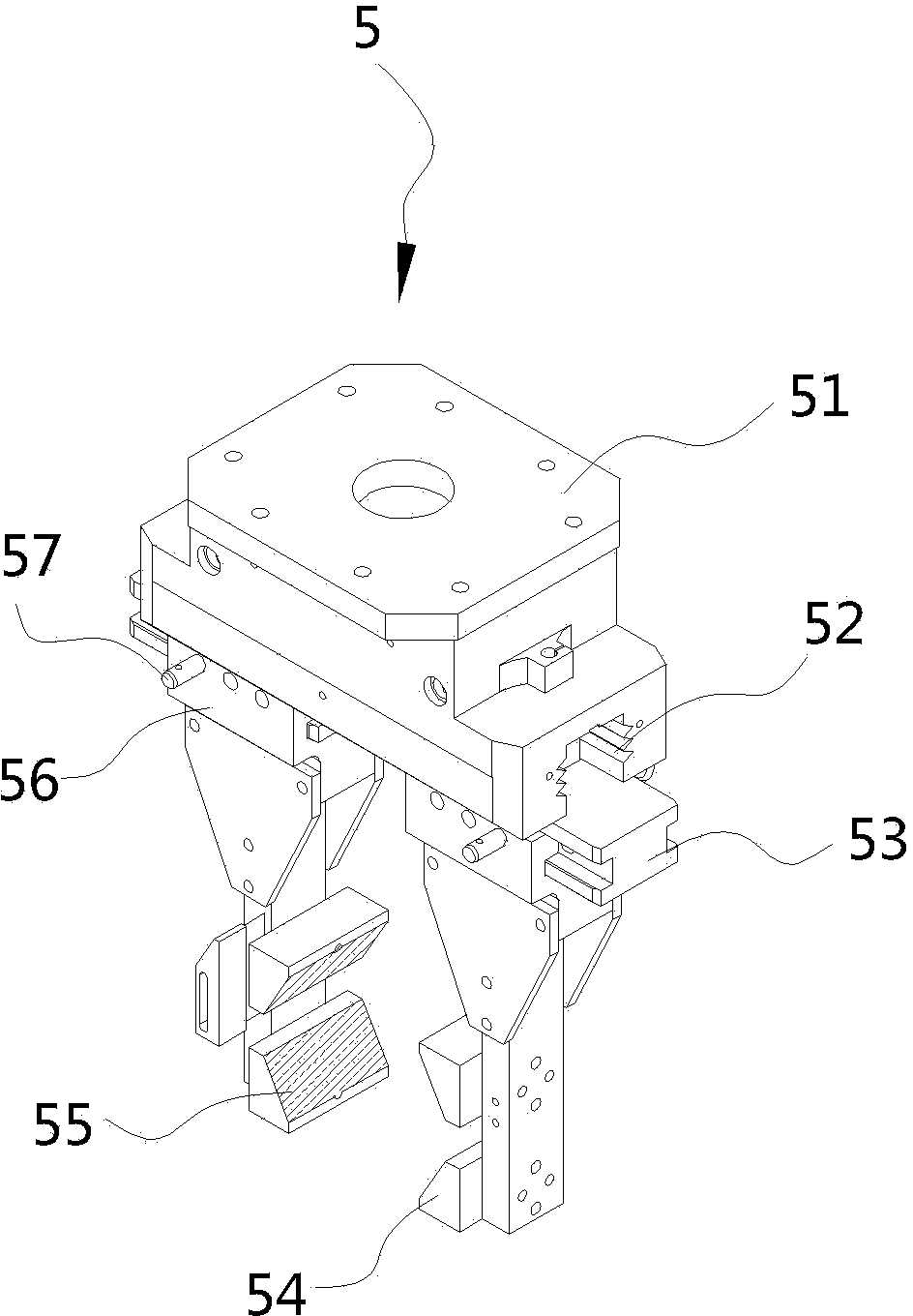

[0020] Please refer to figure 1 , A can transfer manipulator, comprising a rail seat 2, a fixed plate 3 installed on the rail seat 2, characterized in that a cylinder 1 that drives the fixed plate 3 to slide is installed in the middle of the rail seat 2, and the fixed plate 3 A clamping manipulator 5 driven up and down by the cylinder 2 4 is installed on it.

[0021] Please refer to figure 2 , image 3 with Figure 4 , The clamping manipulator 5 includes a connecting block 51. The lower part of the connecting block 51 is provided with a guide groove structure 52. Two sliding blocks 53 are installed on both sides of the guide groove structure 52, and a clamping arm that can slidably adjust the spacing is installed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com