Milk foaming device capable of automatically producing foamed milk

An automatic generation and foaming device technology, applied in beverage preparation devices, household utensils, applications, etc., can solve problems such as poor taste, short mixing time, and short residence time, and achieve fast deceleration, small centrifugal force, and low density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

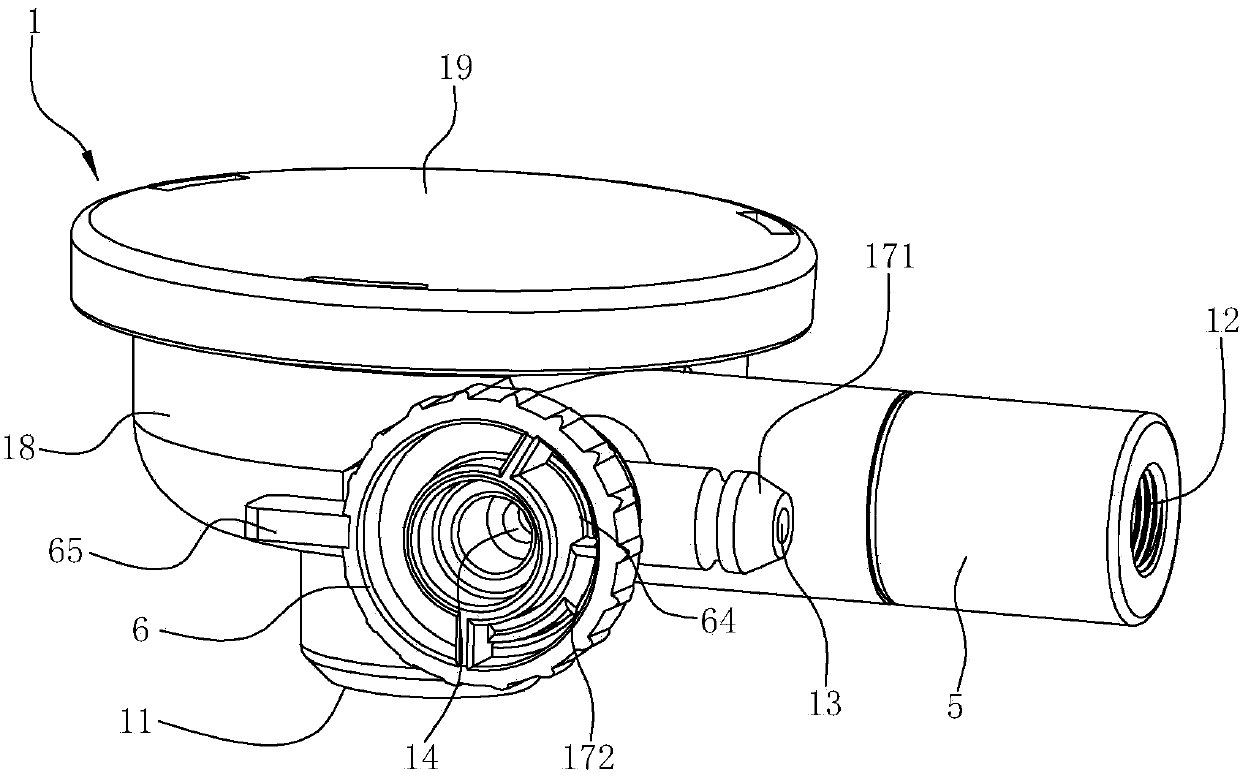

[0031] like Figure 1~4 Shown is the first embodiment of the present invention.

[0032] A milk foaming device for automatically producing frothed milk, comprising a housing 1 with a chamber inside, an outlet 11 is provided at the bottom of the housing 1, a steam supply channel 12 and a milk supply channel 13 are provided at the side of the housing 1 And into the air channel 14.

[0033] The housing 1 is formed by a detachable connection between the base 18 and the upper cover 19. In this embodiment, the base 18 and the upper cover 19 are connected by buckles, and a third sealing ring 4c is provided between the base 18 and the upper cover 19. The outlet 11 is arranged on the bottom surface of the base 18 , and the steam supply channel 12 , the milk supply channel 13 and the air inlet channel 14 are arranged on the side of the base 18 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com