Method for preparing environmentally friendly material by sludge low-temperature carbonization

An environmentally friendly material and low-temperature carbonization technology, applied in chemical instruments and methods, sludge treatment, pyrolysis treatment of sludge, etc., can solve the problems of high investment and operation costs, incomplete harmlessness, and difficult operations, and achieve free Eliminate environmental and human health hazards, reduce high heat source fuel costs, and have no secondary pollution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the embodiments in the accompanying drawings, but this does not constitute any limitation to the present invention.

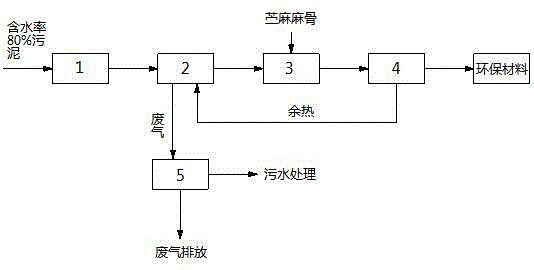

[0017] refer to figure 1 As shown, the method for preparing environmentally friendly materials by low-temperature carbonization of sludge in the present invention includes the following steps: 1) Pulverization: send the sludge (with a moisture content of about 80%) dehydrated by the sludge dehydrator into the pulverizer 1, Stirring and crushing, the crushing time is 15~20min; 2) Drying: After the sludge is crushed, it is sent to the dryer 2 for low-temperature drying, the temperature is controlled at 90~100°C, and the drying time is 15~20min; 3) Mixing: sludge drying Then enter the mixer 3, add an appropriate amount of ramie bone to mix and stir, and the stirring time is 5-8 minutes to obtain a mixture of sludge and ramie bone with a moisture content of 50%; 4) Carbonizat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com