A combined foundation structure system with four cylindrical foundations with supports

A combined foundation and cylindrical foundation technology, which is applied in the field of basic structures where multiple cylinders are combined to optimize the stress on the cylindrical foundation, can solve the problems of many construction constraints for large-diameter single-cylinder foundations, complex environment of offshore wind power generation infrastructure, The problem of large diameter of the type foundation, etc., can achieve the effect of clear force system, good structure force effect, and increase of the overall rigidity of the structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

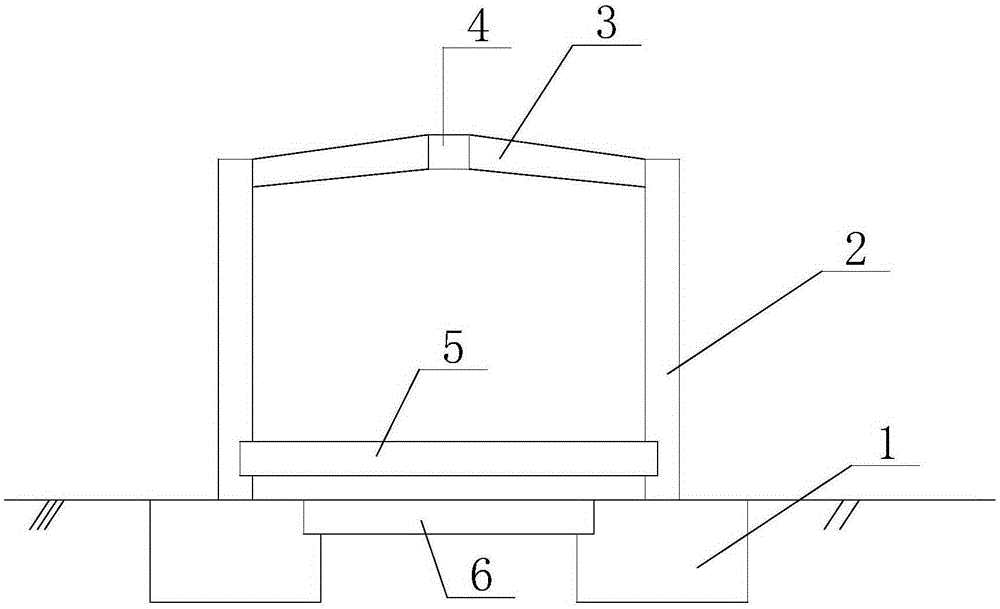

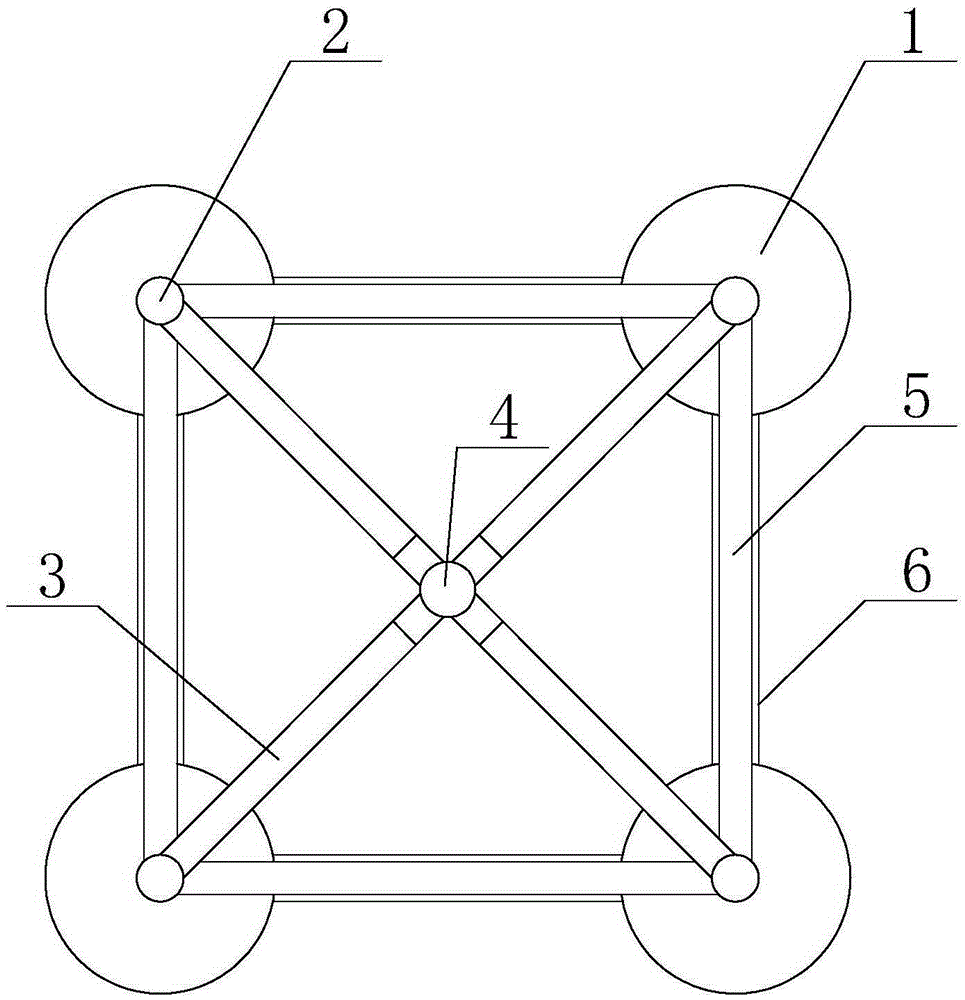

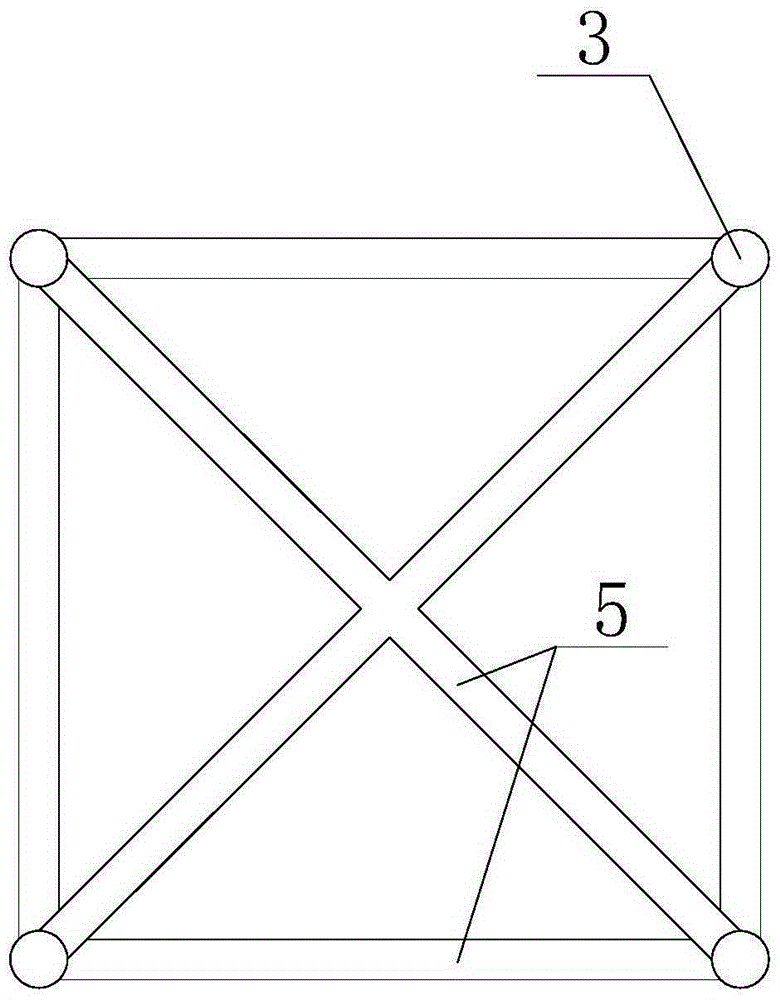

[0027] like figure 1 and figure 2 As shown, this embodiment discloses a combined foundation structure system with four supported cylindrical foundations, including four identical cylindrical foundations 1, four identical pile bodies 2, and four identical shaped steel beams 3 , node connecting piece 4, eight pile supports 5 and four identical tube supports 6 .

[0028] Cylindrical foundation 1 is a cylindrical steel structure foundation with a closed top and an open bottom. The outer diameter is 10m, the wall thickness is 25mm, the top cover is 50mm thick, and the cylinder height is 6m. The interior is divided into multiple compartments by setting compartment plates . The diameter of the cylindrical foundation 1 is usually 10-15m, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com