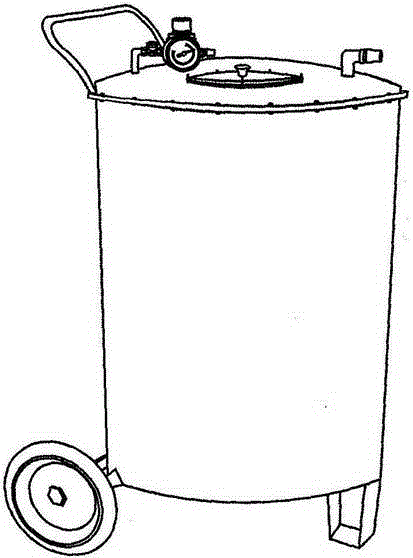

A car wash foam machine

A technology for foaming machine and car washing, applied in the field of car washing foaming machine, can solve the problems that the foaming machine cannot produce foam normally, cannot mix car washing liquid and water, increase natural environment pollution, etc., and achieves compact structure design, convenient realization, and pressure resistance. good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

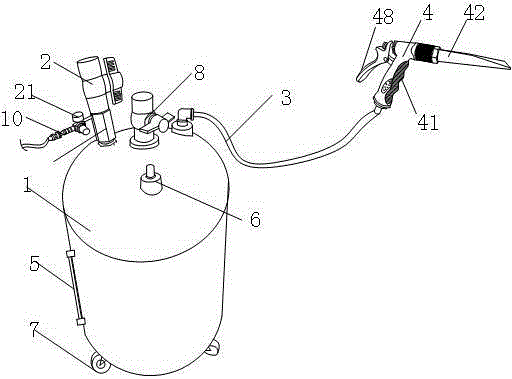

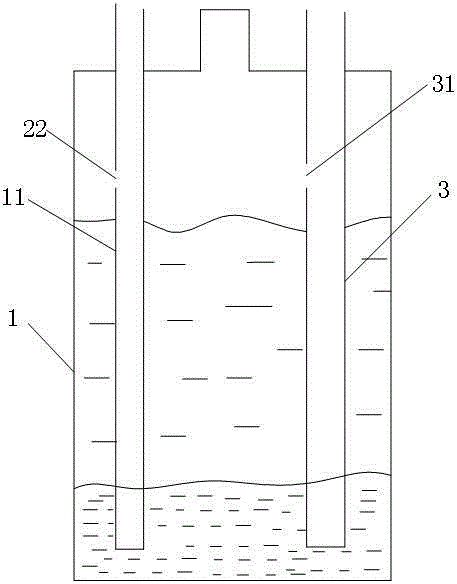

[0036] Such as figure 2 As shown, this embodiment provides a new type of energy-saving and environment-friendly foam machine for car washing, which mainly includes five components such as a mixing tank 1, an air pressure quantitative liquid feeding device, a liquid outlet pipe 3, a foam spray gun 4 and a water feeding pipe 8. Wherein, mixing tank 1 is the mixing equipment of foam machine, and tap water and car washing liquid are mixed in mixing tank, and the uniformity of its mixing directly affects the foaming amount of foam and the addition amount of car washing liquid. Usually, adding tap water and car wash liquid to the mixing tank is completed by adding water pipes. The liquid addition step is to add tap water first, and then add car wash liquid. Since the specific gravity of car wash liquid is greater than that of tap water, after adding car wash liquid, It will sink to the bottom of the mixing tank, so the tap water and car wash liquid present a layered structure of up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com