Isothermal forging die for complex aviation thin-walled part

A technique for thin-walled parts and isothermal forging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

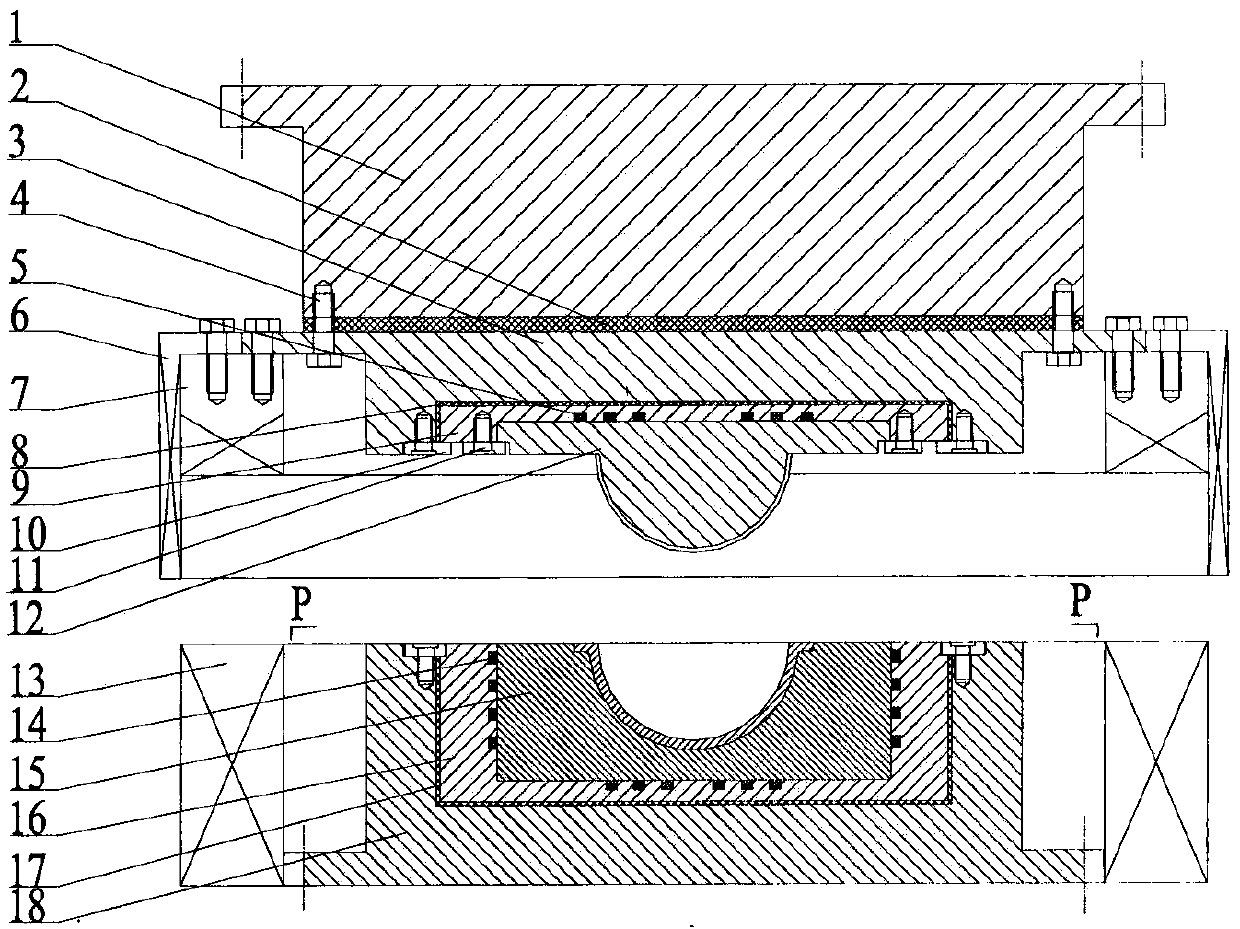

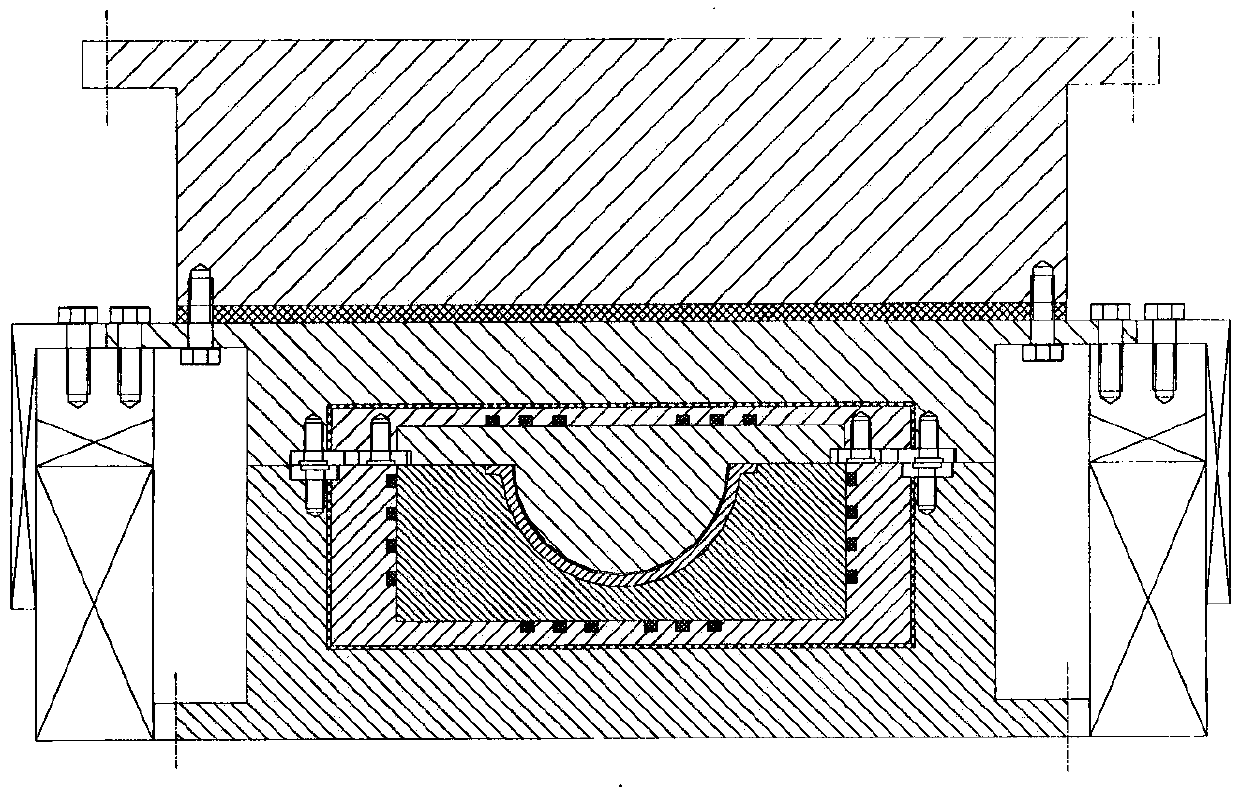

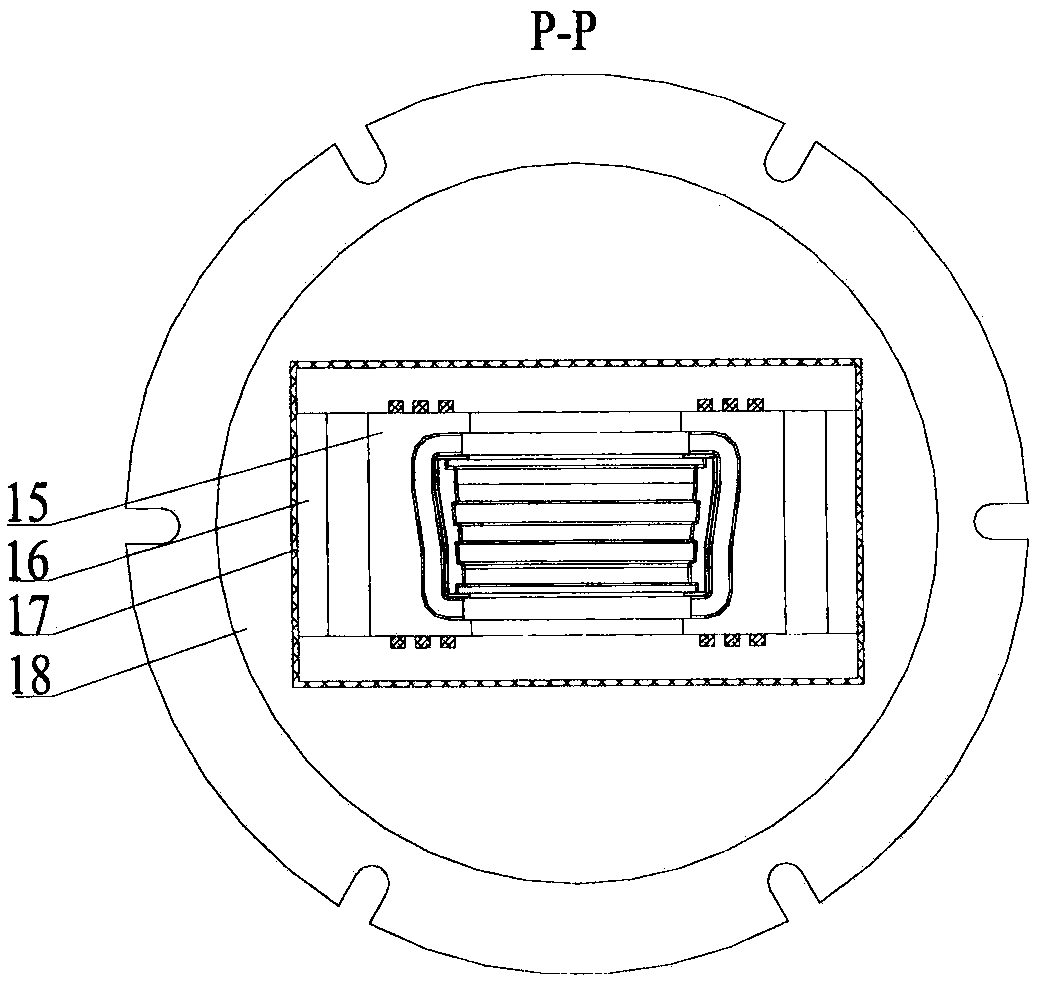

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] Figure 1-4 It is an isothermal forging die device for complex aviation annular thin-walled parts. Such as figure 1 As shown, steps are processed at the edge of the upper die 12, and are connected to the upper die cover 9 through the pressing block 10 and the bolt 11. The pressing block 10 is flush with the steps of the upper die 12; groove, and the distance between the heating grooves is 70mm; the upper die cover 9 is connected with the upper die base 3 through the pressure block 10 and the bolt 11, and the pressure block 10 is flush with the steps of the upper die base 3; the upper die cover 9 and the upper die base 3 Aluminum silicate fiber insulation boards 8 are placed between them to reduce the heat loss of the upper mold cover 9; Move together with the upper mold 12; the L-shaped heat preservation barrel 6 is inverted and fixed on the upper heat preser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com