Hanging type track freight transport system

A hanging and rail technology, applied in the field of rail freight, can solve the problems of inability to form a rail transportation network and weak transportation capacity, and achieve the effects of improving the workshop logistics environment, convenient transportation and high transportation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

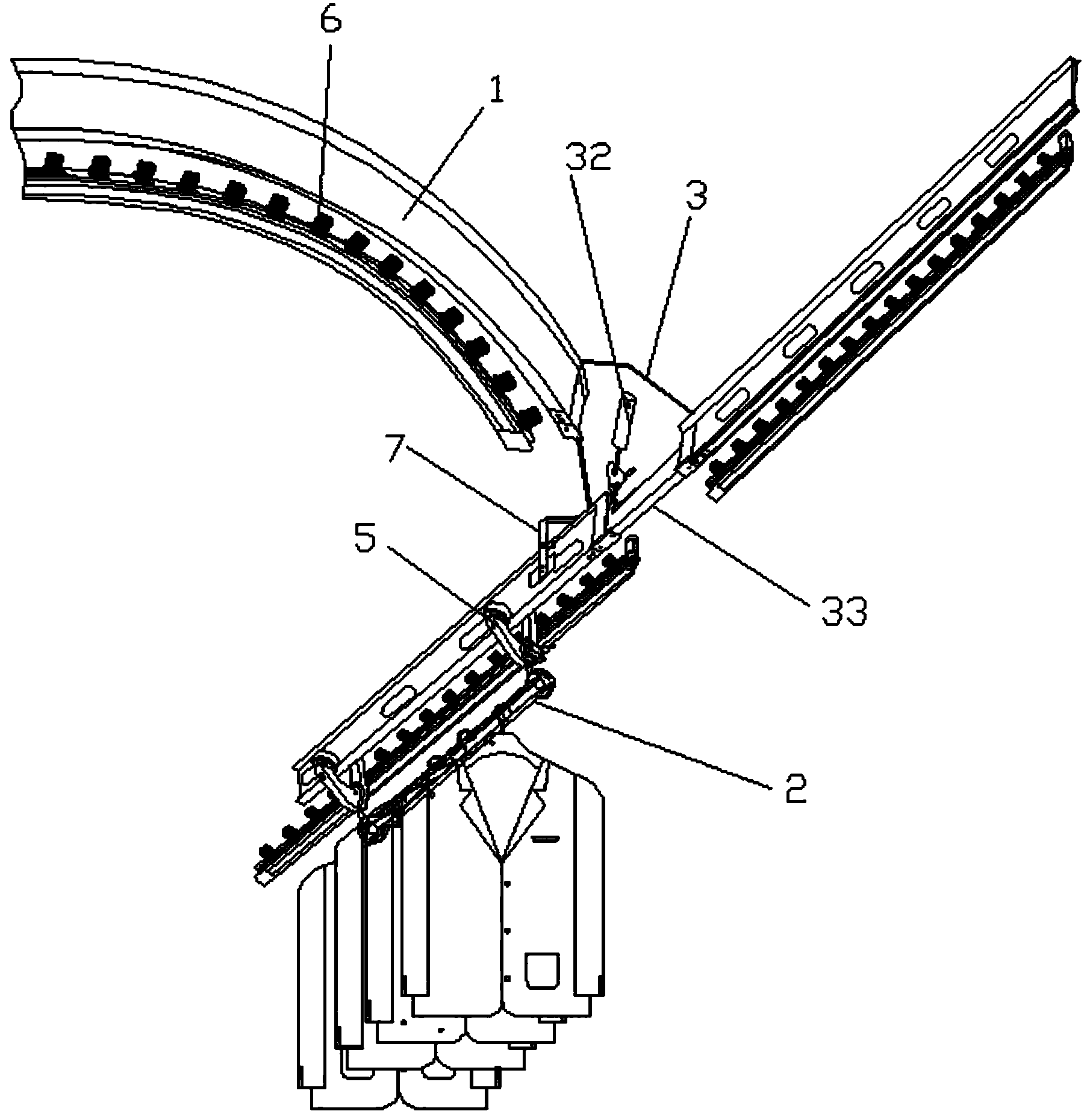

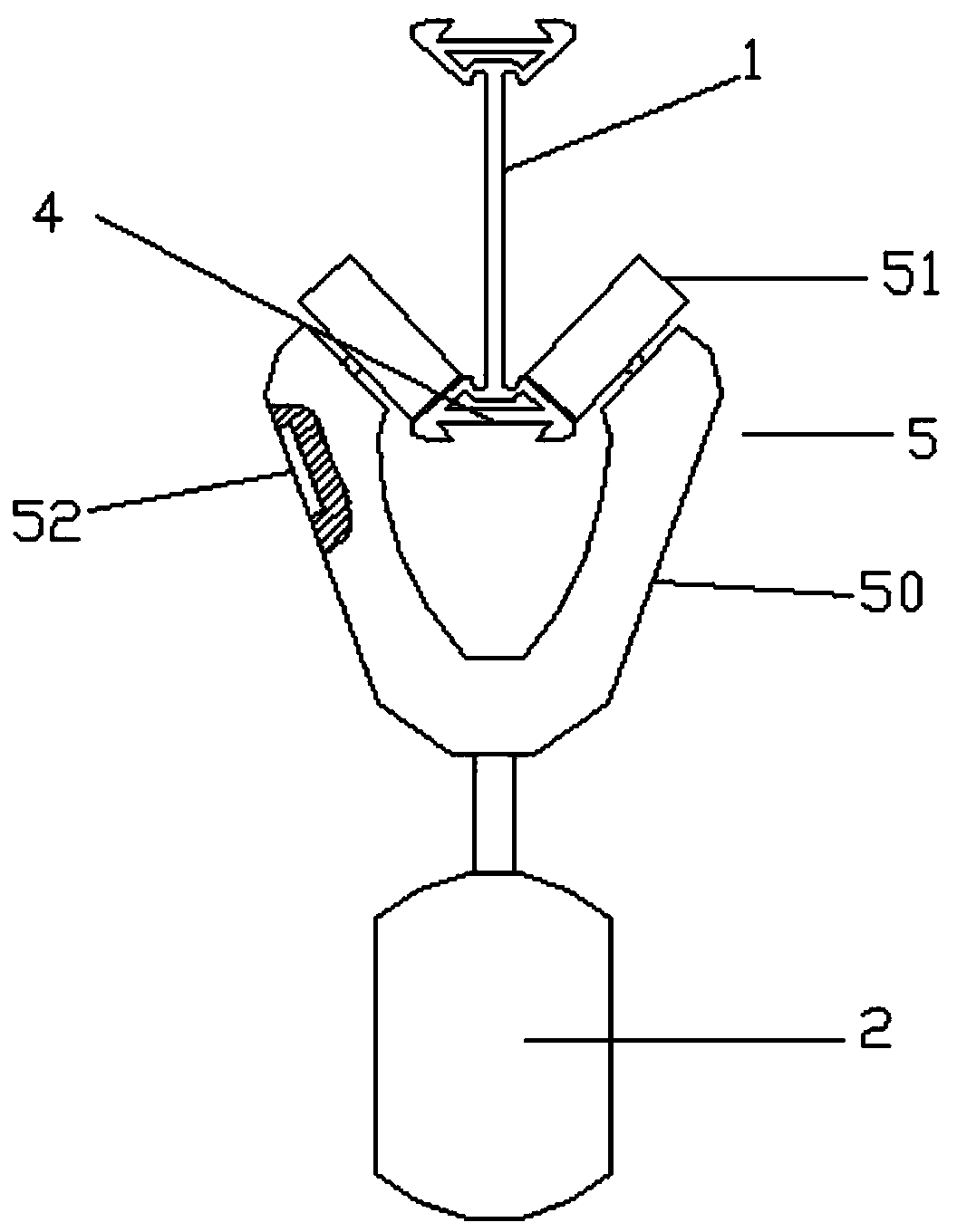

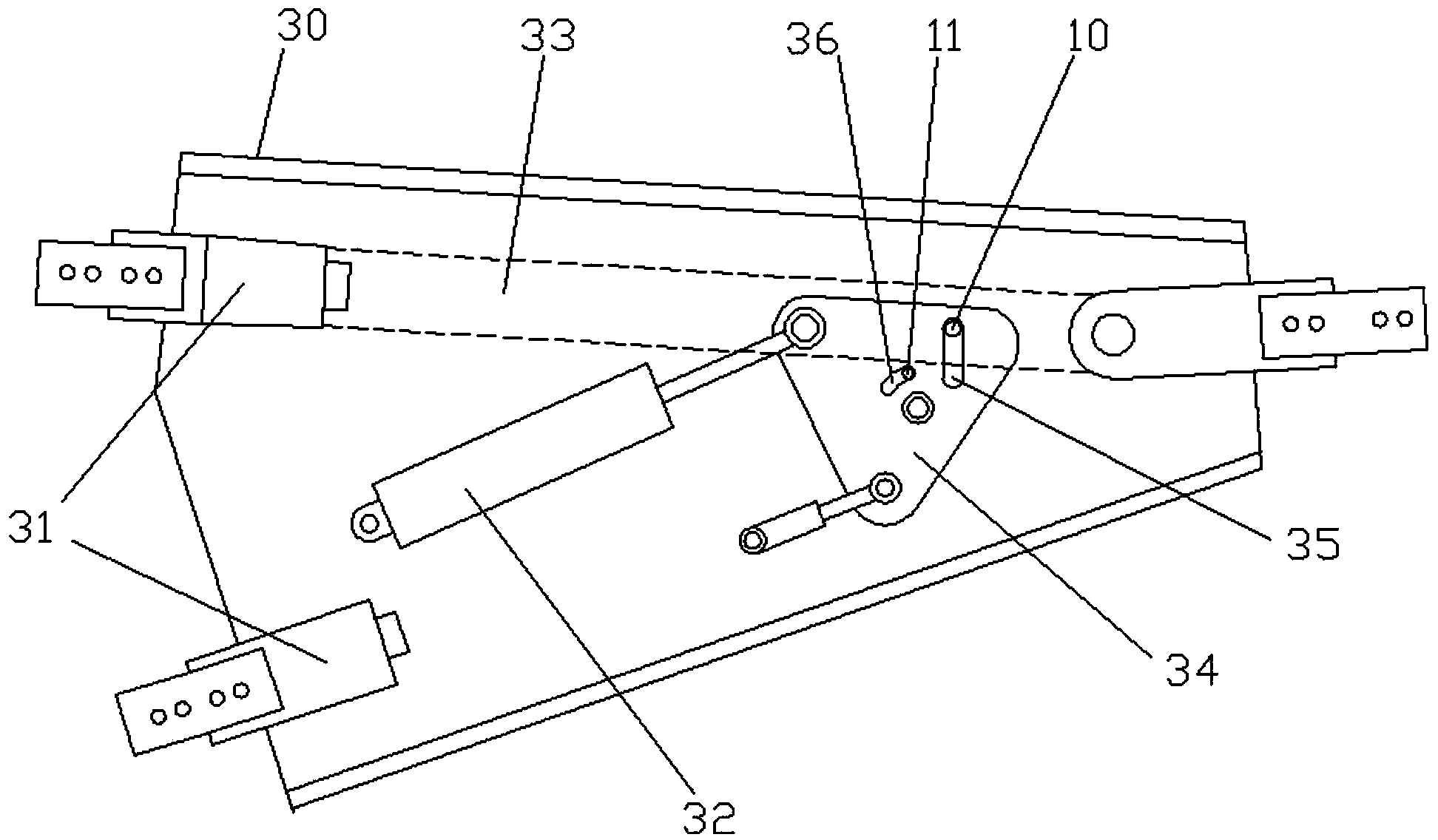

[0025] Such as figure 1 A hanging track freight system shown includes several tracks 1 and cranes 2, the tracks are interwoven into a net shape, and the tracks are connected by beams 12 and then suspended on the ceiling, as Figure 7 As shown, it can also be installed on the ground with support poles, such as Figure 8 As shown, there are many types of cranes, and different cranes can be selected according to the needs of transporting items, such as figure 1 The crane in it is convenient for hanging clothes, while Figure 9 The crane in is convenient for storing parts and components, and the track in this embodiment is according to Figure 5 The state shown in the installation, the crane in this embodiment adopts figure 1 The crane shown in ; the track is provided with a crane propulsion mechanism 6, and the tracks are connected in a Y shape, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com