Dimming component and heat resisting sheet combined assembling device for automobile front fog lamp

A combined assembly, front fog lamp technology, applied in lighting devices, fixed lighting devices, components of lighting devices, etc., can solve the problems of reducing assembly accuracy, high labor intensity, increasing assembly time, etc., to ensure assembly consistency, Reasonable and compact structure, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

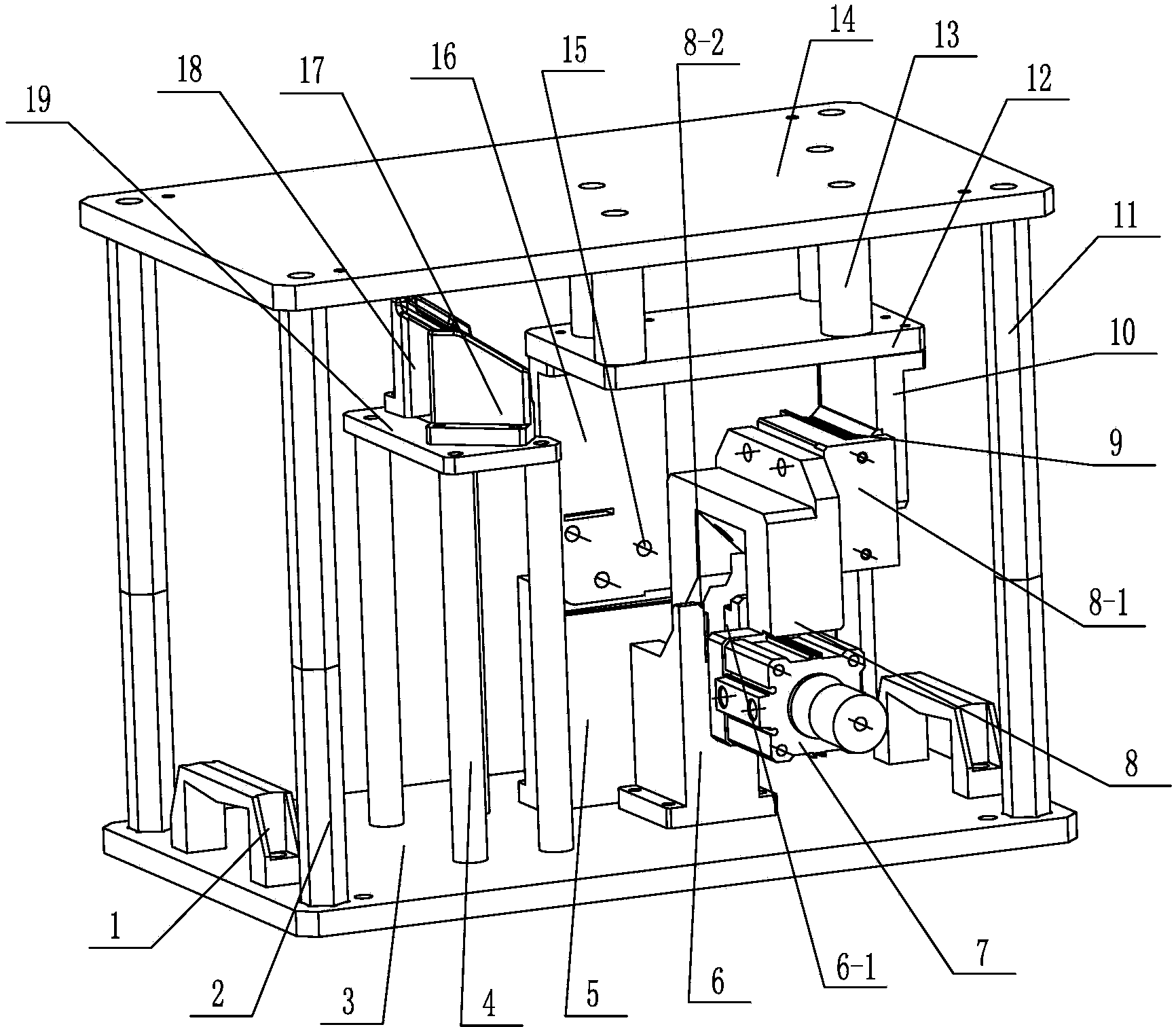

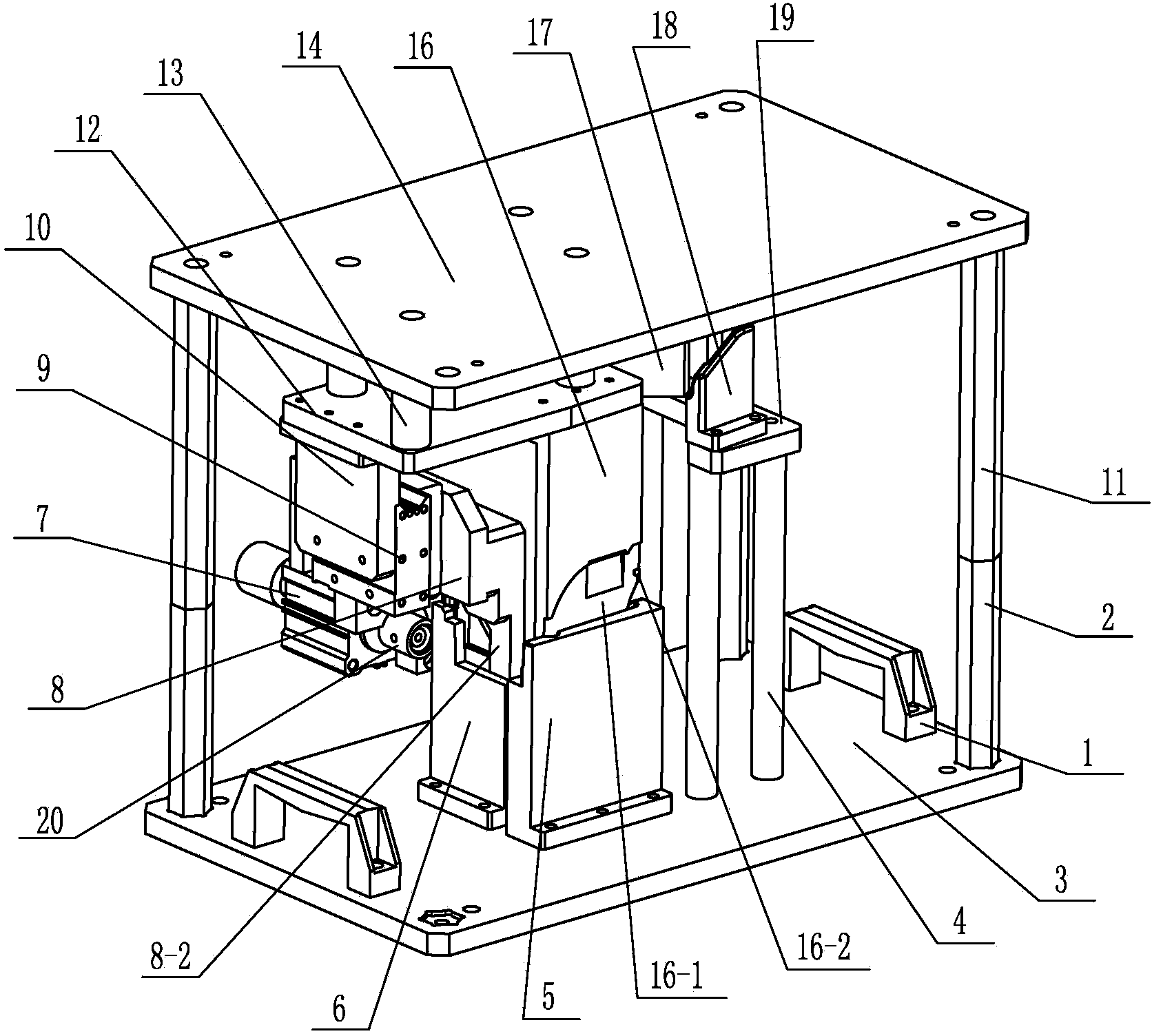

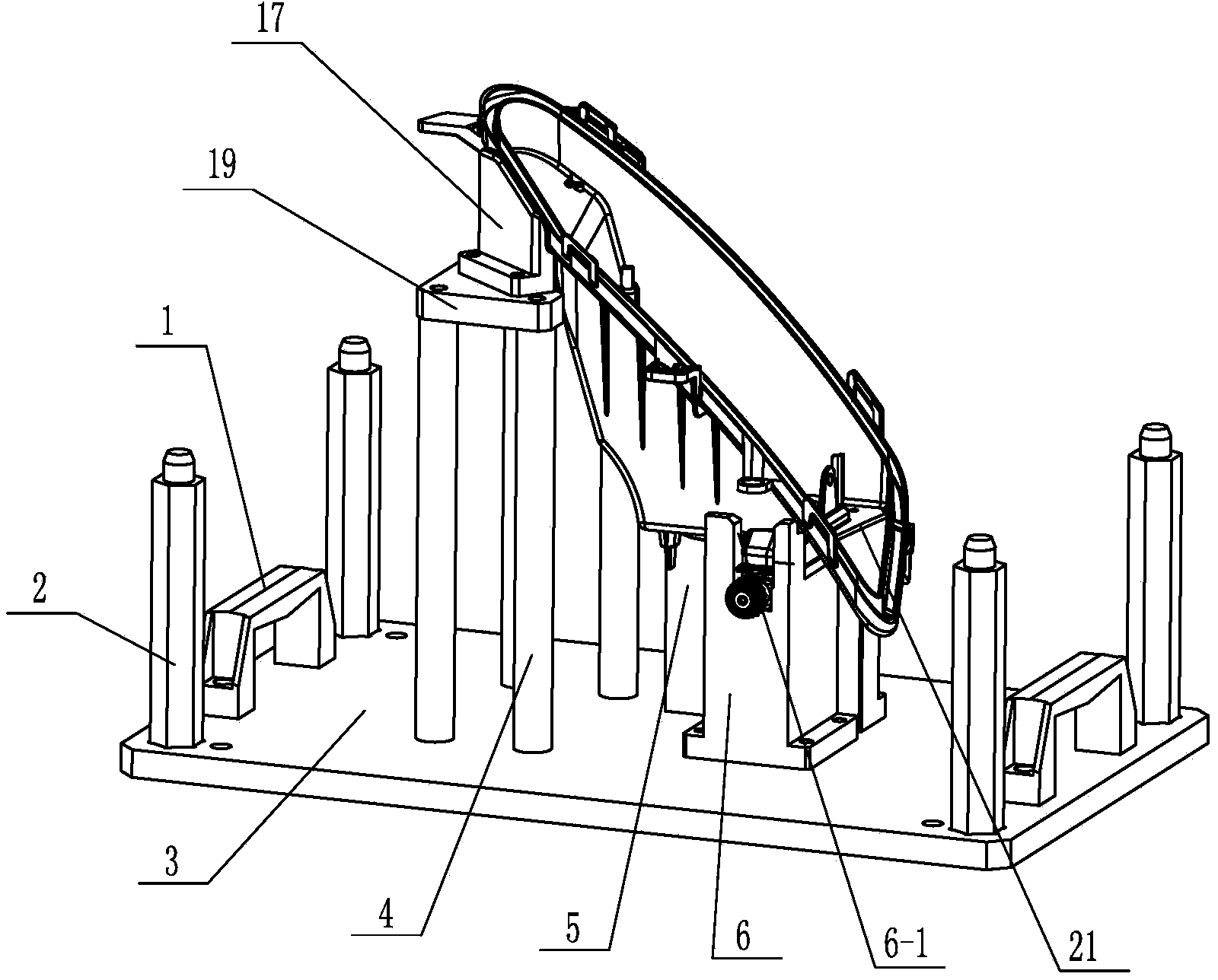

[0019] See Figure 1~4 As shown, the dimming assembly of the automobile front fog lamp and the combined assembly device of the heat shield of the present invention include an upper mold assembly and a lower mold assembly, and the upper mold assembly and the lower mold assembly can be installed on the press, The lower mold assembly is installed on the workbench, the upper mold assembly is connected with the working cylinder of the press, and the upper mold assembly is driven to move up and down by the action of the working cylinder. When the upper mold assembly moves up, the lamp holder 21 Place it on each limit seat of the lower mold assembly, and place each part to be assembled, and connect with the lower mold assembly when moving down, and assemble the dimming assembly.

[0020] See Figure 1~3 As shown, the lower mold assembly of the present invention includes a base plate 3, at least two lower guide columns 2 installed on the upper periphery of the base plate 3, a first s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com