Steel bar strapping machine

A binding machine and steel bar technology, which is applied in the processing of building materials, construction, building construction, etc., can solve problems such as low binding efficiency, reduced operating efficiency, and difficult torsion for workers, so as to ensure operating safety and improve operating efficiency. , the effect of reducing the amount of labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

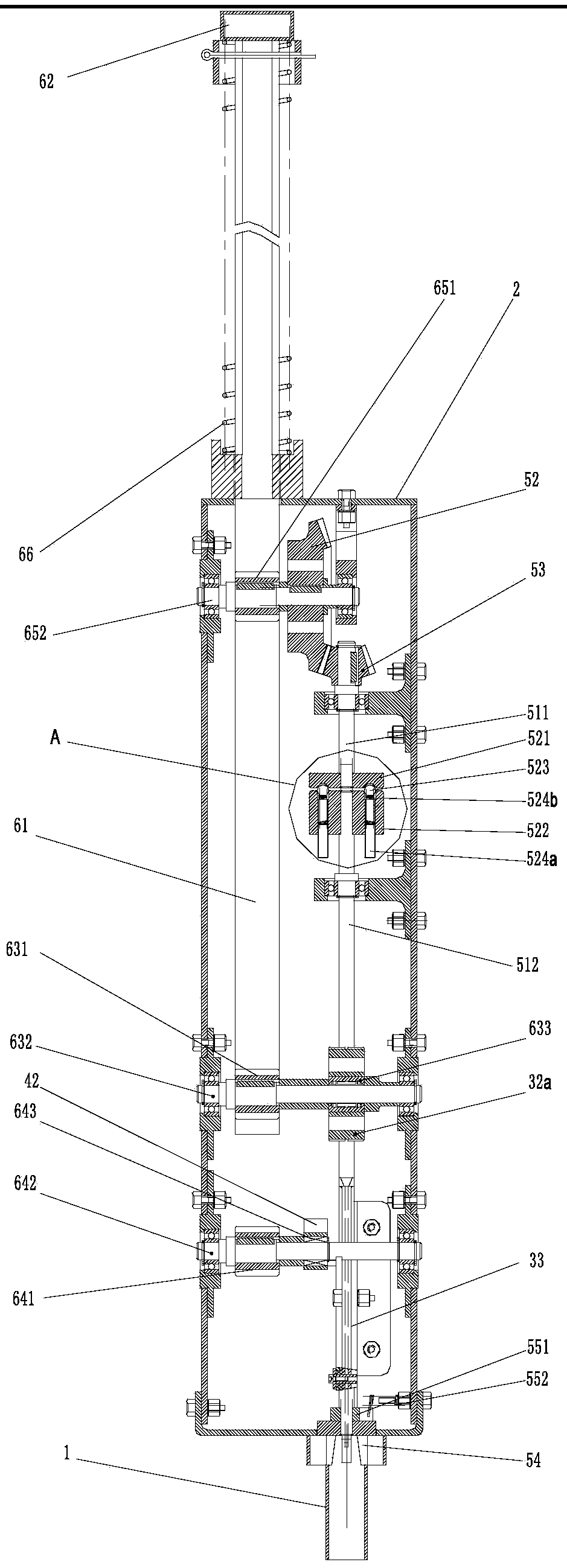

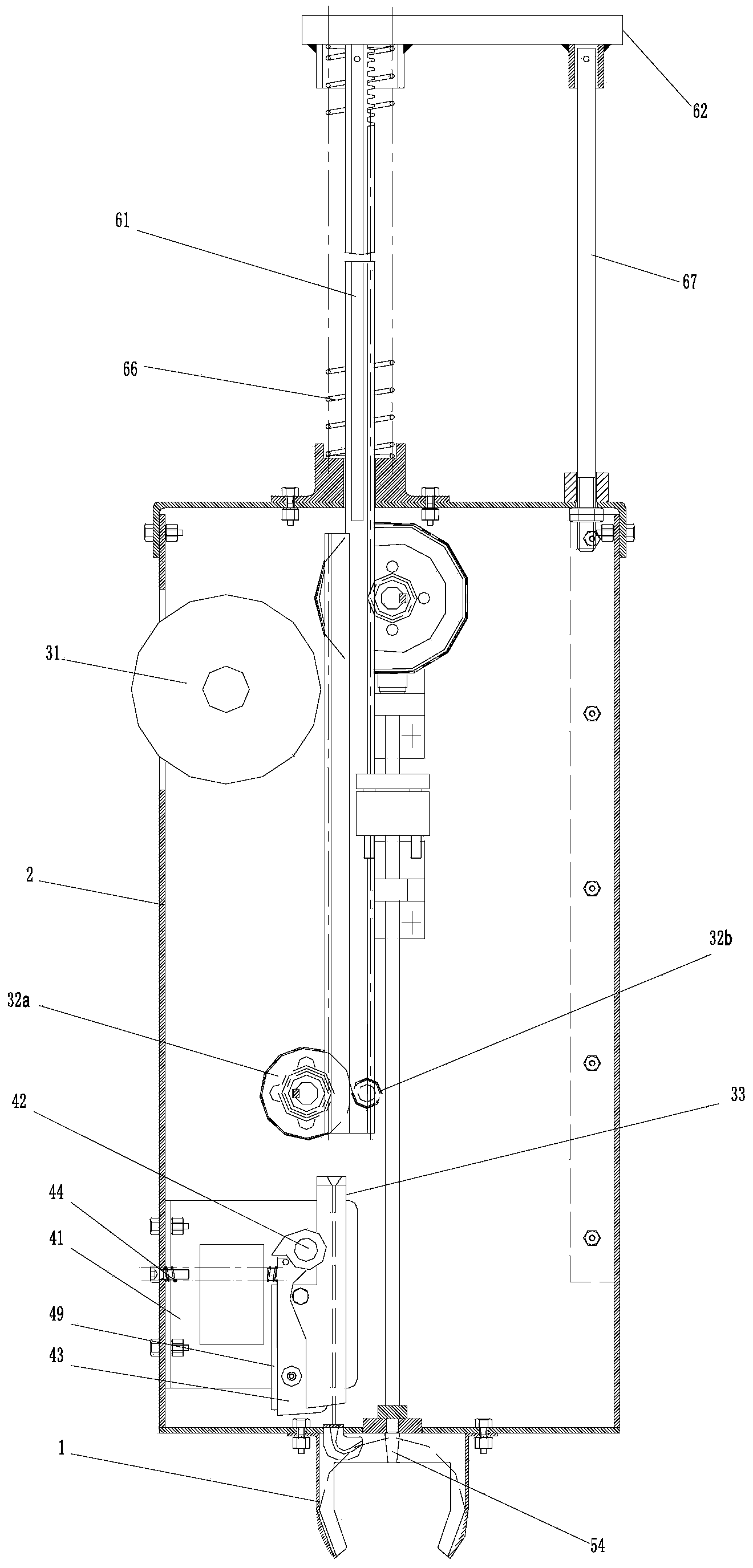

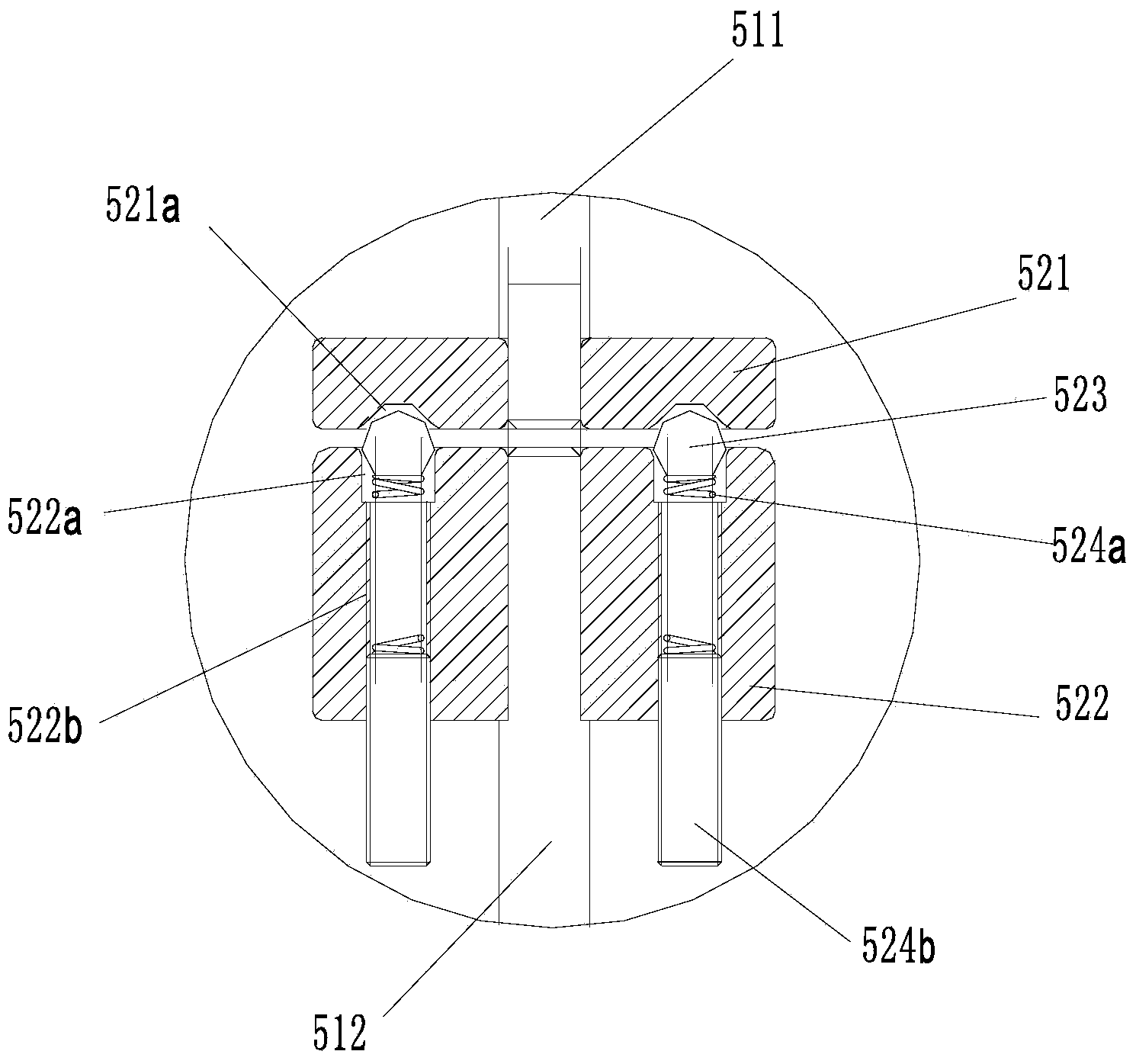

[0021] figure 1 It is the front view of the present invention, figure 2 It is the left view of the present invention, image 3 for figure 1 The enlarged picture at A in the middle is as shown in the figure: the steel bar binding machine of this embodiment includes a machine head 1, a housing 2, a transmission system and a wire feeding system, a wire cutting system and a twisting system fixed inside the housing 2. system, the twisting system includes a twisted shaft, the twisted shaft is a segmented structure and at least includes a driving shaft 511 and a driven shaft 512, and the twisting system also includes a shaft for connecting the driving shaft 511 and the driven shaft. The slipping device of the shaft 512; when the transmission torque between the driving shaft 511 and the driven shaft 512 exceeds the slipping torque of the slipping device, the transmission of the driving shaft 511 and the driven shaft 512 is disengaged; the twisted shaft design At least a two-stage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com