Surrounding type blowing dust removal device

An ash cleaning device and a wrap-around technology, which are used in the separation of dispersed particles, chemical instruments and methods, and filtration of dispersed particles, etc., can solve problems such as unfavorable work efficiency, loss, pollution and purification of gas, and achieve ingenious and reasonable structural design. The effect of tightness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

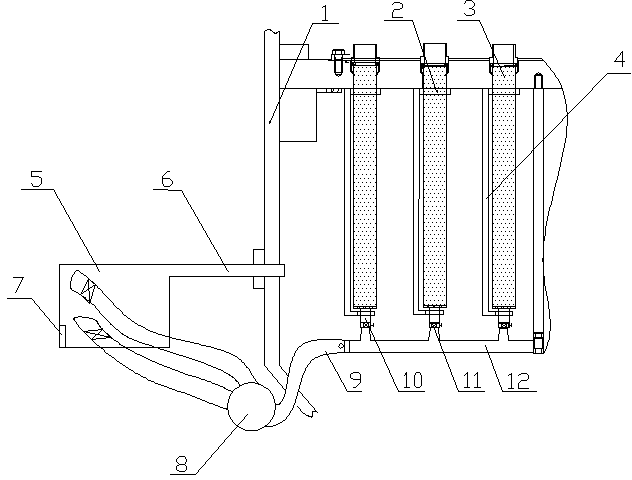

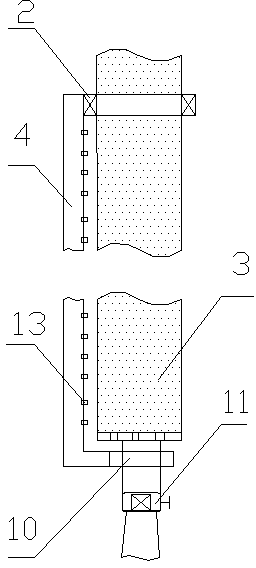

[0028] Embodiment one: if figure 1 , figure 2 and image 3 Shown, a kind of encircling blowing soot cleaning device, it comprises blowing gas conveying pipe 9, control valve 11, swivel joint 10 and blowing pipe 4, and described blowing pipe 4 is provided with several nozzles 13, and described control valve 11 The rotary joint 10 is arranged at the lower part of the filter element 3 of the dust collector.

[0029] The blowing pipe 4 is L-shaped, the upper part of the blowing pipe 4 is connected with the upper part of the filter core 3 of the dust collector through the bearing 2 , and the lower part is connected with the control valve 11 through the rotary joint 10 .

[0030] The filter element 3 is a stainless steel filter element.

[0031] The blowing gas delivery pipe 9 is connected to the cooling device 5, and the cooling device 5 is connected to the dust-laden gas inlet pipe 6 of the dust collector.

[0032] The blowing gas delivery pipe 9 is provided with a pressure ...

specific Embodiment 2

[0038] The difference from Embodiment 1 is that the cooling device 5 is an air cooler.

specific Embodiment 3

[0039] The difference from Embodiment 1 or 2 is that: the pressure raising device 8 is an air compressor.

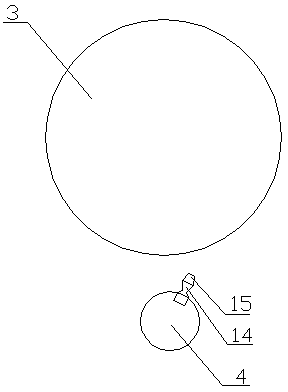

[0040] In order to better describe this device, its mechanism principle is as follows: the present invention includes a series-connected blowing gas delivery pipe, a control valve, a rotary joint and a blowing pipe, and the blowing gas delivery pipe is provided with a pressure raising device, which can realize The blowing of low-temperature and high-pressure gas makes the stainless steel filter core shrink and remove dust. The lower part of the blowing pipe is connected to the rotary joint, and the rotary joint is connected to the control valve, and the angle between the opening direction of the nozzle and the diameter direction of the filter core is cleverly used. The characteristics make it possible not only to blow the gas on the surface of the filter element, but also to realize its high-speed rotation around the filter element, so that the cooling gas can quickly coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com