Cigarette defect simulator

A technology of simulators and defects, applied in the field of simulators, can solve problems such as mixing, and achieve the effects of improving production efficiency, ensuring verification results, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

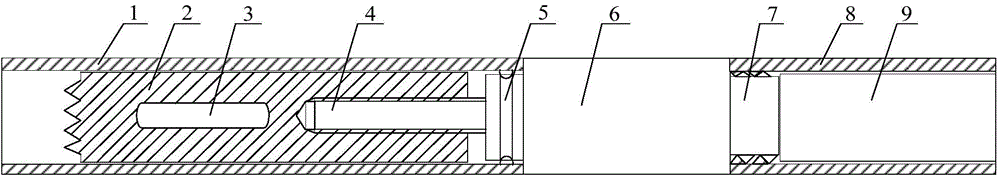

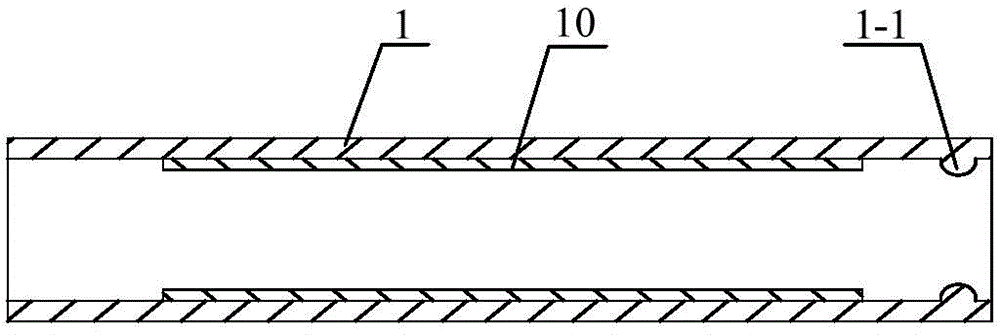

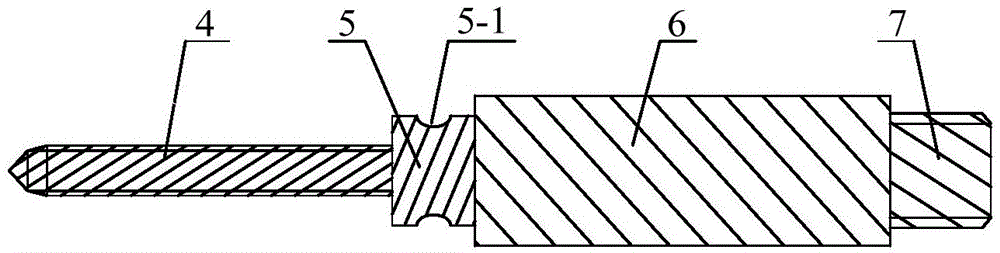

[0032] like Figures 1 to 3 As shown, the cigarette defect simulator of the present invention includes a sleeve, and a simulated inner core is also arranged inside the sleeve. The simulated inner core includes a short simulated inner core 2, and the short simulated inner core 2 is used to simulate a short defect of a cigarette. The front end of the dummy inner core 2 is the reflection end, and the surface of the reflection end of the dummy inner core 2 is set as a concave-convex surface, such as figure 1 As shown, the concave-convex surface of the reflective end can be used to simulate the irregular shape of the cut tobacco end face of a hollow cigarette.

[0033] An electronic transponder 3 is also provided on the dummy inner core 2 . The electronic transponder 3 in this embodiment is built in the dummy dummy core 2 , and the electronic transponder 3 is located at the front end of the dummy dummy core 2 . The electronic transponder is used for the response and signal feedba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com