Automatic buffering anti-jamming oil pressing device of domestic oil press

A technology of oil press device and oil press machine, applied in the direction of presses, manufacturing tools, etc., can solve the problems of non-rotation, low power, jamming, etc., and achieve the effect of reducing the repair rate and ensuring the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

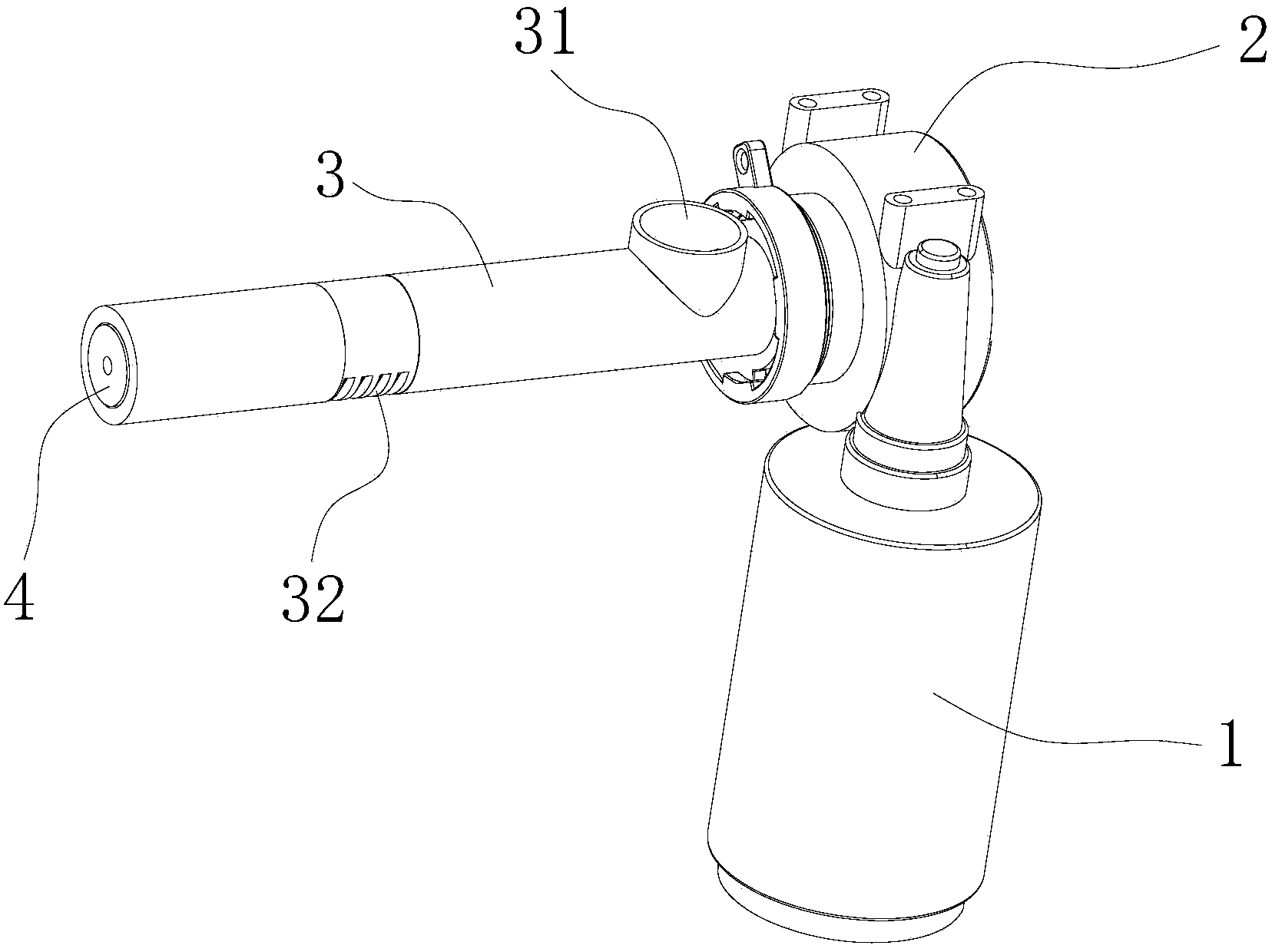

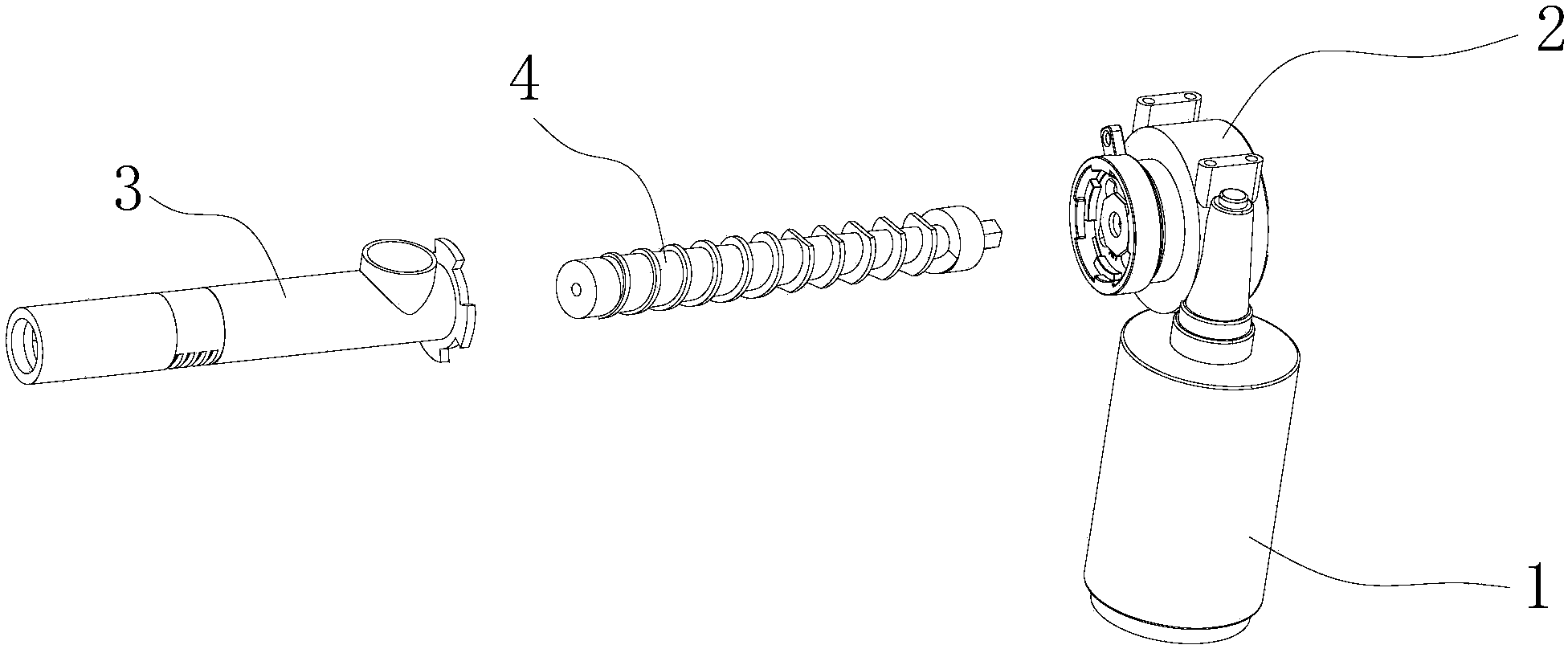

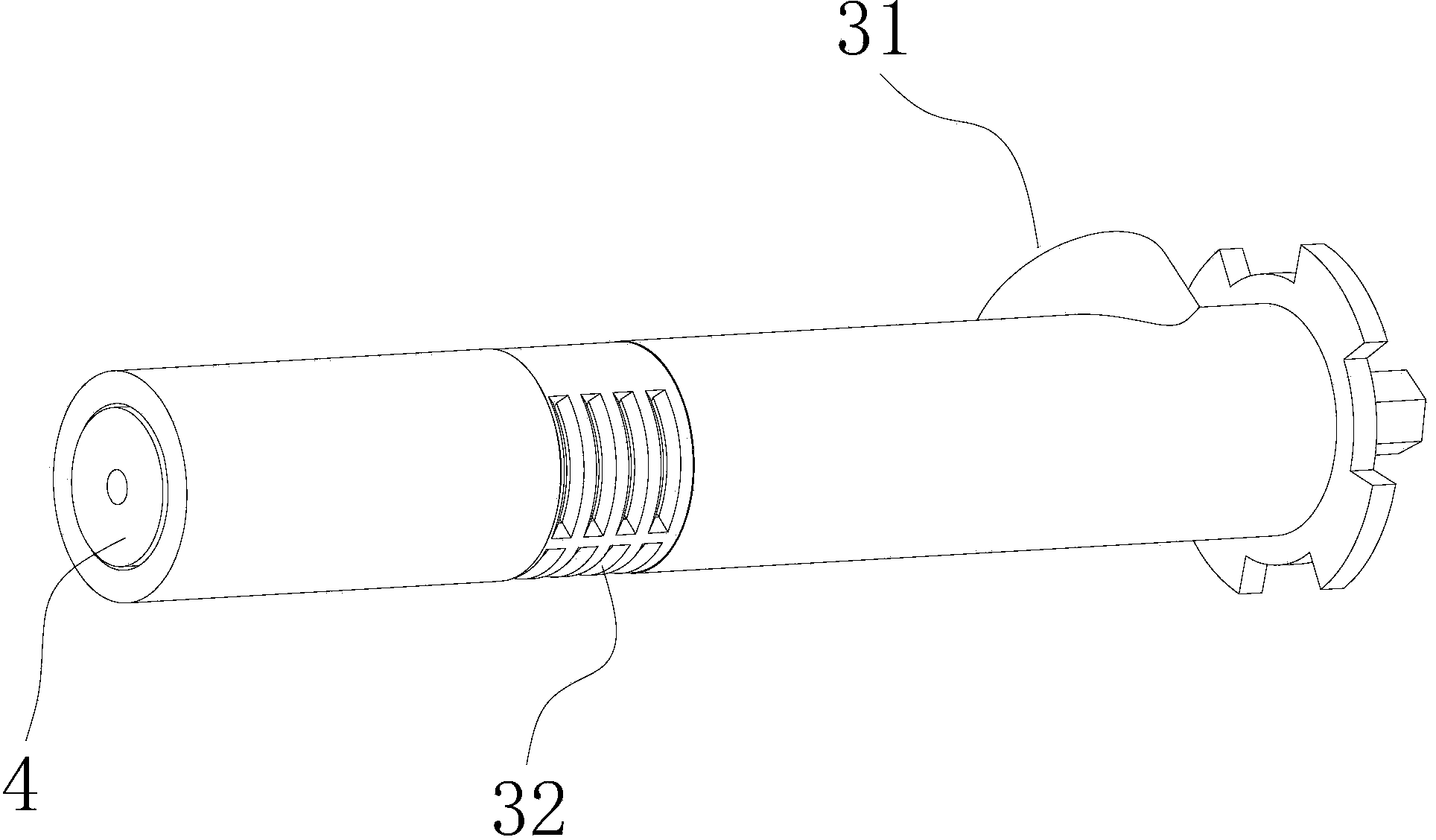

[0028] Please refer to Figure 1-7 , the household oil press automatic buffer anti-jamming machine oil press device of the present invention comprises a motor 1, a gear mechanism 2, a press chamber 3, and a press bar 4. The pressing chamber 3 is provided with a feeding port 31 and an oil outlet 32. The feeding port 31 is used to receive the oil extraction raw material dropped from the outlet of the feeding device, and the oil outlet 32 can be used for the squeezed oil to flow out. The oil outlet 32 is a plurality of slits in two rows (see image 3 ); Press bar 4 is provided with screw thread 41, connecting end 42. During oil extraction, the squeeze rod 4 is sleeved in the squeeze chamber 3, and the connecting end 42 of the squeeze rod 4 is clamped to the gear mechanism 2, and the end of the squeeze chamber 3 close to the gear mechanism 2 is locked and fixed, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com