A high-efficiency motor vehicle power generation system

A technology for power generation systems and motor vehicles, which is applied in electric braking systems, electric vehicles, machines/engines, etc. It can solve the problems of unable to meet the power requirements of automobiles, simple structure, and impracticality, so as to improve the shock absorbing effect and set up reasonably , the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

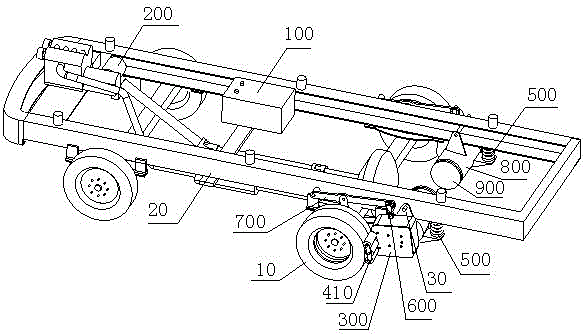

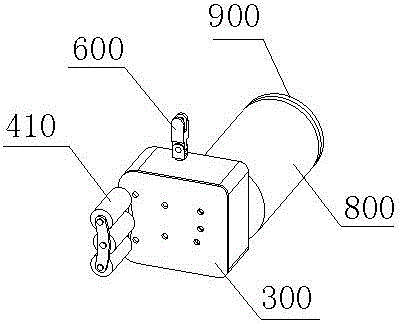

[0025] This embodiment discloses a high-efficiency motor vehicle power generation system, such as figure 1 As shown, it includes a battery 100 , a drive motor 200 connected to the battery 100 and providing power for the motor vehicle, a first generator, a transmission gearbox 300 and a power structure. In this example, see figure 2 , the power structure is a power generating wheel 410, the power generating wheel 410 is arranged close to the wheel 10 of the motor vehicle, and a first gear set connected to the power generating wheel 410 is arranged inside the transmission gearbox 300, and the first gear set is connected through a single-phase bearing The power shaft of the first generator, the first generator is electrically connected to the battery 100: the power generating wheel 410 is driven to rotate by the vehicle wheel 10, and the first generator is driven to rotate through the first gear set. The power shaft of the first generator is connected with an inertial flywheel ...

Embodiment 2

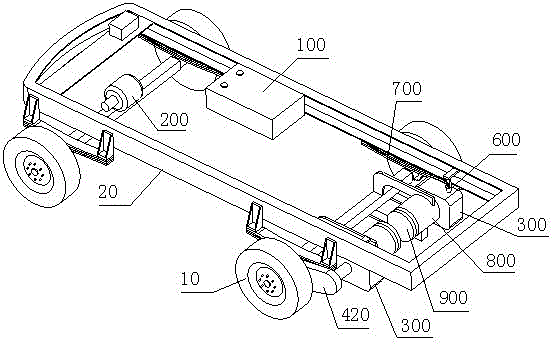

[0040] The structure of the high-efficiency motor vehicle power generation system disclosed in this embodiment is basically the same as that in Embodiment 1. The difference is that the power structure in this embodiment is a transmission chain (the transmission chain is installed inside the chain protection cover 420), and the transmission chains are respectively connected. Motor vehicle axle and first gear set. At the same time, the gear box 300 is arranged inside the vehicle frame 20 .

[0041] This high-efficiency motor vehicle power generation system in this embodiment is suitable for bridge vehicles.

[0042] In practical applications, the first generator, the second generator and the metamorphic wave box can also be integrated to further reduce the structure of the power generation system. This power generation structure is suitable for installation on motorcycles.

[0043] The effect that the high-efficiency motor vehicle power generation system in this embodiment is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com