Flat integrated cable

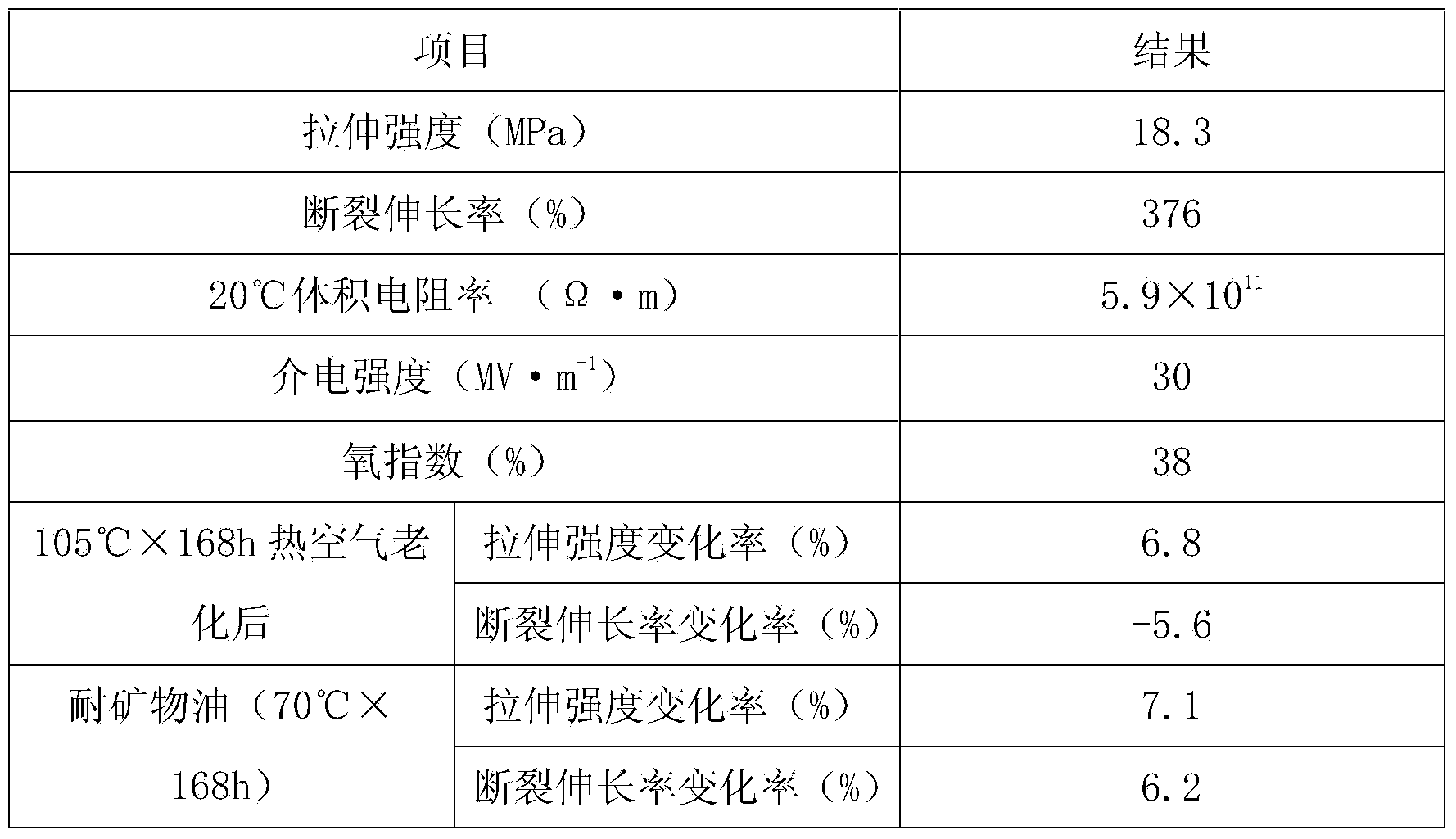

A flat cable and body shape technology, applied in the field of conjoined flat cables, can solve the problems of large change rate of tensile strength and elongation at break, high requirements for anti-interference performance of conductors, and poor oil resistance of cable materials. The effect of small change in tensile strength and elongation at break, simplified laying process, and excellent oil resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

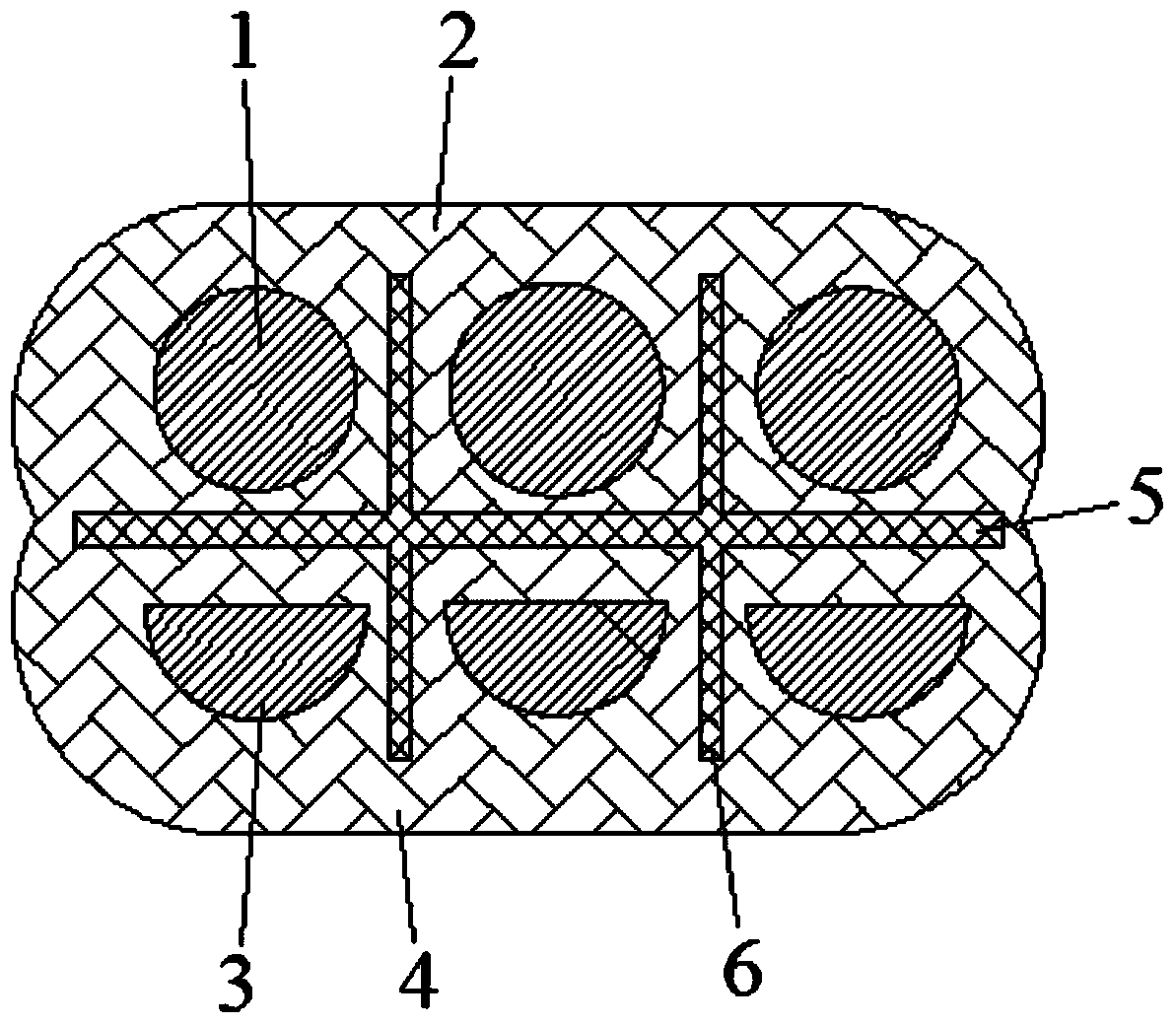

[0015] see figure 1 , a conjoined flat cable, including upper and lower flat cables, the upper flat cable includes a plurality of circular conductors 1 arranged side by side, the plurality of circular conductors 1 are covered with a first flat sheath 2, the lower The flat cable includes a plurality of semicircular conductors 3 arranged side by side, the plurality of semicircular conductors 3 are covered with a second flat sheath 4, the lower end of the first flat sheath 2 and the upper end of the second flat sheath 4 Connected as a whole, the joint of the first and second flat sheaths 2, 4 is provided with a transverse isolation strip 5 between the plurality of circular conductors 1 and the plurality of semicircular conductors 3, and the upper and lower sides of the transverse isolation strip 5 A plurality of longitudinal isolation strips 6 correspondingly extending between two adjacent circular conductors and two adjacent semicircular conductors are integrally connected respe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com