High-uniformity damping rotating nozzle

A technology of rotating nozzles and uniformity, which is applied in the direction of spraying devices, spraying devices, spraying devices with movable outlets, etc. It can solve the problems of inconvenient adjustment and closing, complex structure of rotating nozzles, and inability to improve irrigation uniformity. , to achieve the effect of easy cleaning and maintenance, good atomization effect and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

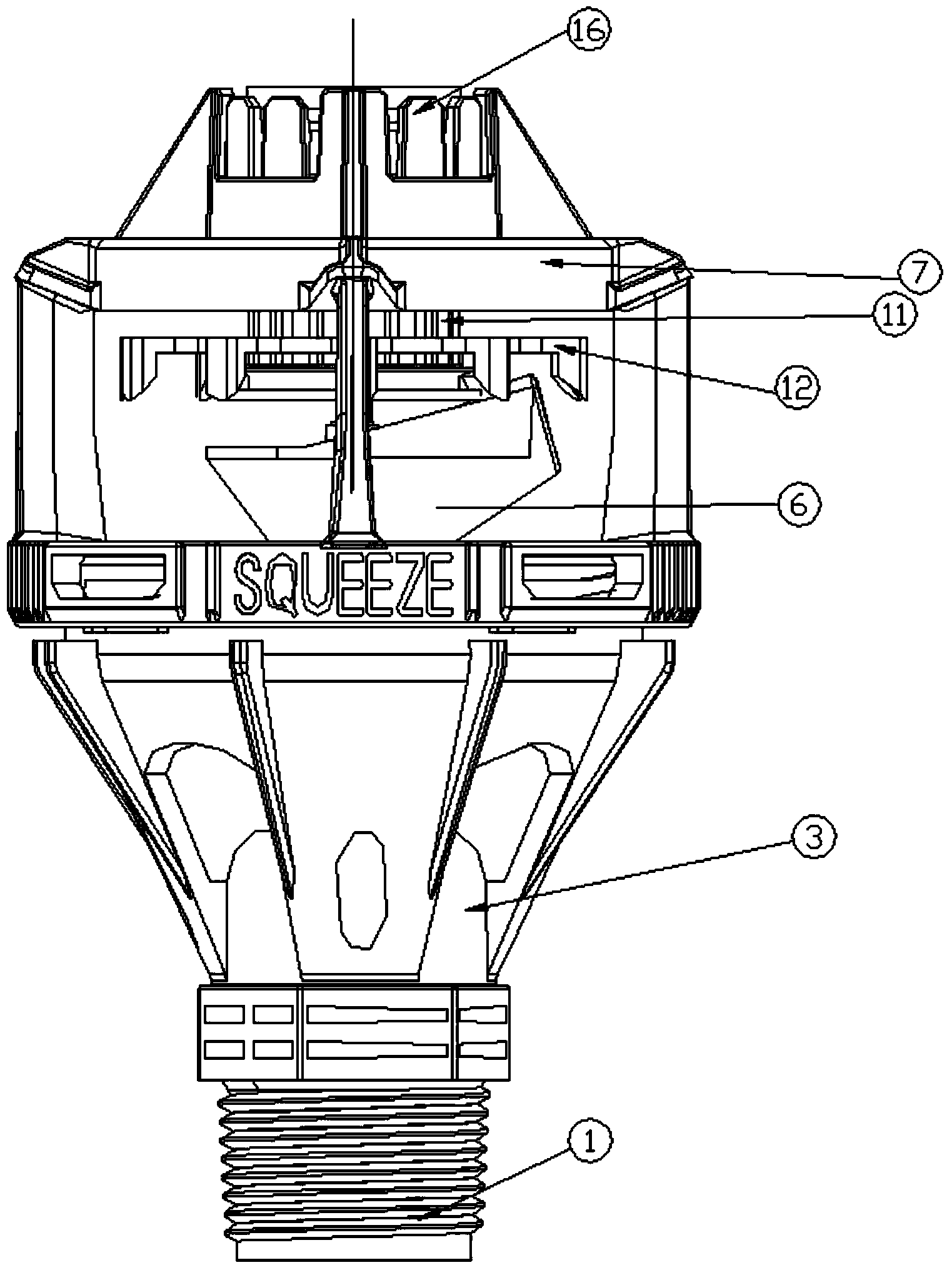

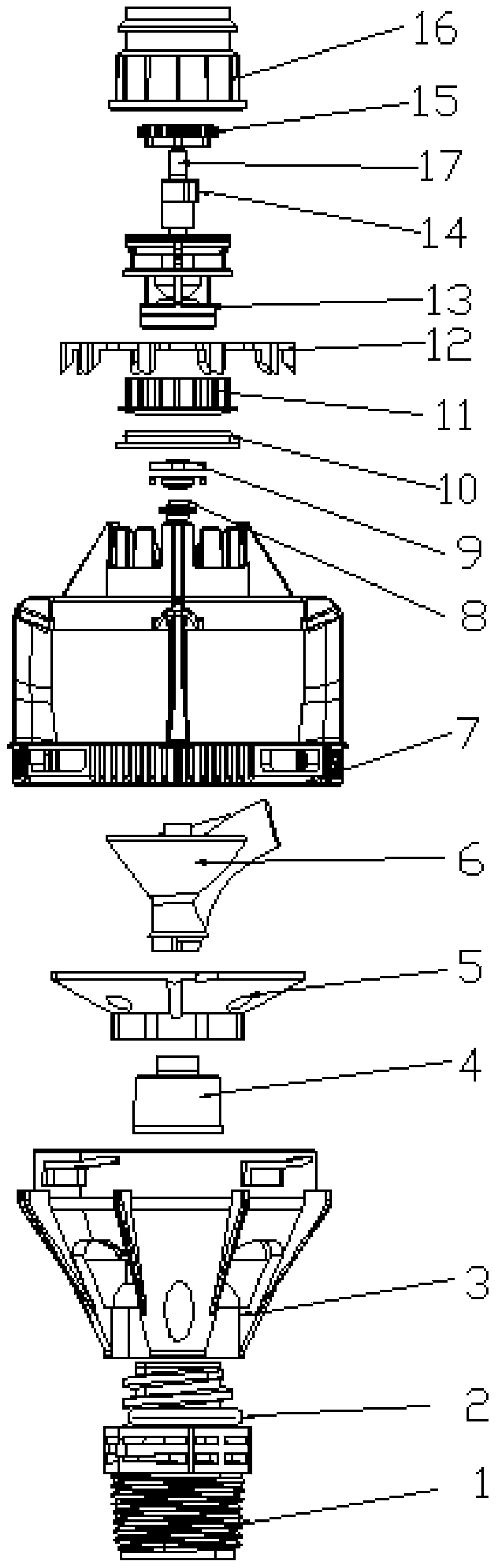

[0048] refer to figure 1 , figure 2 with image 3 As shown, a high-uniformity damping rotary spray head includes a spray head housing, an outer wire joint 1, a nozzle 4, and a rotating assembly and a water spray assembly that are all arranged in the spray head housing.

[0049] refer to Figure 8 , Figure 9 , Figure 10 with Figure 11 As shown, the nozzle housing includes a nozzle upper cover 7 and a nozzle lower cover 3, both of which are detachably connected.

[0050] The outer wire joint 1 is threadedly connected to the lower end of the nozzle lower cover 3, and the connection between the outer wire joint 1 and the nozzle lower cover 3 is equipped with two first sealing rings 2, which act as a water seal. The outer wire joint 1 is connected to an external pipeline for Ingress of water.

[0051] The inner wall of the lower nozzle c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com