Straight-through type three-cavity silencer

A muffler and straight-through technology, applied in the direction of mufflers, machines/engines, engine components, etc., can solve the problems of single air flow channel and large noise, and achieve the effect of improving muffler effect, reducing noise and effectively dissipating heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below with reference to the embodiments and accompanying drawings, but the embodiments of the present invention are not limited thereto.

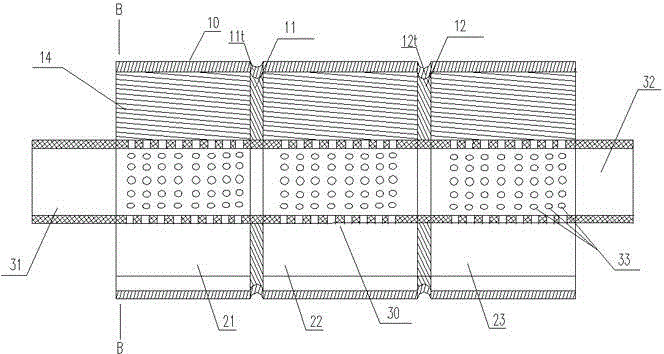

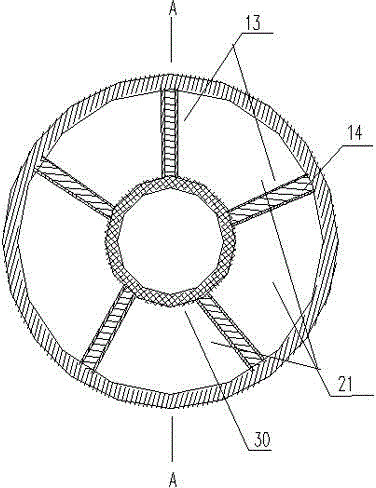

[0015] Embodiment 1 of the present invention is, as figure 1 , figure 2 As shown, it includes a muffler cylinder 10, an airflow duct 30 with an inlet end 31 and an exhaust end 32, the airflow duct spans the muffler cylinder, and also includes a first chamber partition 11, a second chamber The chamber partition 12, the first chamber partition and the second chamber partition divide the muffler cylinder into a first chamber group 21, a second chamber group 22, and a third chamber group 23. A plurality of interlayer partitions 13 are provided in the three chamber groups, and the interlayer partitions are composed of two single-layer metal partitions separating a gap layer, the gap layer is a resistive sound-absorbing layer 14, and the The interlayer partition connects the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com