Determination apparatus and determination method for reinforcing steel bar corrosion rate

A steel bar corrosion and measuring device technology, applied in measuring devices, weather resistance/light resistance/corrosion resistance, material weighing, etc., can solve the problems of cumbersome operation process, low detection efficiency, measurement error, etc., and achieve simple operation and high detection efficiency High, high detection accuracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

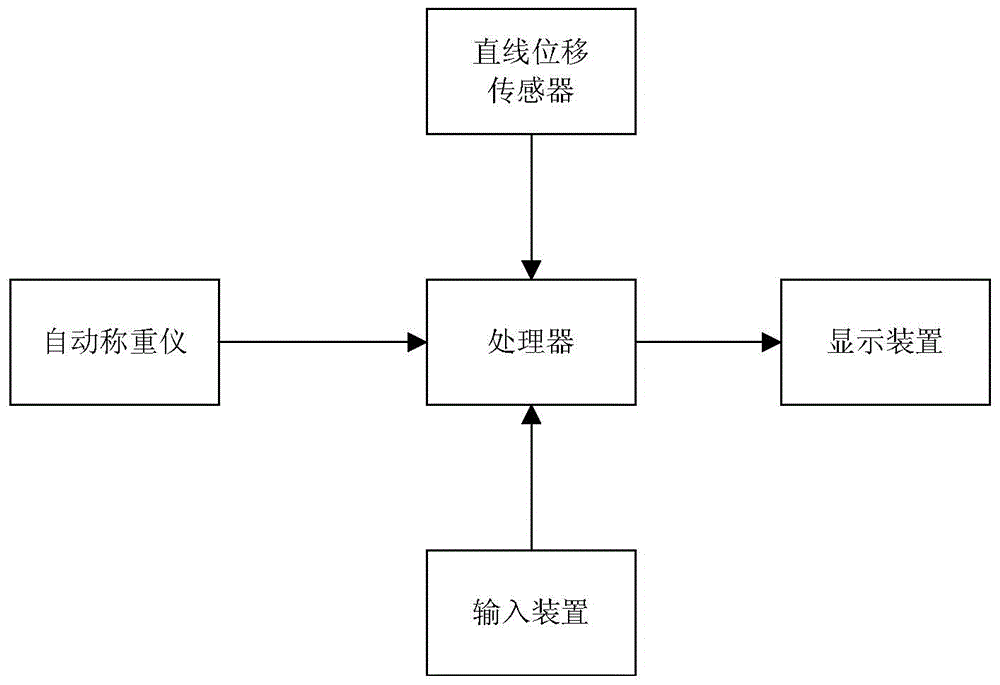

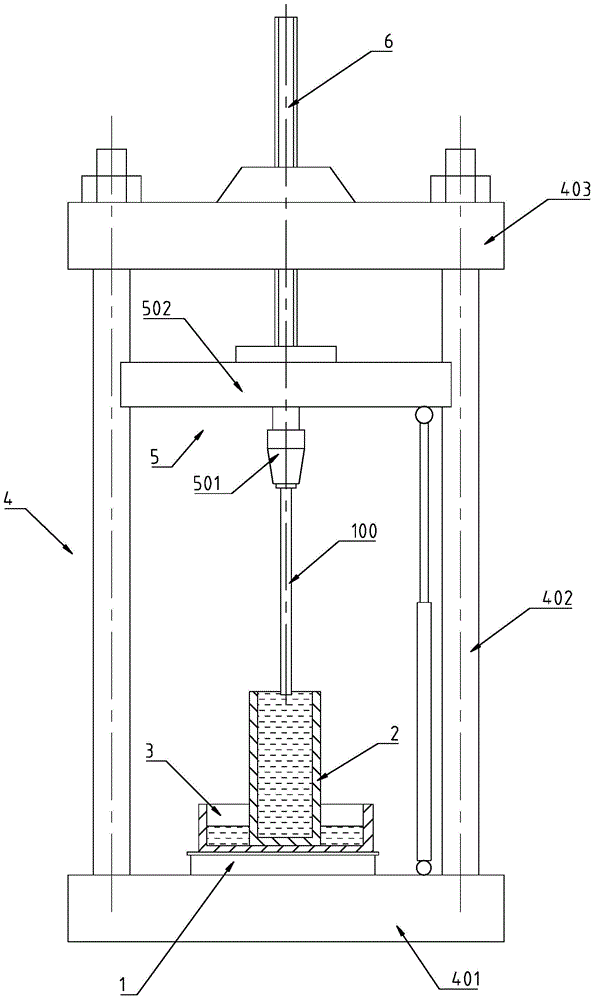

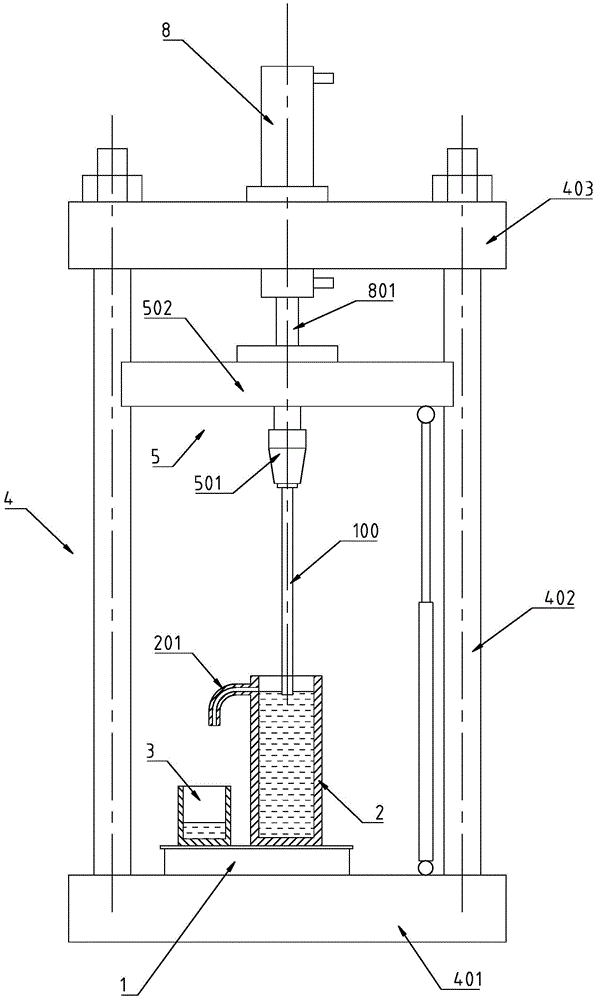

[0029] The structure of the measuring device embodiment 1 of steel bar corrosion rate of the present invention is as figure 1 with figure 2 As shown, it includes a weighing instrument 1, a computer system, a steel bar lifting device, a liquid container 2 and an overflow container 3.

[0030] The structure of the main part of the steel bar lifting device is similar to a common press machine, including a frame 4, a clamp 5, a clamp lifting mechanism and a photoelectric linear displacement sensor 7 that senses the lifting distance of the clamp.

[0031] The fixture 5 includes a steel bar clamp 501 and a guide block 502 , and the steel bar clamp 501 is installed below the guide block 502 .

[0032] The frame 4 includes a workbench 401 , a guide rail 402 and an upper beam 403 . The guide block 502 is slidingly matched with the guide rail 402 and moves linearly along the guide rail 402 .

[0033] The clamp lifting mechanism includes a leading screw nut mechanism 6 and a motor co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com