Reinforced aluminum alloy hub with antiskid bolt holes

A technology for aluminum alloy wheels and bolt holes, which is applied in the direction of wheels, transportation and packaging, and vehicle parts, can solve the problems of limited strength of wheel bolt holes and loose bolts, so as to improve driving safety performance, prolong service life, and prevent slipping and loosening good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

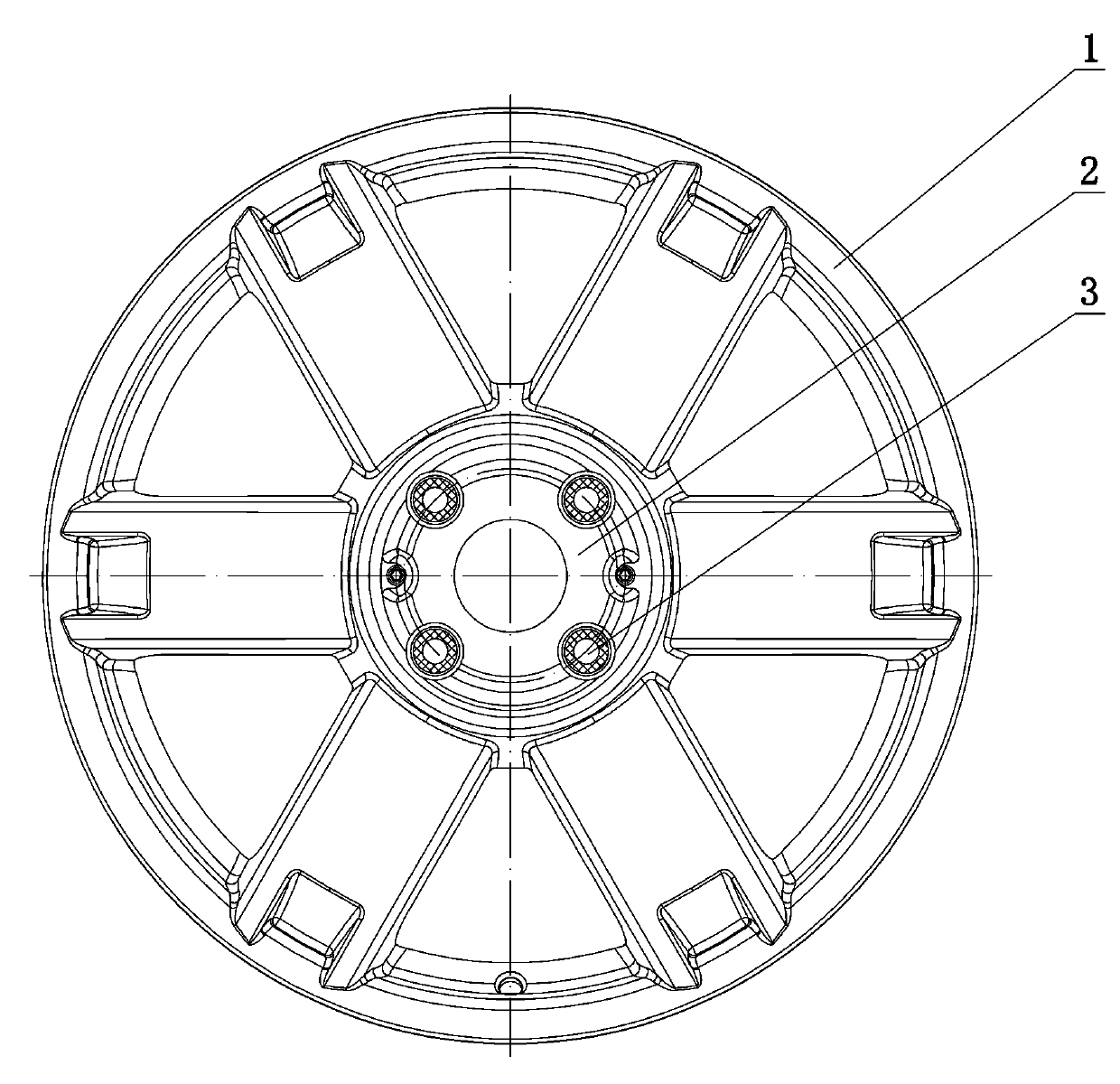

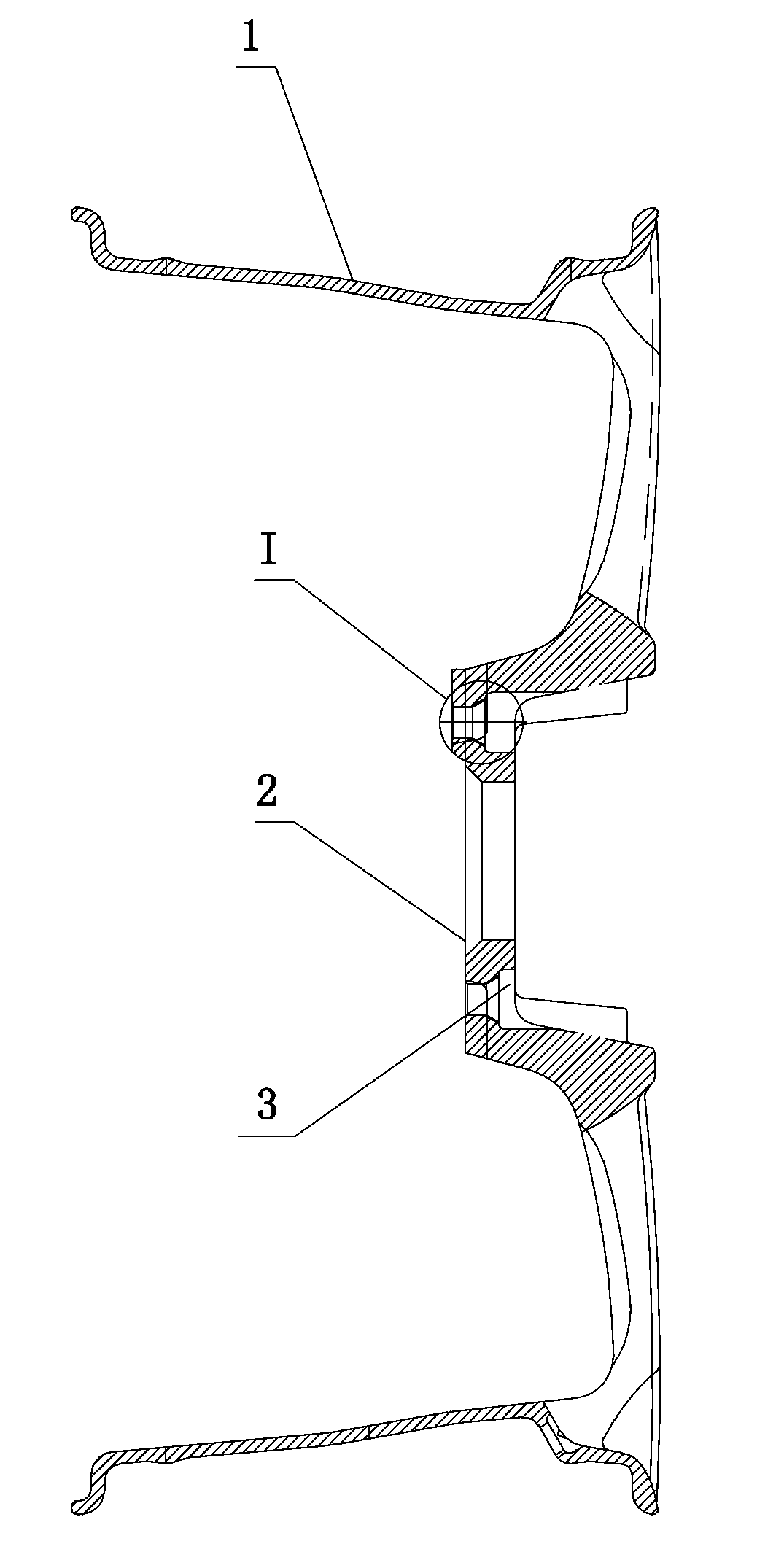

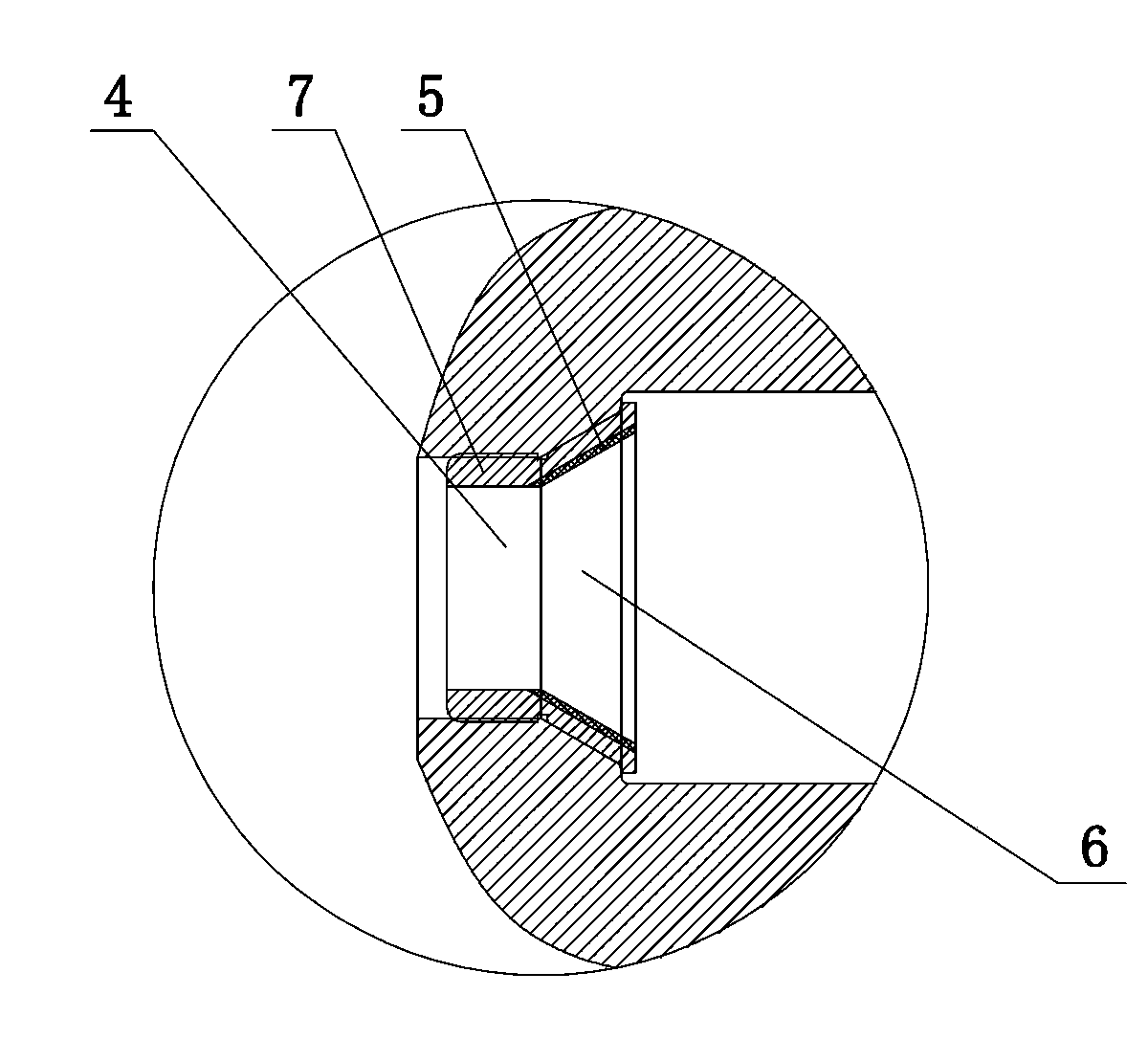

[0012] see figure 1 , 2 , 3, the present invention has hub body 1, has four installation holes 3 on the installation hub 2 of hub body 1 (can also be 5, 6 or even more installation holes according to different specifications), especially: in A steel sleeve 7 is housed in each mounting hole 3, and a bolt hole is arranged in the steel sleeve 7. The bolt hole is composed of a cylindrical hole section 4 and a tapered hole section 6, and anti-skid rollers are rolled on the surface of the tapered hole of the bolt hole. spend 5.

[0013] The anti-slip knurling 5 on the surface of the tapered hole of the bolt hole of the steel sleeve described in this embodiment is a textured knurling, and the knurling modulus is 0.8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com