Immersed screen and method of operation

A submerged membrane and filter technology, which is applied in chemical instruments and methods, separation methods, mixing methods, etc., can solve the problems of reducing filter density and filter backwashing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

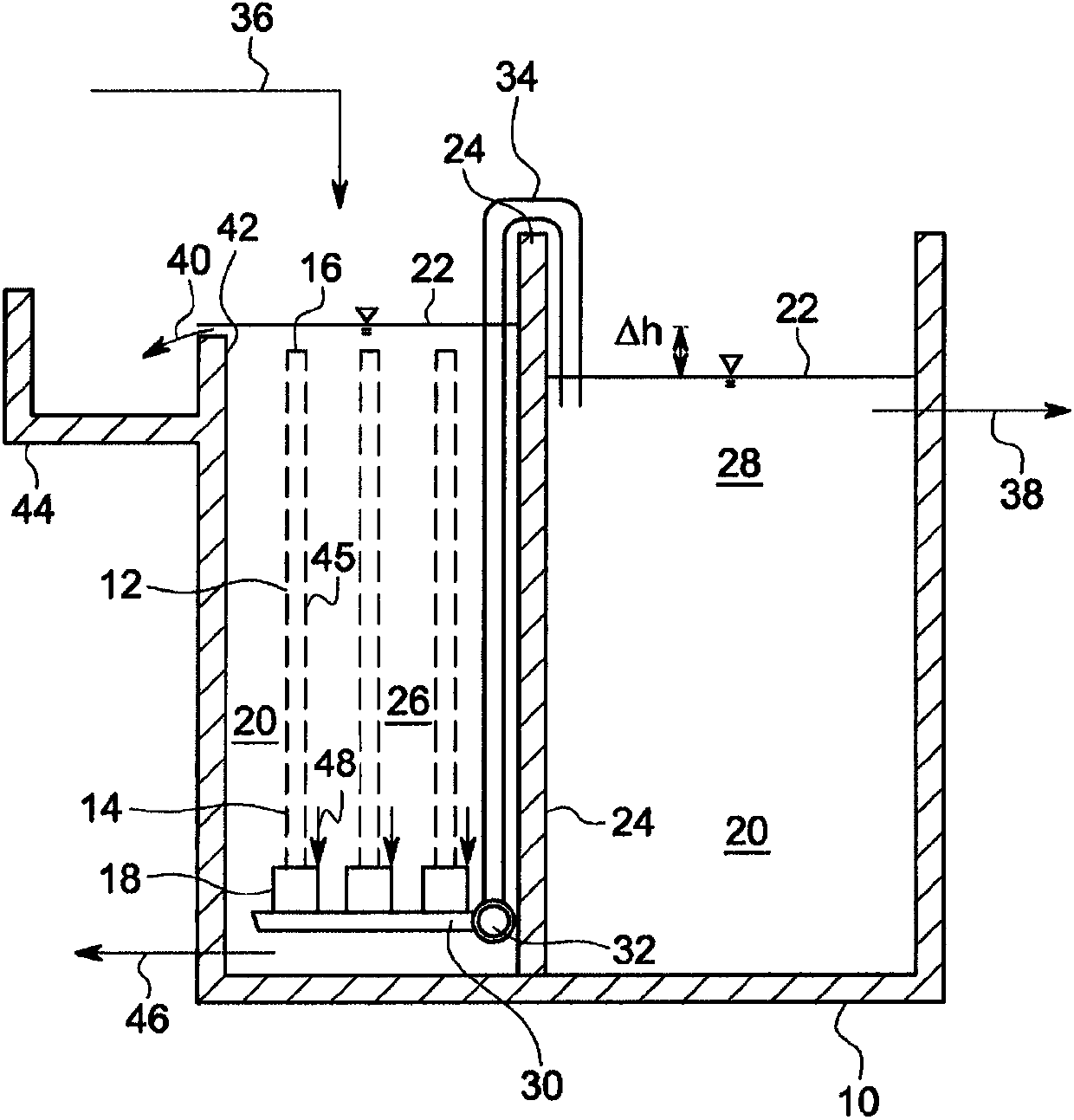

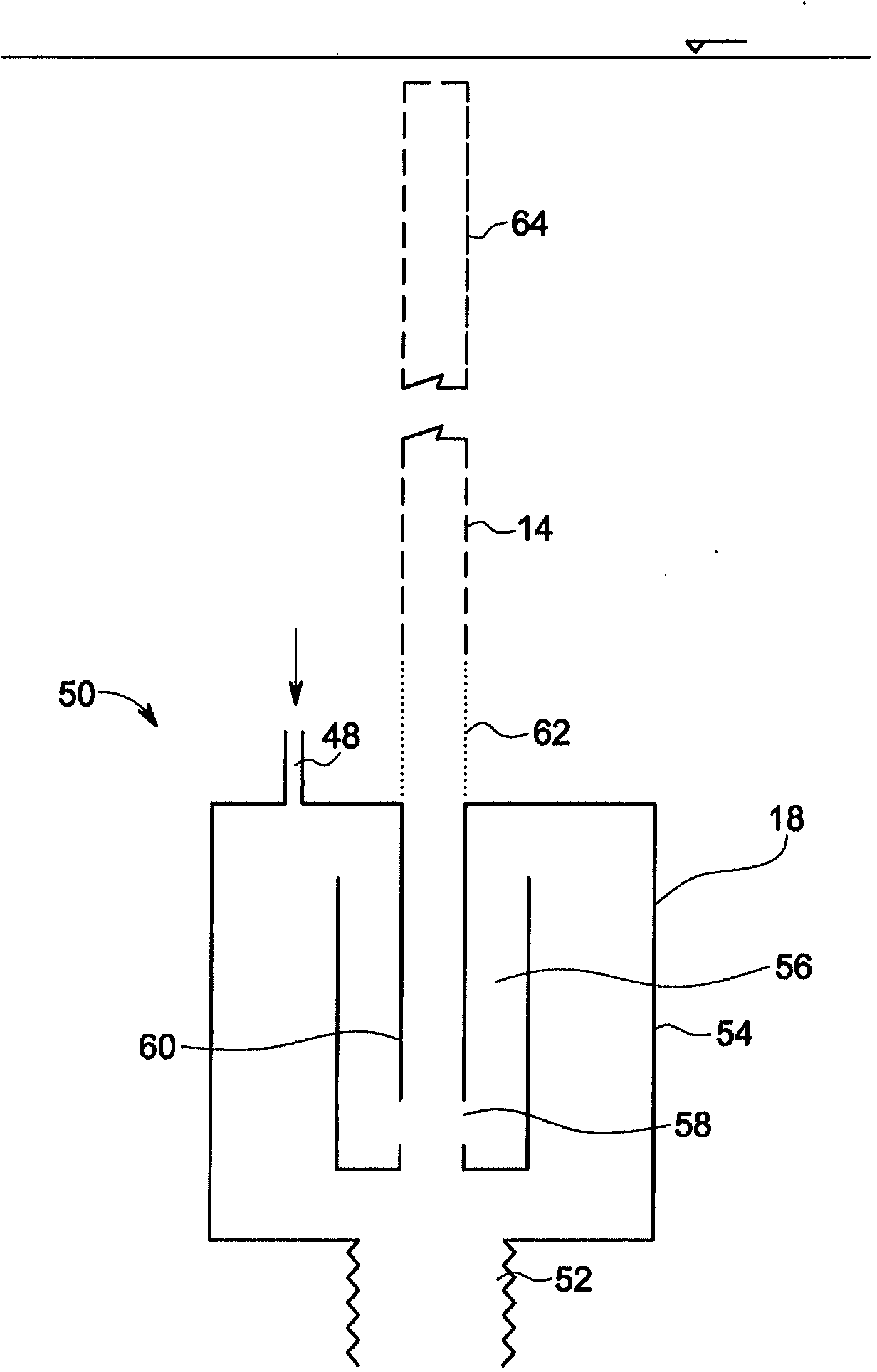

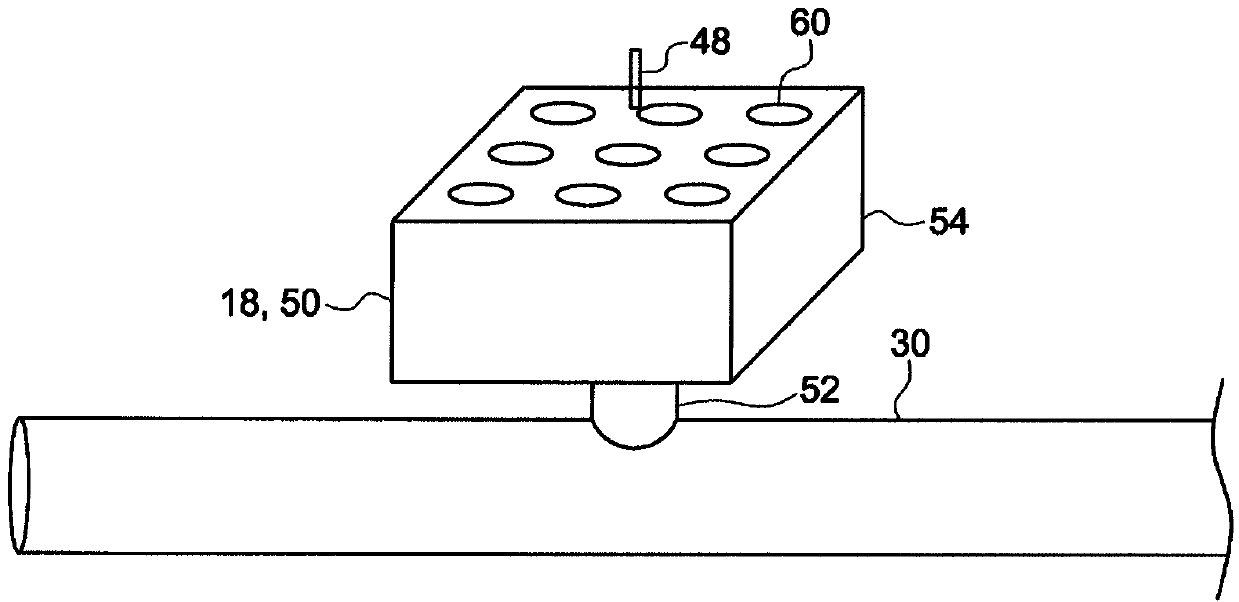

[0011] figure 1 Tank 10 containing static screen 12 is shown. The static sieve 12 has a plurality of filter bodies 14 . Each filter body 14 may be made from one or more layers of plastic or metal mesh that is rolled or folded into a prismatic conduit such as a tube. The top of the filter body 14 is covered by a cover 16 . The filter body 14 is open at the bottom and is attached to a pulse generating aerator 18 . As described further below, the pulse generating aerator 18 acts as an air driven backwashing device. A pulsating aerator 18 releases a slug of air or optionally a biphasic fluid into the filter body 14 from time to time. Although the pulsed aerator 18 will be described as operating with air, other gases may also be used.

[0012] The tank 10 is an aqueous open tank 20 having a free surface 22 upstream and downstream of a dividing wall 24 . A dividing wall 24 divides the tank 10 into an upstream portion 26 and a downstream portion 28 . Optionally, the downstream...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com