Attaching the blades of an axial turbocompressor to the compressor drum

A technology of axial flow turbines and blades, which is applied in the direction of machines/engines, supporting elements of blades, components of pumping devices for elastic fluids, etc., which can solve the problems of hard-to-reach clamping surfaces and complex processing, and achieve increased clearance , reduce the volume, simplify the effect of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In the following description, the terms inner and outer relate to a position relative to the axis of rotation of the axial turbine.

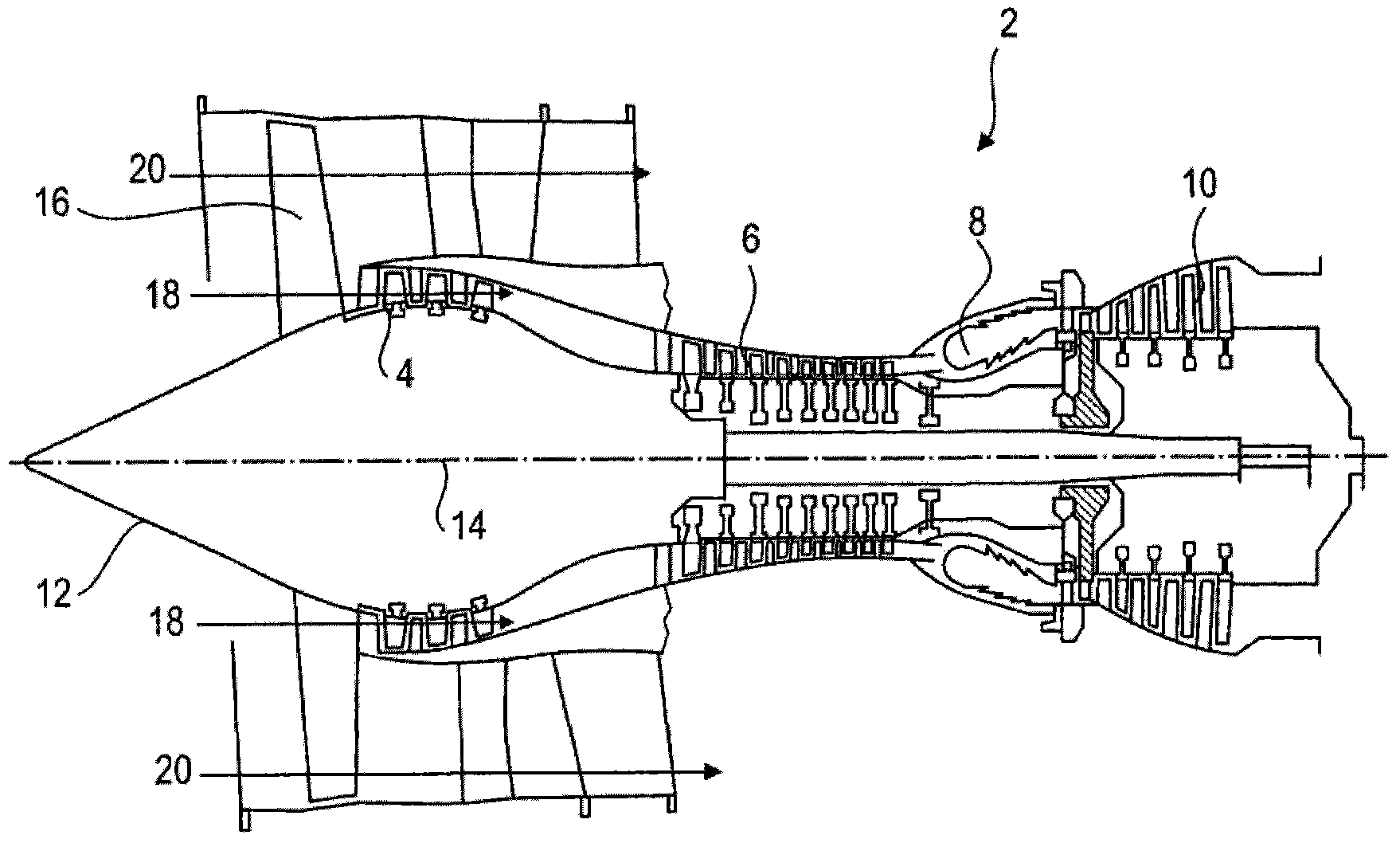

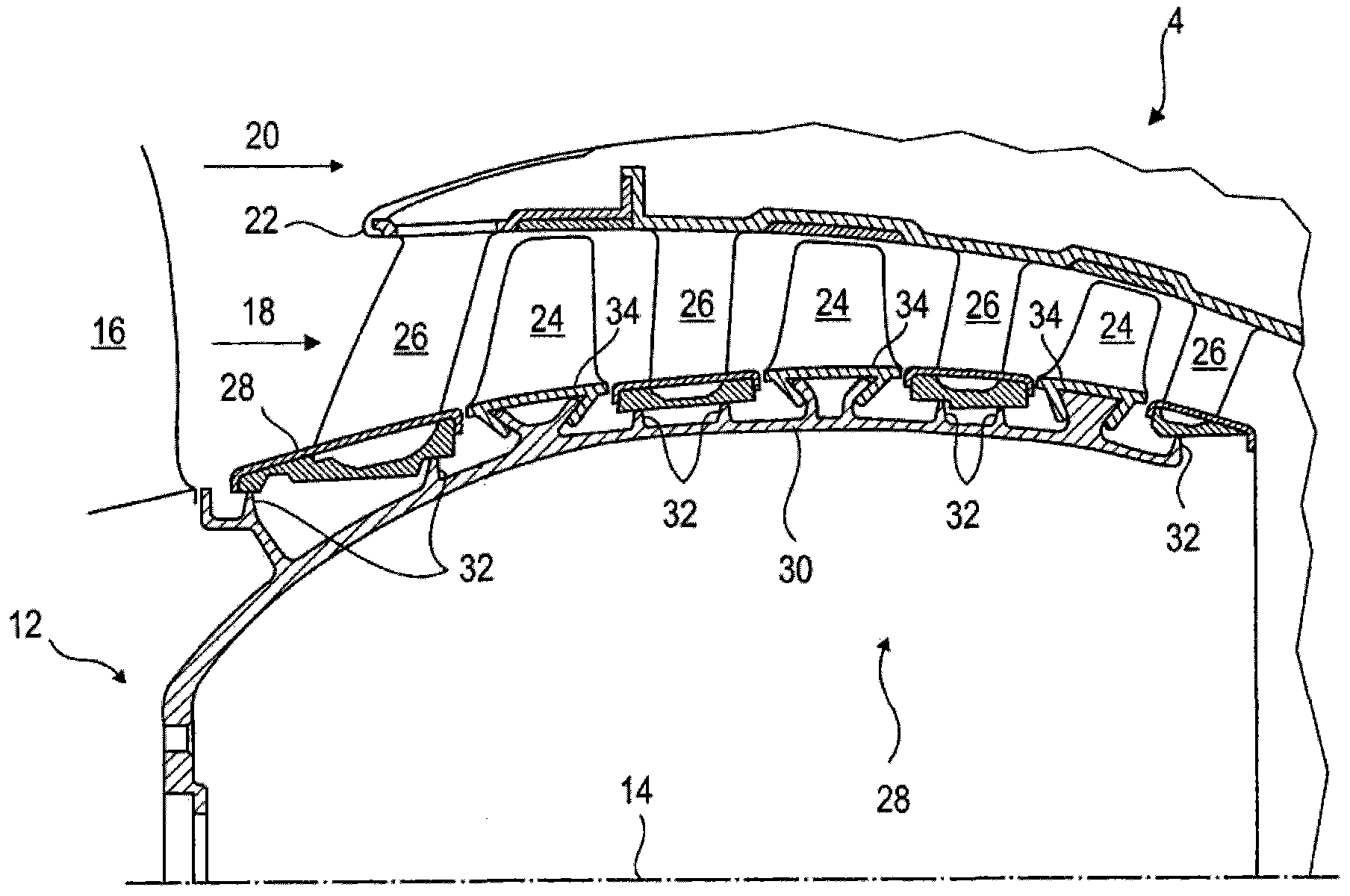

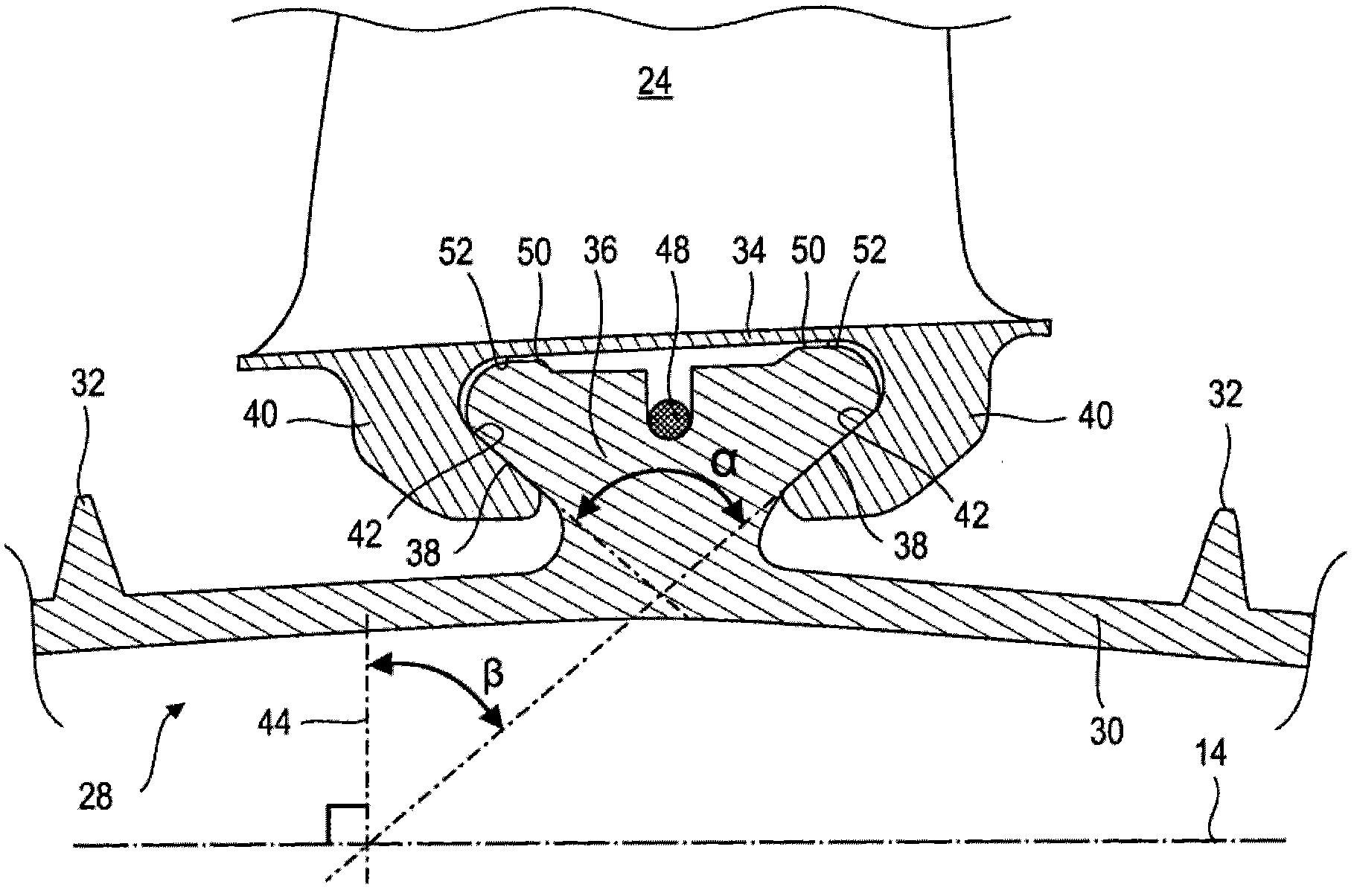

[0037] figure 1 An axial turbine is shown. In this case it is a twin-flow turbojet engine. The turbojet engine 2 comprises a first compression stage (called low pressure compressor 4 ), a second compression stage (called high pressure compressor 6 ), a combustion chamber 8 and one or more turbine stages 10 . In operation, the mechanical power of the turbine 10 is transmitted through the central shaft to the rotor 12 and drives the two compressors 4 and 6 . The reduced mechanism increases the rotational speed delivered to the compressor. Alternatively, each different turbine stage may be connected to the compressor stage by a concentric shaft. The compressor includes several rows of rotor blades associated with rows of stator blades. The rotation of the rotor 12 about its axis of rotation 14 thus generates a flow of air, compressing i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com