Lifting and installation method of buckling restrained braces

A technology of buckling restraint and installation method, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems of difficult control of installation accuracy, cumbersome installation methods, and high labor intensity, so as to achieve convenient and fast construction projects and improve On-site installation efficiency and the effect of reducing installation risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

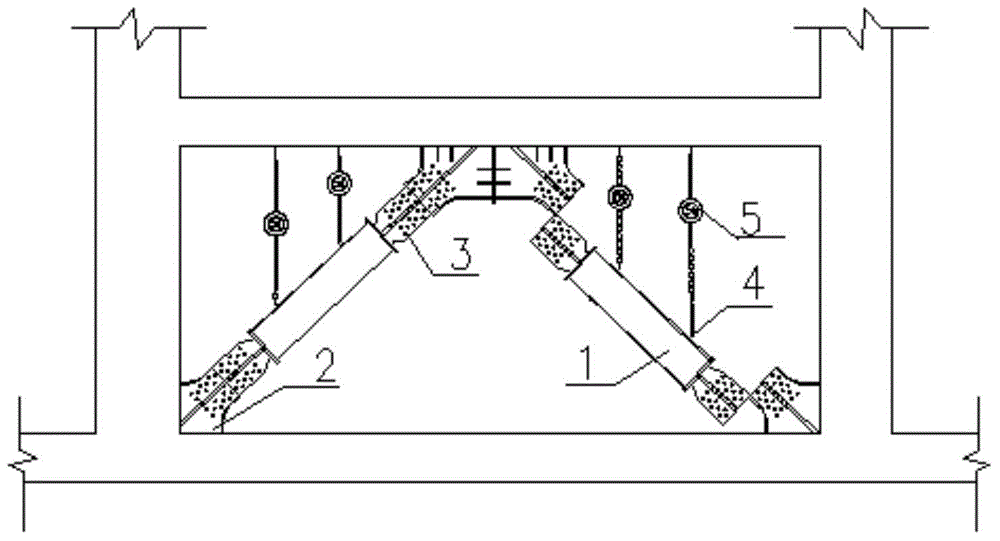

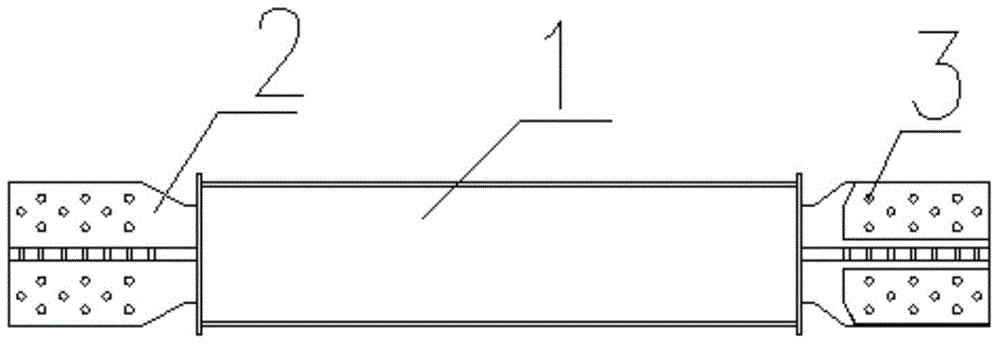

[0012] Referring to the attached figure, a hoisting and installation method of the buckling restraint support, the buckling restraint support 1 is hoisted first, the lifting lugs 4 on both sides of the buckling restraint support 1 should be left in advance, and two on each side, when hoisted until the installation When entering the floor, the rope tied in advance on the support is pulled into the floor. When the buckling restraint support 1 enters the floor, a round steel pipe needs to be prepared under it, and then a hydraulic forklift is used to move it to the place to be installed. , the hand-push hydraulic forklift will put it into the center of the buckling-restrained support. At this time, the electric hoist on the beam is used to lift the buckling-restrained support and connect it with the embedded components on the beam and column. Finally, the cover plate is bolted to connect the After the installation of the buckling restraint support is completed, the gusset plate 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com