Process for producing aluminum oxide by using hydrochloric acid method

An alumina and hydrochloric acid process technology, applied in the chemical industry, inorganic chemistry, aluminum compounds, etc., can solve the problems of high decomposition heat consumption, equipment corrosion and wear, high cost, avoid the accumulation of impurities, increase economic benefits, and solve the problem of wear and tear Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]The low-grade bauxite is crushed and ground, and the output particle size of the ground is 75 μm. The grinding pulp is mixed with 31% hydrochloric acid and enters the dissolution system. The dissolution temperature is 120°C, the dissolution time is 2 hours, and the dissolution rate of aluminum reaches more than 95%. The dissolved ore pulp is separated and washed, and discharged to the acid slag yard. The separated crude liquid is fine-filtered with a pre-coated vertical leaf filter, and the obtained aluminum chloride semen contains 10 mg / L of floating matter. Concentrate the aluminum chloride semen to a concentration of 32% aluminum chloride by using a three-effect down-flow falling film evaporator, and then enter the acid analysis system. The acid analysis temperature is controlled at 45°C, and the crystallization residence time is 1 hour to obtain aluminum chloride hexahydrate with an average particle size of 0.5 mm and a purity of >99.7%, and the purity of alumina aft...

Embodiment 2

[0029] High-alumina circulating fluidized bed fly ash is mixed with 29% hydrochloric acid into the dissolution system, and the hydrochloric acid is mixed according to 95% of the theoretical required acid amount. The dissolution process parameters are: dissolution temperature 180°C, dissolution time 2.5h. At this time, the dissolution rate of aluminum reaches more than 90%, and the dissolution rate of iron is close to 100%. The dissolved ore pulp is separated and washed, and discharged to the acid slag stockpile. The separated crude liquid is fine-filtered with a pre-coated vertical leaf filter, and the obtained aluminum chloride semen has a float content of 5 mg / L. The aluminum chloride semen is concentrated to a concentration of 30% aluminum chloride by a four-effect down-flow falling film evaporator, and then enters the acid analysis system. The acid analysis temperature is controlled at 55°C, and the crystallization residence time is 0.5h to obtain aluminum chloride hexahy...

Embodiment 3

[0031] Aluminum hydroxide and 36% hydrochloric acid are mixed into the dissolution system, the dissolution temperature is 80°C, the dissolution time is 1h, and the dissolution rate of aluminum reaches 100%. After dissolution, aluminum chloride semen is obtained, the concentration of which is about 27%, and the content of suspended matter is <1mg / L. Aluminum chloride crystallizes into the acid analysis system. The acid analysis temperature is controlled at 15°C to obtain colloidal aluminum chloride hexahydrate with a purity of 99.999%, and ultrafine alumina with a purity of 99.997% after calcination.

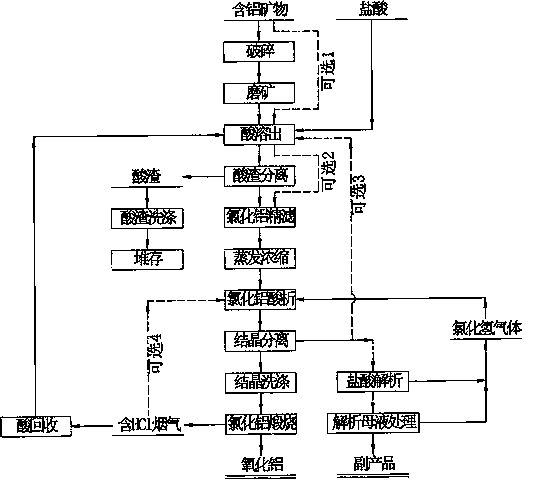

[0032] Provided in the present invention such as figure 1 In the shown a kind of technology that adopts hydrochloric acid method to produce alumina,

[0033] ——The acid dissolution system adopts a semi-continuous or continuous dissolution process, and the preferred equipment is an enamel dissolution tank and a PTFE-lined dissolution tank; wherein, the process parameters of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com