Coiled material tension control system

A tension control, coil technology, applied in the direction of winding strip, thin material handling, transportation and packaging, etc., can solve the problems of limited adjustment stroke, easy material breakage, complex structure and debugging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

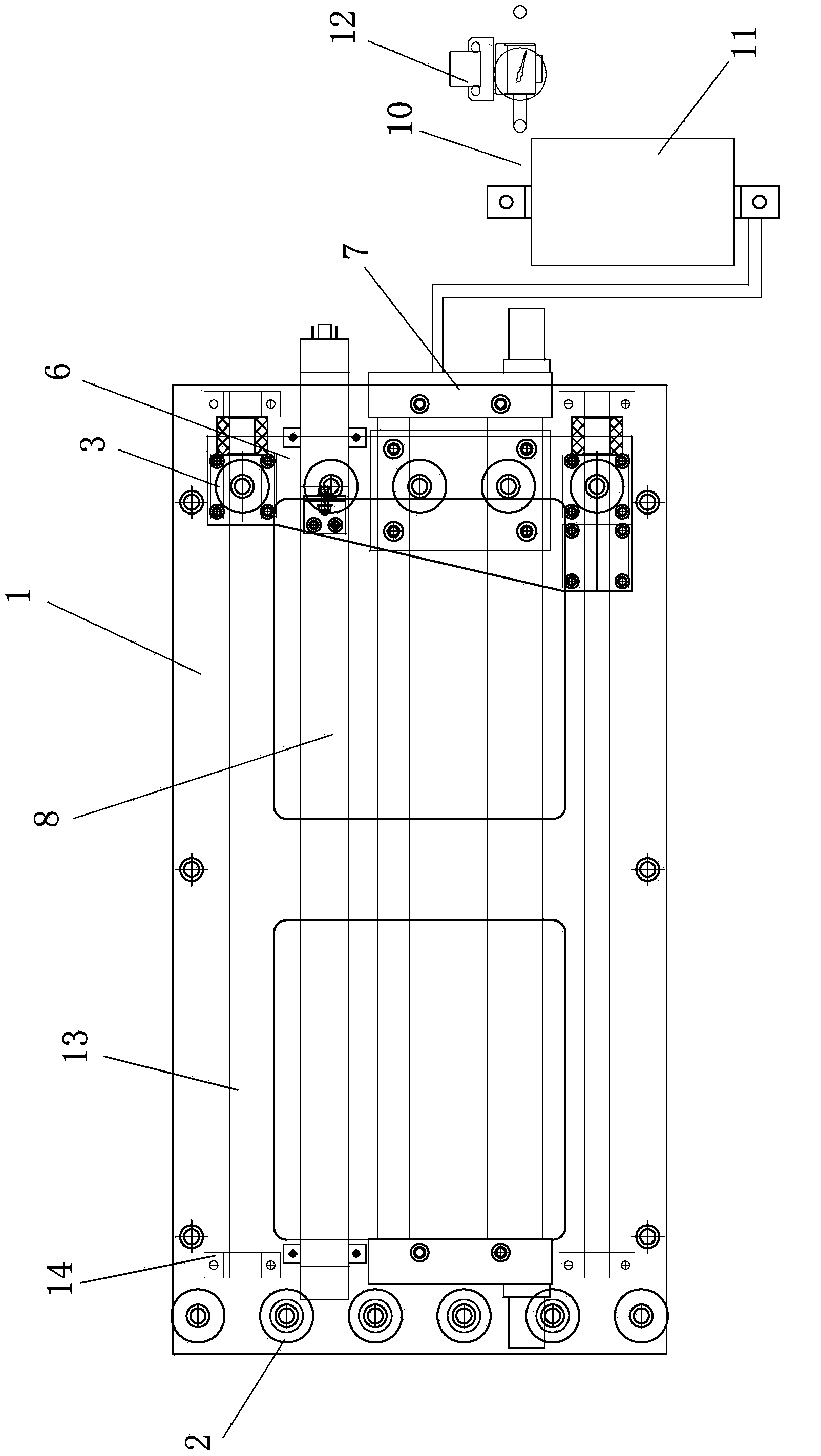

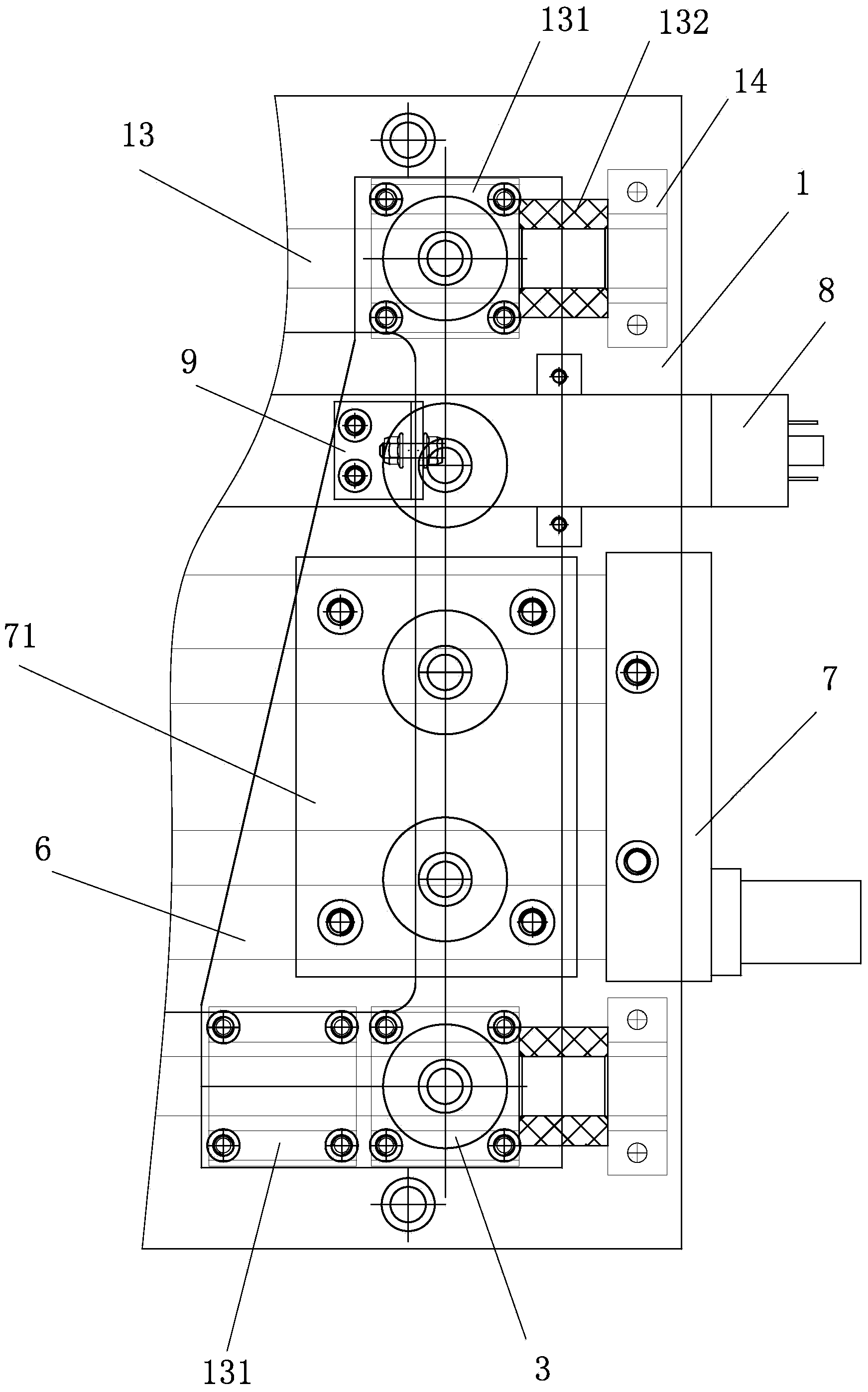

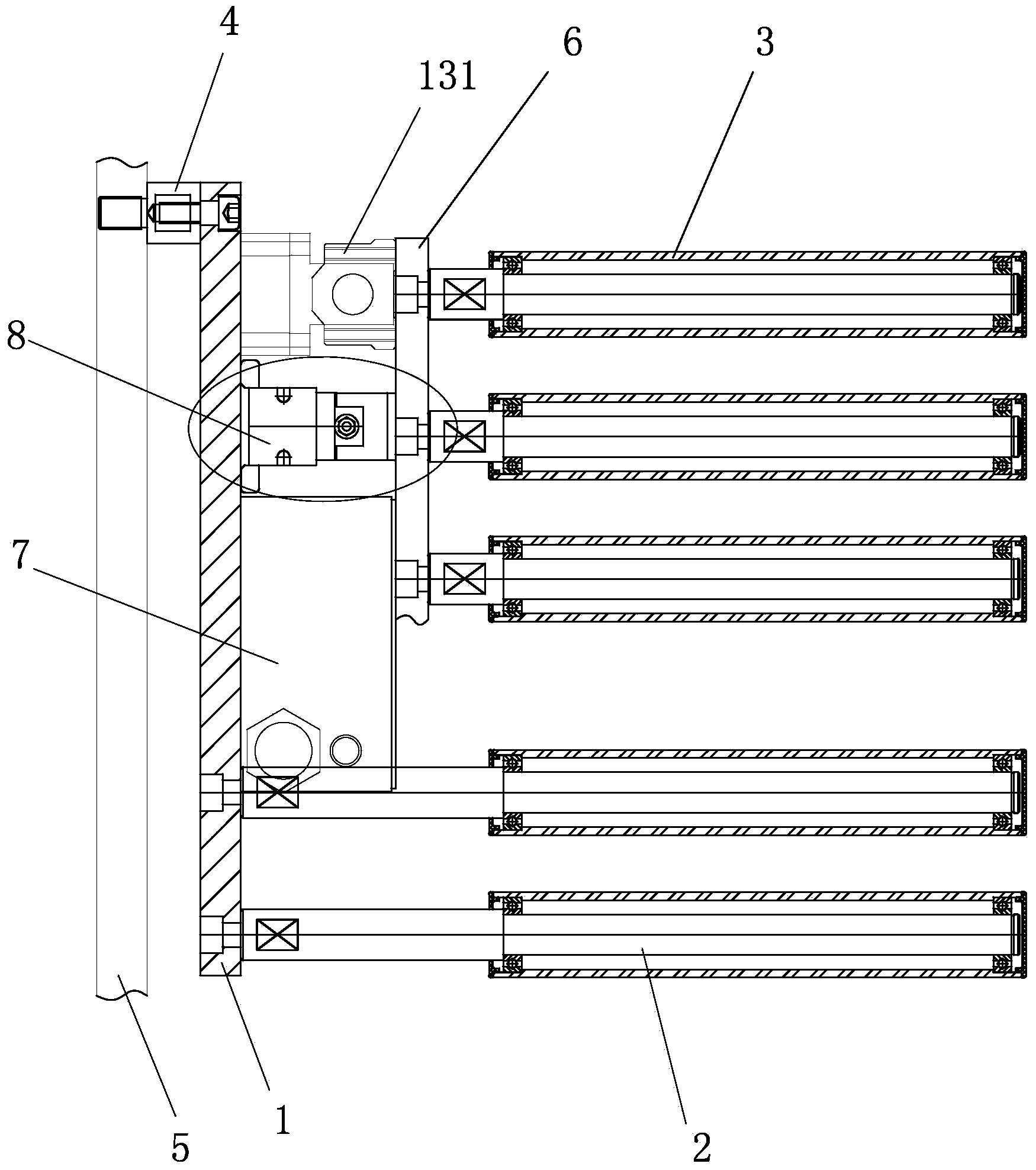

[0024] see Figure 1 to Figure 5 , a coil tension control system, comprising a fixed plate 1, a fixed roller 2 and a movable roller 3, the fixed plate 1 is installed on an upright frame wall plate 5 through a support column 4, the fixed plate 1 is a rectangular plate, and its Length is greater than height. The fixed rollers 2 and the movable rollers 3 are respectively located in groups on the left and right sides of the fixed plate 1 . The fixed rollers 2 and the movable rollers 3 are longitudinally arranged in the shape of "1", and the fixed rollers 2 and movable rollers 3 on both sides are arranged alternately in the height direction. The number of the movable rollers 3 is less than that of the fixed rollers 2, and the fixed rollers 2 pass through The shaft is rotatably fixed on the fixed plate 1 , the movable roller 3 is parallel to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com