Frame sealing glue solidifying device and mask plate thereof

A technology of curing device and mask plate, which is applied to devices, optics, instruments and other directions for coating liquid on the surface, can solve the problems of increased adsorption load of mask plate, damage to liquid crystal panel, mask plate falling off, etc., and achieves the effective area The effect of reducing, reducing the load, reducing the risk of pressure drop off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

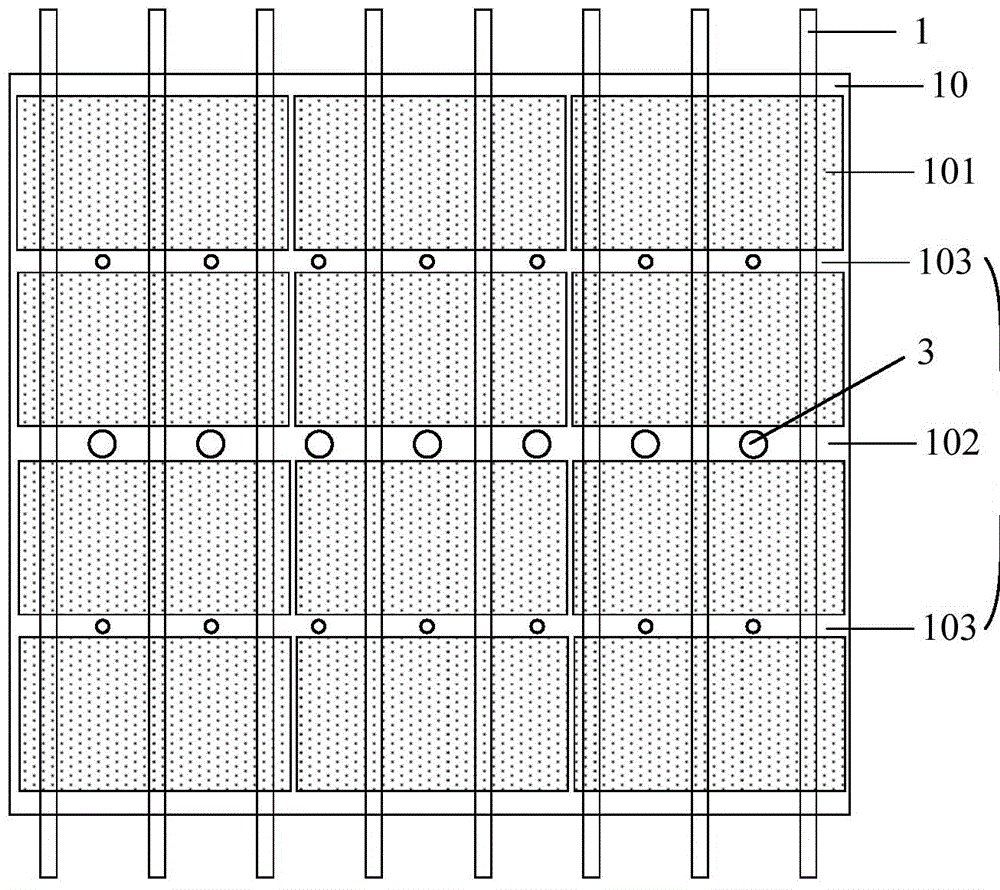

[0030] Such as figure 1 As shown, a mask 10 for curing the frame sealant is provided in this embodiment, which includes a light-transmitting region 100 and a light-shielding region 101, and the light-transmitting region 100 of the mask for curing the frame sealant on the liquid crystal panel It is a plurality of strip-shaped light-transmitting areas that intersect horizontally and vertically (such as figure 1 102, 103 in ), the area defined by the intersection of the strip-shaped light-transmitting areas is the light-shielding area 101, which corresponds to the display area of the liquid crystal panel. For the convenience of description, the extending direction of the length of the liquid crystal panel is defined as the horizontal direction, and the extending direction of the width is defined as the vertical direction.

[0031] At least one through hole 3 is provided in the light-transmitting area 100, mainly serving as an air intake hole. combine figure 2 As shown, afte...

Embodiment 2

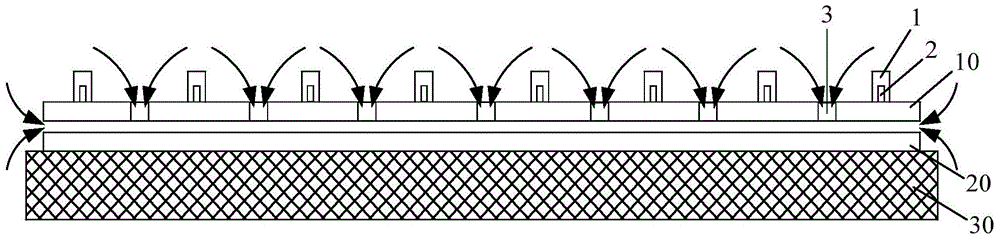

[0039] Such as figure 2 As shown, this embodiment provides a sealing sealant curing device, which includes a mask plate 10 and a vacuum suction device for fixing the mask plate 10, wherein the mask plate 10 adopts the mask plate in the first embodiment , used to reduce the risk of the mask plate 10 coming off due to the pressure difference, and ensure the mass production efficiency of the sealing glue curing device.

[0040] Specifically, the vacuum adsorption device is adsorbed on the upper surface of the mask plate 10 . An object stage 30 is provided below the mask plate 10 for fixing the liquid crystal panel 20 cured by the pre-seal sealant. And a driving device (not shown in the figure) is provided to drive the stage 30 to move, so that the liquid crystal panel 20 fixed thereon is away from the exposure position (the exposure position is about 3mm) or reach the exposure position.

[0041] Wherein, the vacuum adsorption device may be a plurality of transparent rods 1, s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com