No-tillage aphid-preventing and disease-preventing efficient cultivation method for flue-cured tobacco

A cultivation method and flue-cured tobacco technology are applied in the field of no-tillage, aphid-proof, disease-proof and high-efficiency cultivation of flue-cured tobacco, can solve the problems of increasing the labor cost of flue-cured tobacco planting, many steps in flue-cured tobacco planting, large labor load, etc., and achieve the saving of production labor cost and the maximum land utilization. effect of increasing productivity and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with embodiment:

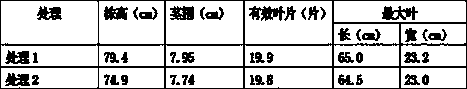

[0013] The planting site is an experimental field in the Huanghuai Tobacco Area, which is divided into two parts, each with an area of 800 square meters. The flue-cured tobacco is selected from the main local varieties, such as Yunyan 85, and the wheat is selected from high-quality strong gluten wheat varieties, such as Waramai 8901.

[0014] Process 1: plant flue-cured tobacco according to the method of the present invention, the steps are as follows

[0015] 1) In October of the first year, wheat was planted in the field according to conventional methods;

[0016] 2) Plant tobacco seedlings between wheat rows in April of the second year, with a plant spacing of 50 cm, a row spacing of 1 meter, and a depth of 5-8 cm in the tobacco planting hole;

[0017] 3) The wheat is harvested in June, and the height of the wheat stubble is 0.2-0.3 meters. 25-30 days after harvesting the whea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com