An Ende pulverized coal gasifier with a steam booster

A booster device and gasifier technology, which is applied to the gasification of granular/powdered fuels, the manufacture of combustible gas, and the petroleum industry. The effect of burning out the material, increasing the cycle rate, and reducing the carbon content of the fly ash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

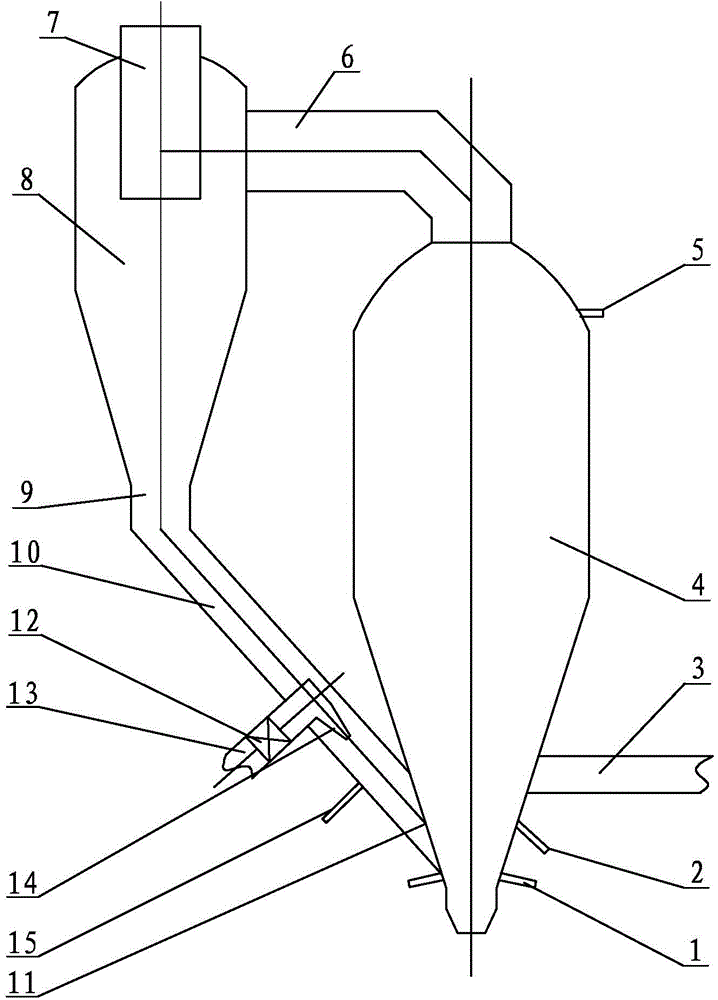

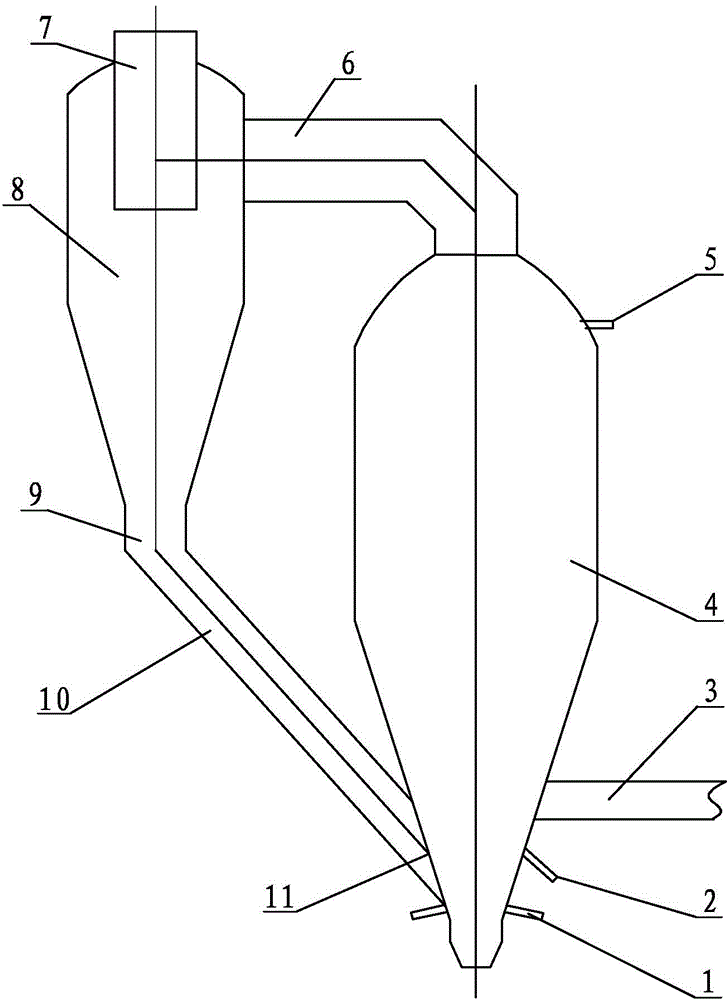

[0023] Specific implementation mode one: combine figure 1 Describe this embodiment, this embodiment includes the pressure measuring point 2 at the bottom of the gasifier, the gasifier 4, the pressure measuring point 5 at the top of the gasifier, the cyclone separator 8, the feeding channel 10, the steam flow regulating valve 12, the steam pipeline 13. The steam nozzle 14 and the pressure measuring point 15 of the descending channel, the pulverized coal inlet 3, the pressure measuring point 2 at the bottom of the gasifier, and the steam and oxygen mixture inlet 1 are arranged on the cone wall of the lower part of the gasifier 4 in order from top to bottom , the top pressure measuring point 5 is set on the top of the gasifier 4, the cyclone separator 8 communicates with the gasifier 4 through the cyclone separator inlet 6, the gas phase outlet 7 is set on the top of the cyclone separator 8, and one end of the feeding channel 10 It communicates with the outlet 9 of the cyclone se...

specific Embodiment approach 2

[0024] Specific implementation mode two: combination figure 1 The present embodiment will be described. The pressure of the high-pressure steam ejected from the steam nozzle 14 of the present embodiment is 0.6 MPa to 1 MPa. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Specific implementation mode three: combination figure 1The present embodiment will be described. The pressure of the high-pressure steam ejected from the steam nozzle 14 of the present embodiment is 0.8 MPa. Other components and connections are the same as those in the second embodiment.

[0026] Specific implementation mode four: combination figure 1 The present embodiment will be described. The flow velocity of the high-pressure steam ejected from the steam nozzle 14 of the present embodiment is 400 m / s to 800 m / s. Other compositions and connections are the same as those in the first, second or third embodiment.

[0027] Specific implementation mode five: combination figure 1 The present embodiment will be described. The flow velocity of the high-pressure steam ejected from the steam nozzle 14 of the present embodiment is 600 m / s. Other compositions and connections are the same as those in Embodiment 4.

[0028] Specific implementation mode six: combination fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com