Cold-bridge-free spanner tightness adjusting lock

A kind of elastic adjustment, cold bridge technology, applied in building locks, handle connection, door/window accessories, etc., can solve the problems of complex lock body structure, poor sealing performance, etc., to achieve good effect, easy operation and use, long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

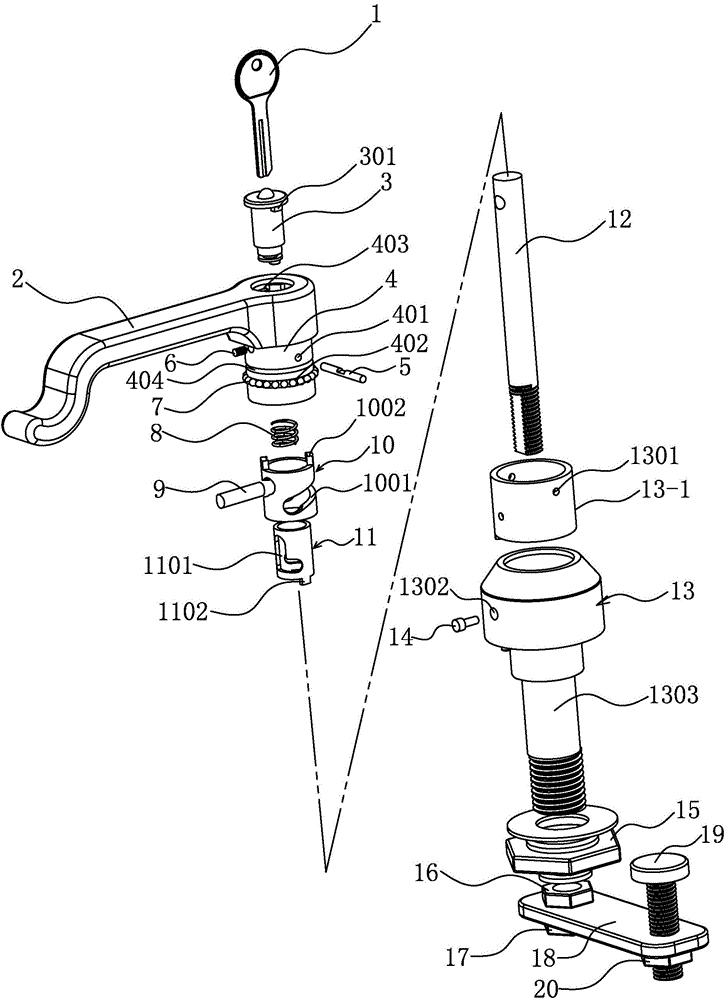

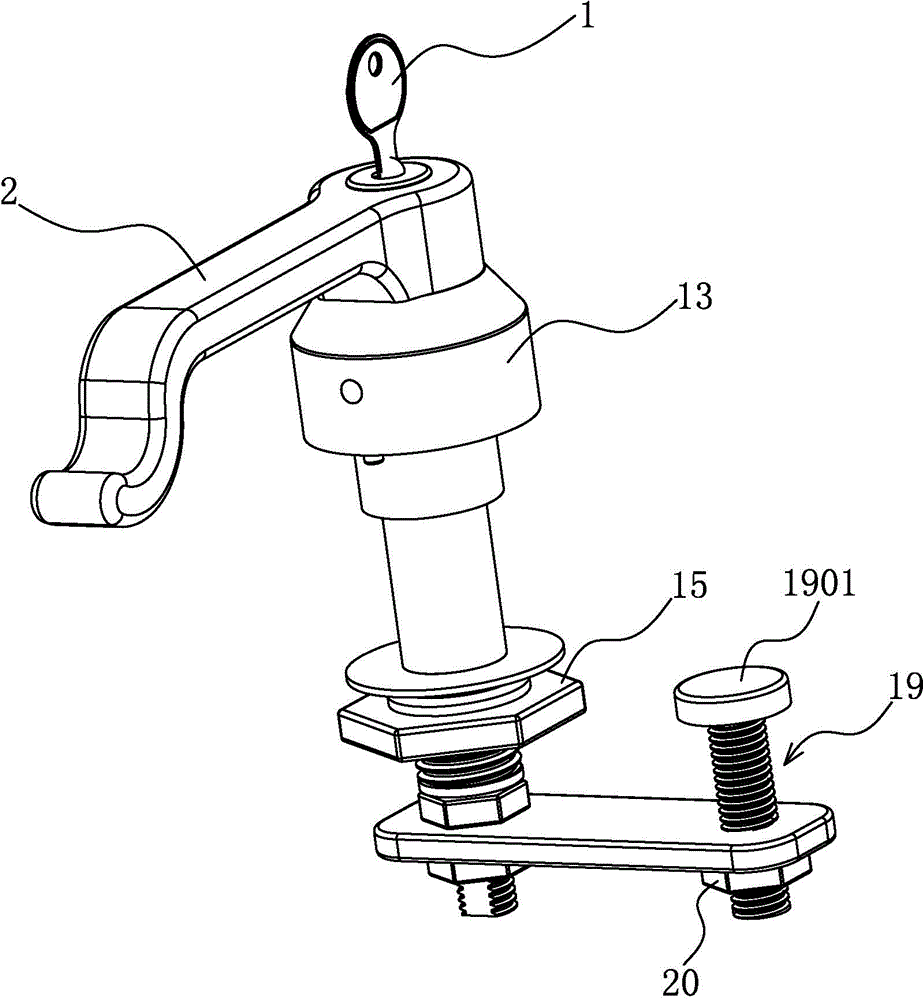

[0020] Now in conjunction with accompanying drawing, the present invention will be further described.

[0021] Such as figure 1 As shown, the tightness adjustment lock without a cold bridge wrench includes a handle 2 , a handle base 13 , a lock body, a rotating shaft 12 , and a rotating tongue 18 .

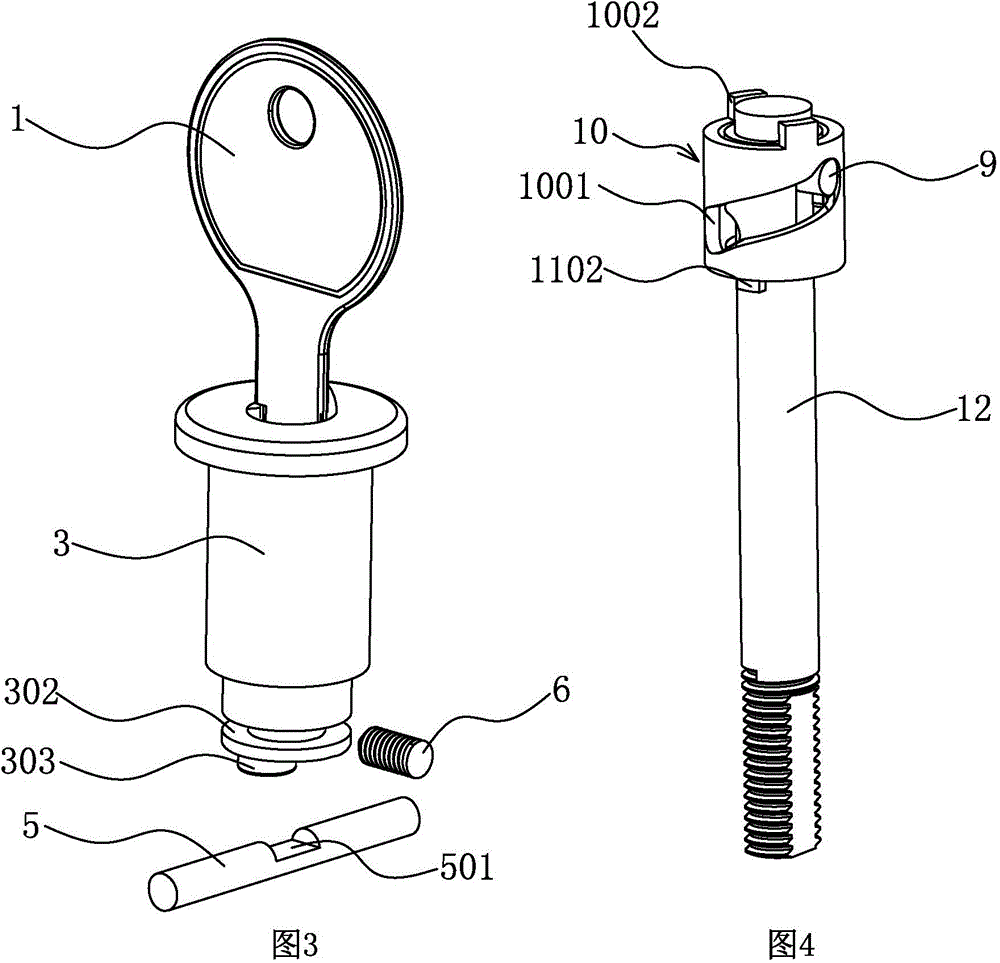

[0022] The lock body is composed of a lock cylinder 3, a lock seat 4, and a pin 6. The circumference of the lock cylinder is provided with an annular positioning groove 302, the circumference of the top of the lock cylinder is provided with a limit block 301, and the lock base is provided with a hole corresponding to the annular positioning groove. , the end of the lock base is provided with a limit groove 403 that slides with the limit block near the opening of the lock core, and the pin passes through the lock base and slides with the annular positioning groove to realize the positioning and rotation of the lock core and the lock base. The end of the lock cylinder is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com