A hydraulic controller for common rail fuel injector with middle hole pressure accumulation

A common rail injector and pressure accumulator technology, which is applied in the direction of machines/engines, fuel injection devices, engine components, etc., can solve the problems of high cleanliness requirements, unfavorable popularization and application, and high processing costs, so as to reduce return Oil back pressure sensitivity, improved fuel injection accuracy, and reduced processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

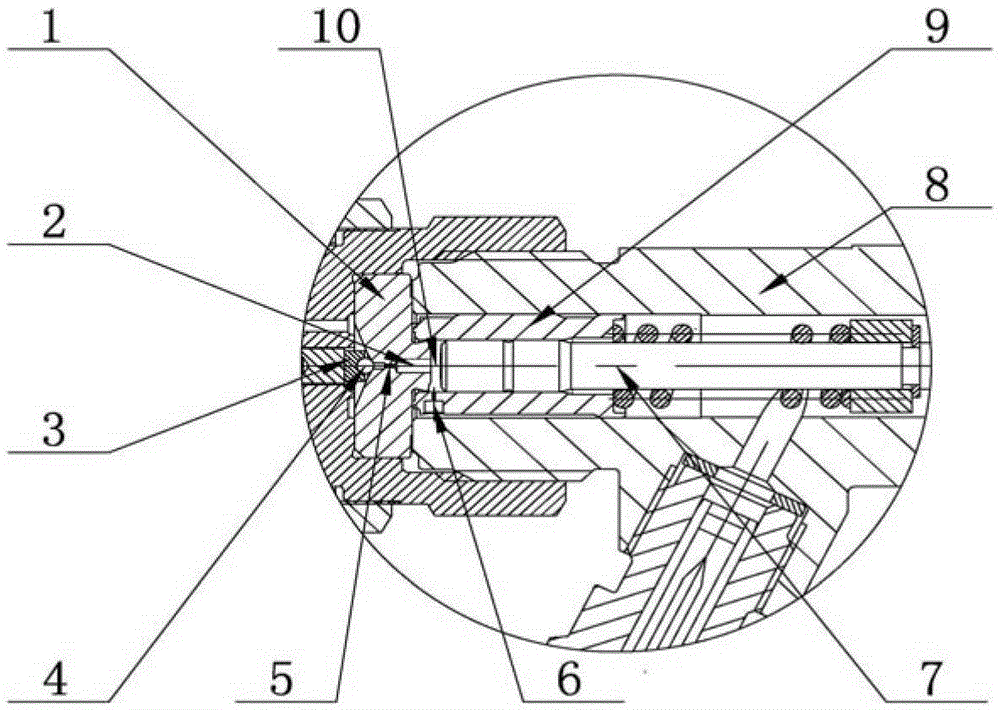

[0019] like figure 1 As shown, the present invention includes a conical ball valve switch valve, a control sleeve 9, a control plunger 7 and a spring, wherein the control sleeve 9, the control plunger 7 and the spring are all arranged in the middle hole of the fuel inlet end of the injector body 8 In the pressure accumulator chamber, one end of the control plunger 7 is inserted in the control sleeve 9 and is slidably connected with the control sleeve 9. The other end of the control plunger 7 is sleeved with a spring, and the two ends of the spring are respectively controlled by The counterbore at one end of the sleeve 9 is positioned with the spring seat arranged at the other end of the control plunger 7 . The conical ball valve type on-off valve is arranged at the end of the oil inlet end of the injector body 8 and accommodated in a nut threadedly connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com