Expansion device for heat exchange tubes and cooling fins

A technology of heat exchange tubes and heat sinks, which is applied in the mechanical field, can solve problems such as poor sealing, poor expansion effect, and unstable pressure, and achieve good expansion effect, stable expansion, and convenient disassembly and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

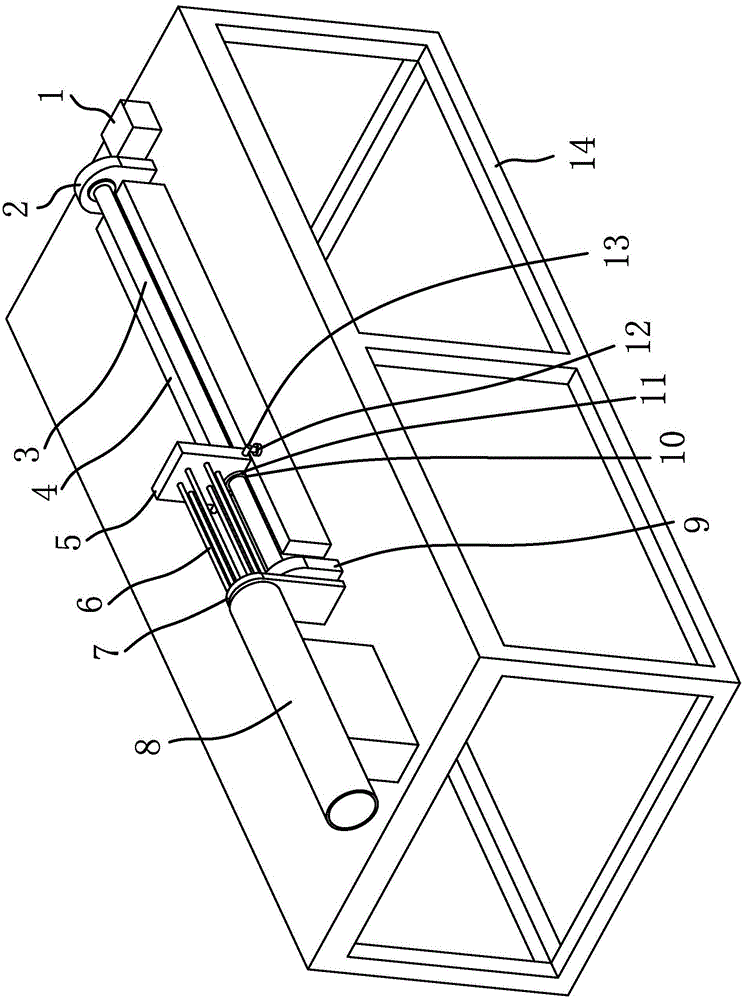

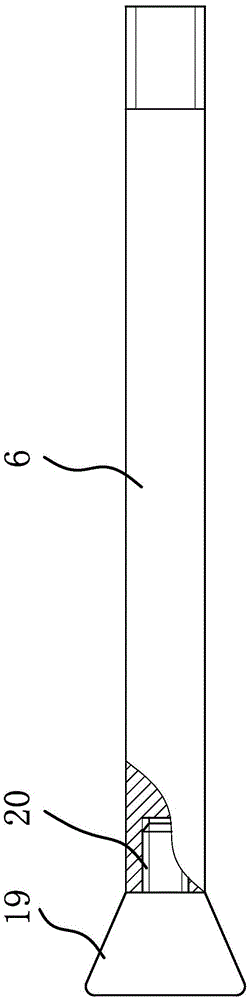

[0038] Such as figure 1 , image 3 , Figure 4As shown, the expansion joint device of the heat exchange tube and the heat sink includes a workbench 14 and an expansion rod 6, and the material of the expansion rod 6 is made of stainless steel; the workbench 14 is provided with a positioning cylinder 8, and the positioning cylinder 8 is fixed on the working One side of the platform 14; one end of the positioning cylinder 8 has an opening, the other end of the positioning cylinder 8 is fixed with a positioning plate 7, and the outer diameter of the expansion rod 6 is smaller than the inner diameter of the heat exchange tube 21, so that the expansion rod 6 can be inserted into the heat exchange tube 21 Expansion rod 6 one ends are fixed with expansion head 19, and expansion rod 6 other ends are connected with a moving mechanism that can drive its axial movement, and the section of expansion head 19 is conical shape, and the material of expansion head 19 adopts stainless steel, ca...

Embodiment 2

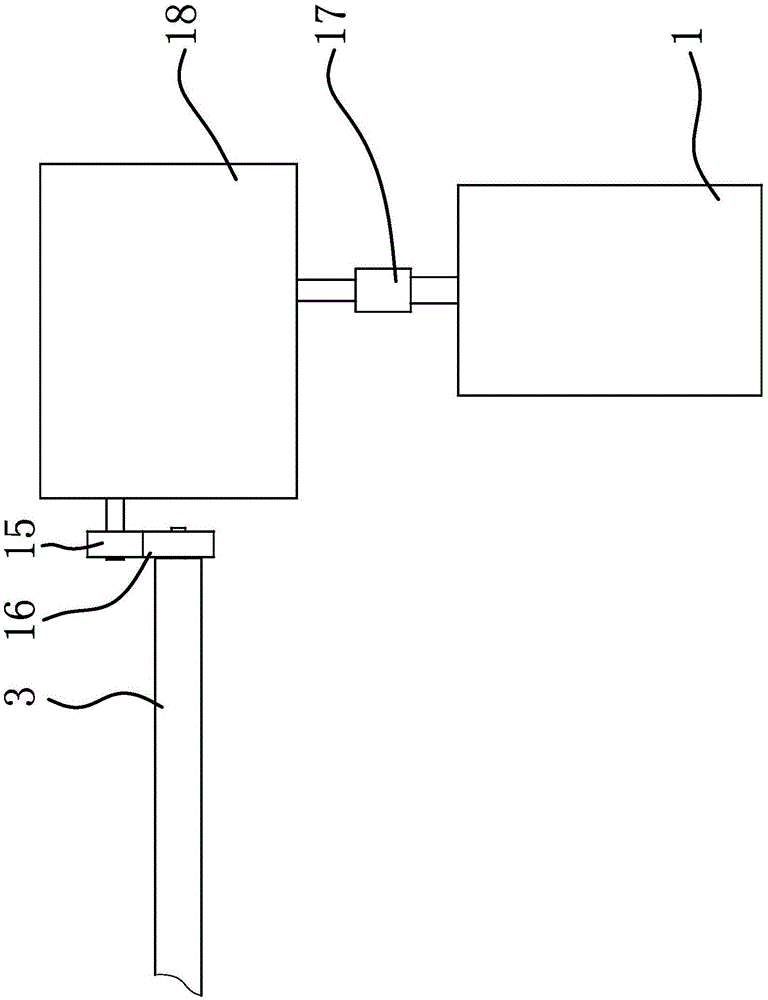

[0047] The content in this embodiment two is roughly the same as that in embodiment one, the difference is that the moving mechanism in embodiment one includes motor 1, screw mandrel 3, nut 10, bearing one 11 and connecting plate 5, and motor 1 is fixed On the workbench 14, both ends of the screw rod 3 are fixed on the workbench 14 by means of axial fixing and circumferential rotation, the output shaft of the motor 1 is connected with the screw rod 3 through a transmission structure, and the nut 10 is screwed on the On the screw mandrel 3, the bearing one 11 is set outside the nut 10, and the inner ring of the bearing one 11 is fixed to the nut 10, the connecting plate 5 is fixed on the outer ring of the bearing one 11, the expansion rod 6 is fixed on the connecting plate 5, and the transmission Structure comprises reducer 18, driving gear 15 and driven gear 16, the input end of reducer 18 and the output shaft of motor 1 are connected by coupling 17, and driving gear 15 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com