Tire self-inspection system and tire self-inspection method

A self-inspection system and tire technology, applied in tire measurement, vehicle parts, tire parts, etc., can solve problems such as danger, lack of knowledge of tire inspection, and not knowing how to identify tires, etc., to achieve optimal accuracy and comprehensiveness , Improve the actual use value, eliminate the effect of vehicle safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to have a further understanding of the purpose, structure, features, and functions of the present invention, the following detailed descriptions are provided in conjunction with the embodiments.

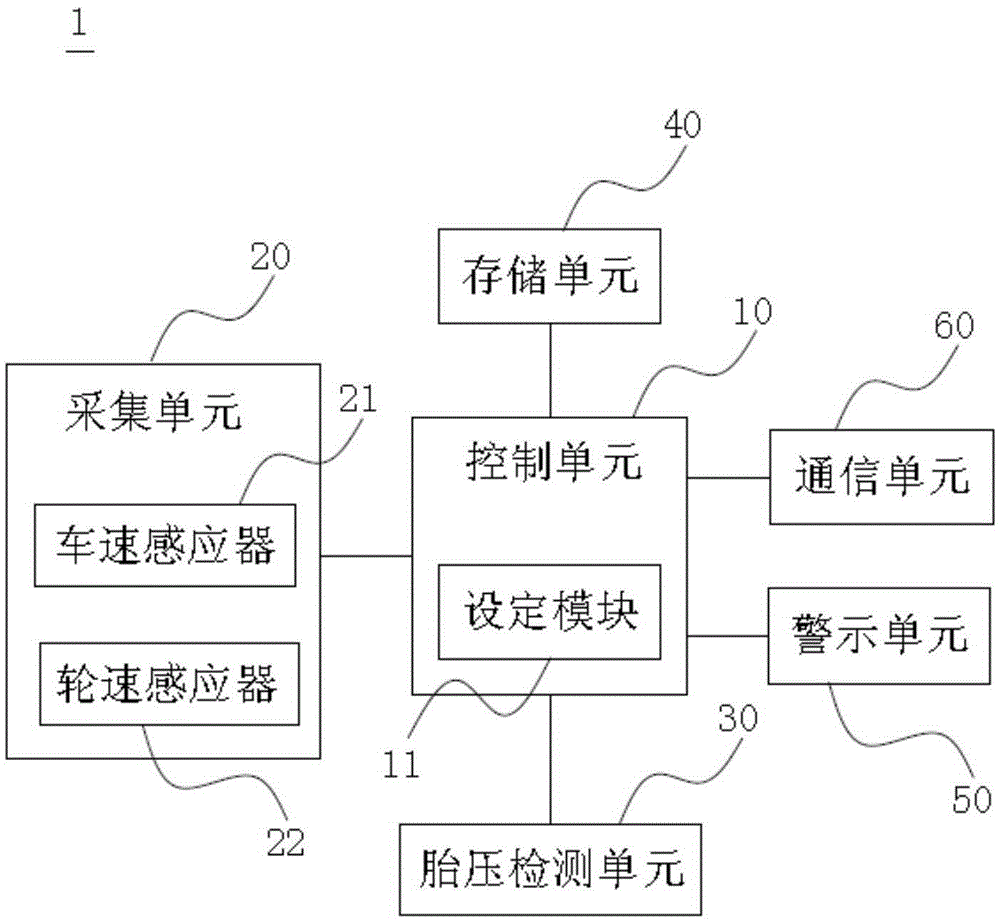

[0028] Please refer to figure 1 , is a system architecture diagram of the tire self-inspection system of the present invention. In the present invention, the tire self-inspection system 1 is applied to the vehicle to perform self-inspection on the tires of each wheel, which mainly includes a control unit 10 and an acquisition unit 20 connected thereto, wherein the control unit 10 is mainly used for various data Calculation processing, for example, it can be a vehicle-mounted computer or a microprocessor installed in a traffic monitoring device in the car. In a broad sense, as long as the module that can realize data processing can be understood as the control unit 10 in the present invention; and The collection unit 20 is used for collecting various data, and the abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com