Spiral liquid nitrogen refrigeration equipment for aquatic product

A liquid nitrogen freezing and aquatic product technology, which is applied in the direction of freezing/cooling to preserve meat/fish, etc., can solve the problems of reducing the freezing efficiency of aquatic products and the overall freezing quality, high utilization rate of cooling capacity, high utilization rate of space, etc., to improve Freezing efficiency and overall freezing quality, high cooling capacity utilization, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

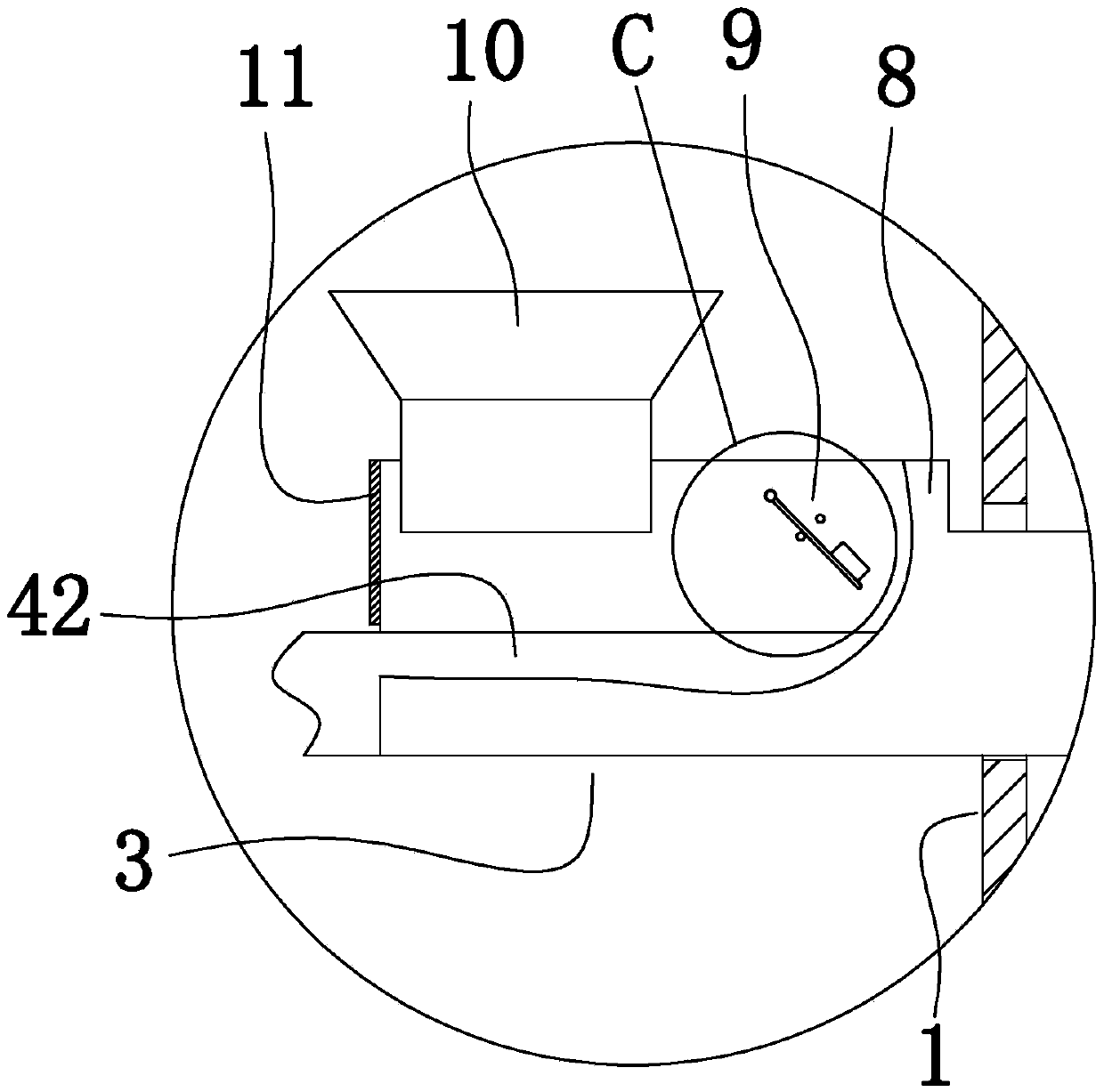

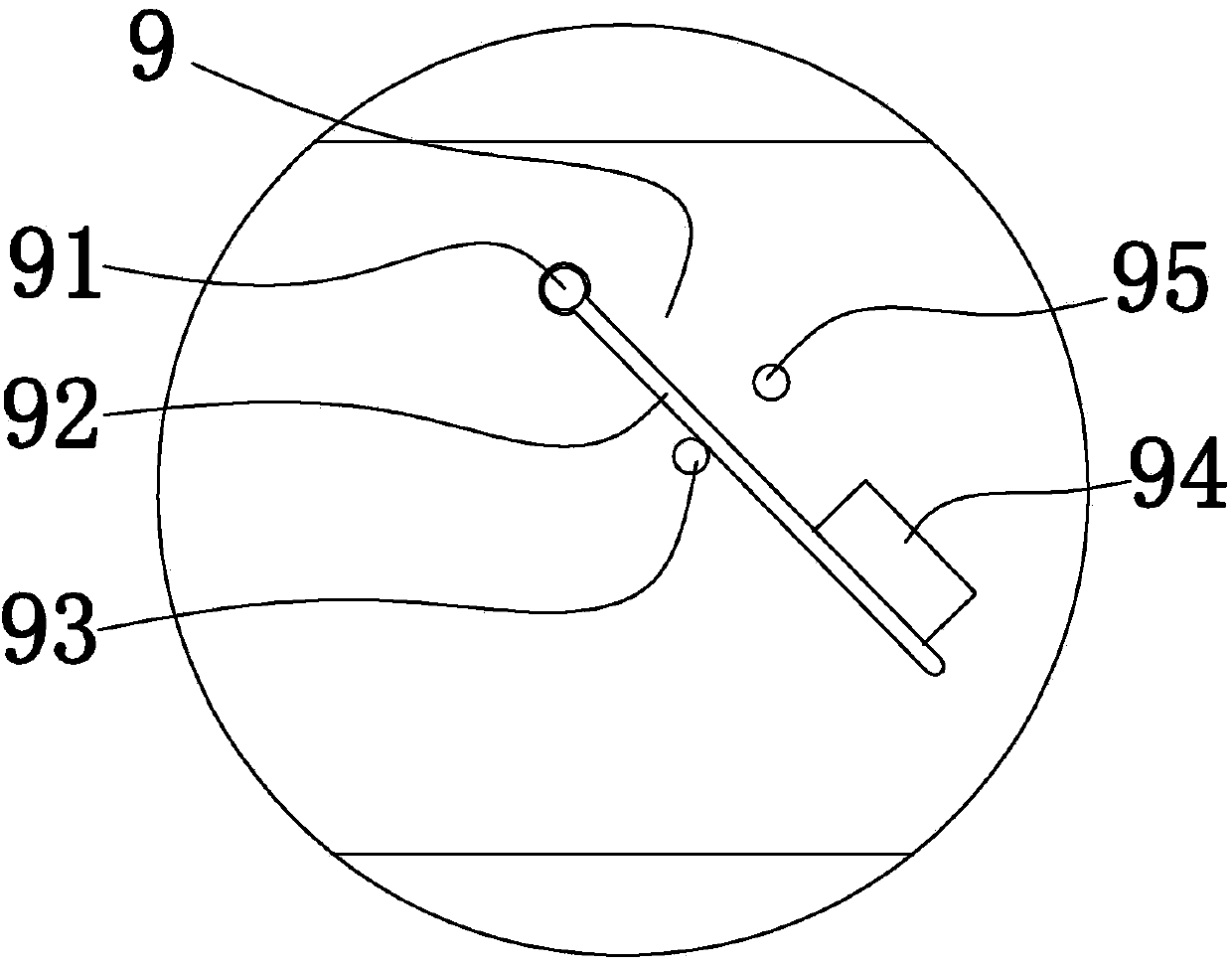

[0018] Such as figure 1 , figure 2 , image 3 As shown, a spiral liquid nitrogen freezing equipment for aquatic products includes a freezing chamber 1, a vertical screw conveyor 4 arranged in the freezing chamber for transferring aquatic products, and a turning device arranged on the vertical screw conveyor for turning aquatic products 5. The screw conveyor is a kind of conveying equipment in the prior art, which is used to convey materials from bottom to top / top to bottom. The vertical screw conveyor includes a support column 41 and a spiral conveyor chain 42 spirally rising along the support column. The top of the spiral conveyor chain extends horizontally to the outside of the freezing chamber and forms a feeding section 3 outside the freezing chamber. The bottom of the spiral conveyor chain extends horizontally to the outside of the fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com