Hollow ultrasonic motor allowing stator to float

An ultrasonic motor and stator technology, applied in the field of electronics, can solve the problems of limited motor design space, low efficiency, small inner hole of hollow motor, etc., and achieve the effect of stable motor operation, favorable processing and assembly, and high linearity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

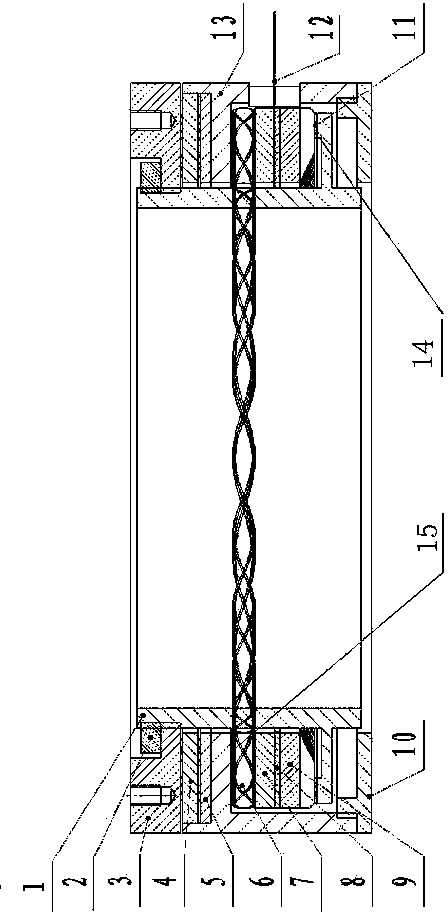

[0034] Such as Figure 1-4 shown.

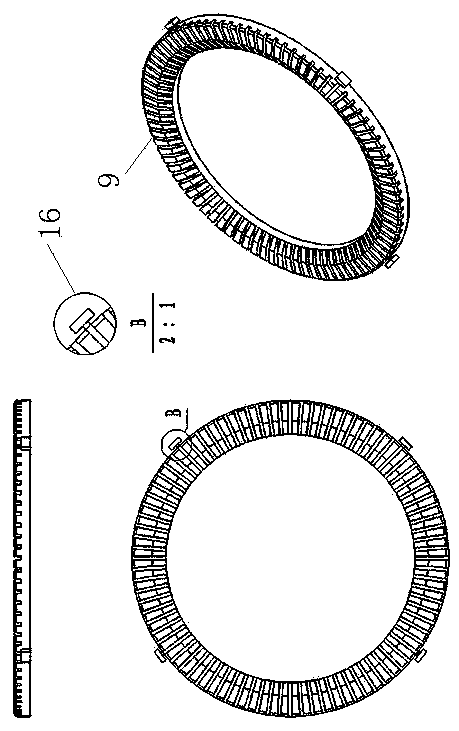

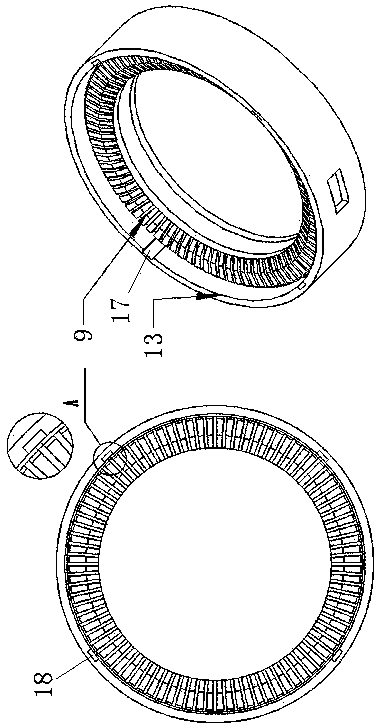

[0035] A hollow ultrasonic motor with a floating stator, which includes a rigid rotor 1, a lock nut 2, a preload nut 3, and a thrust bearing 4 (such as Figure 5 ), wear-resistant sheet 5, wave spring 6, insulating pad 7, piezoelectric ceramic sheet 8, stator 9 (such as figure 2 ), end cover 10, friction plate 11, flexible printed board 12 and base 13, such as figure 1 shown. Both the lock nut 2 and the preload nut 3 are screwed on one end of the rigid rotor 1, one end surface of the lock nut 2 is against the one end surface of the preload nut 3 to prevent its axial movement, and the other end of the preload nut 3 Supported on the thrust bearing 4 so that the preload nut 3 can rotate synchronously with the rigid rotor 1, the thrust bearing 4 is installed on one end of the base 13, and the end cover 10 is install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com