Solid-liquid mixture filter device

A kind of technology of solid-liquid mixture and filtration device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

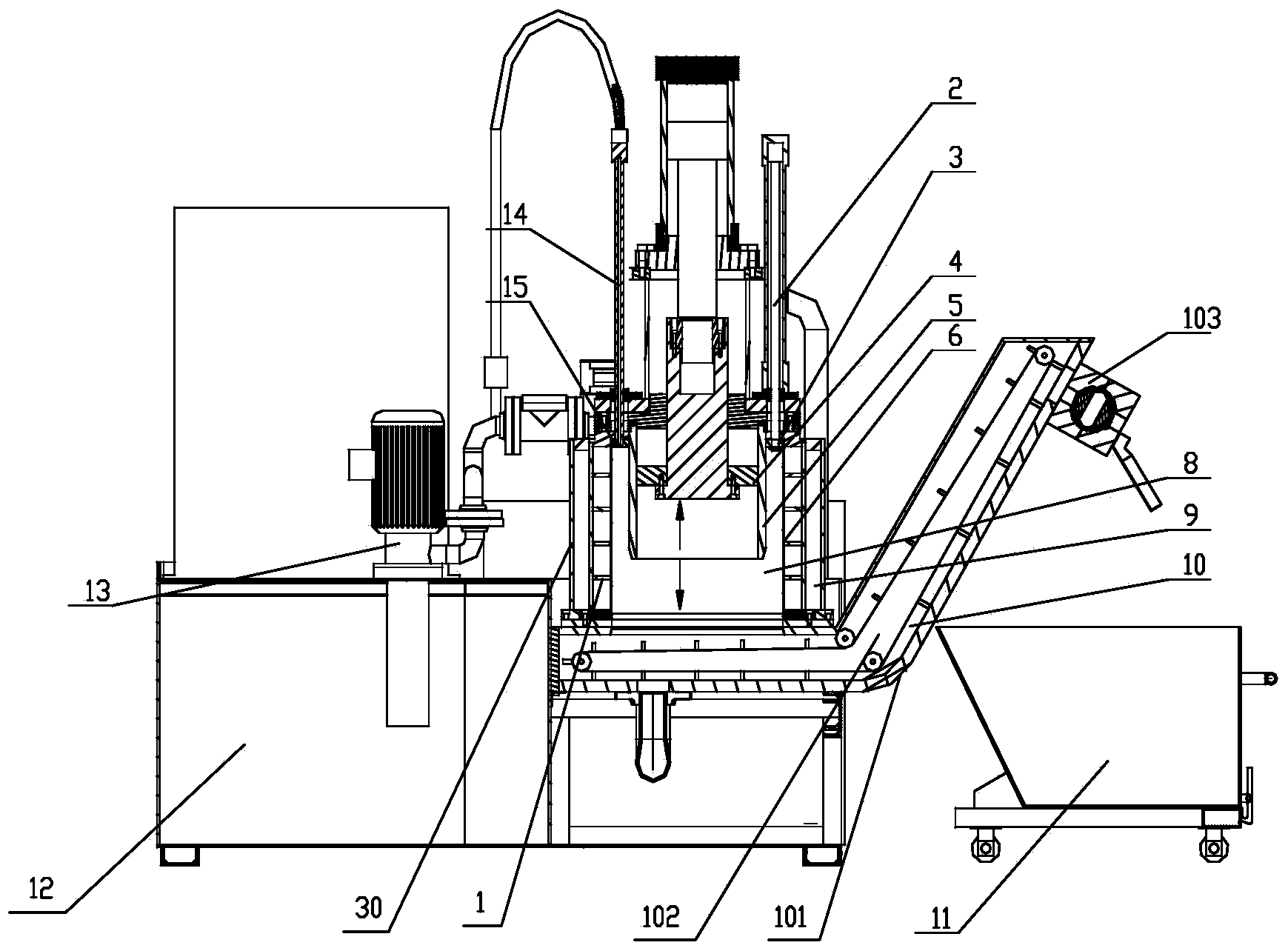

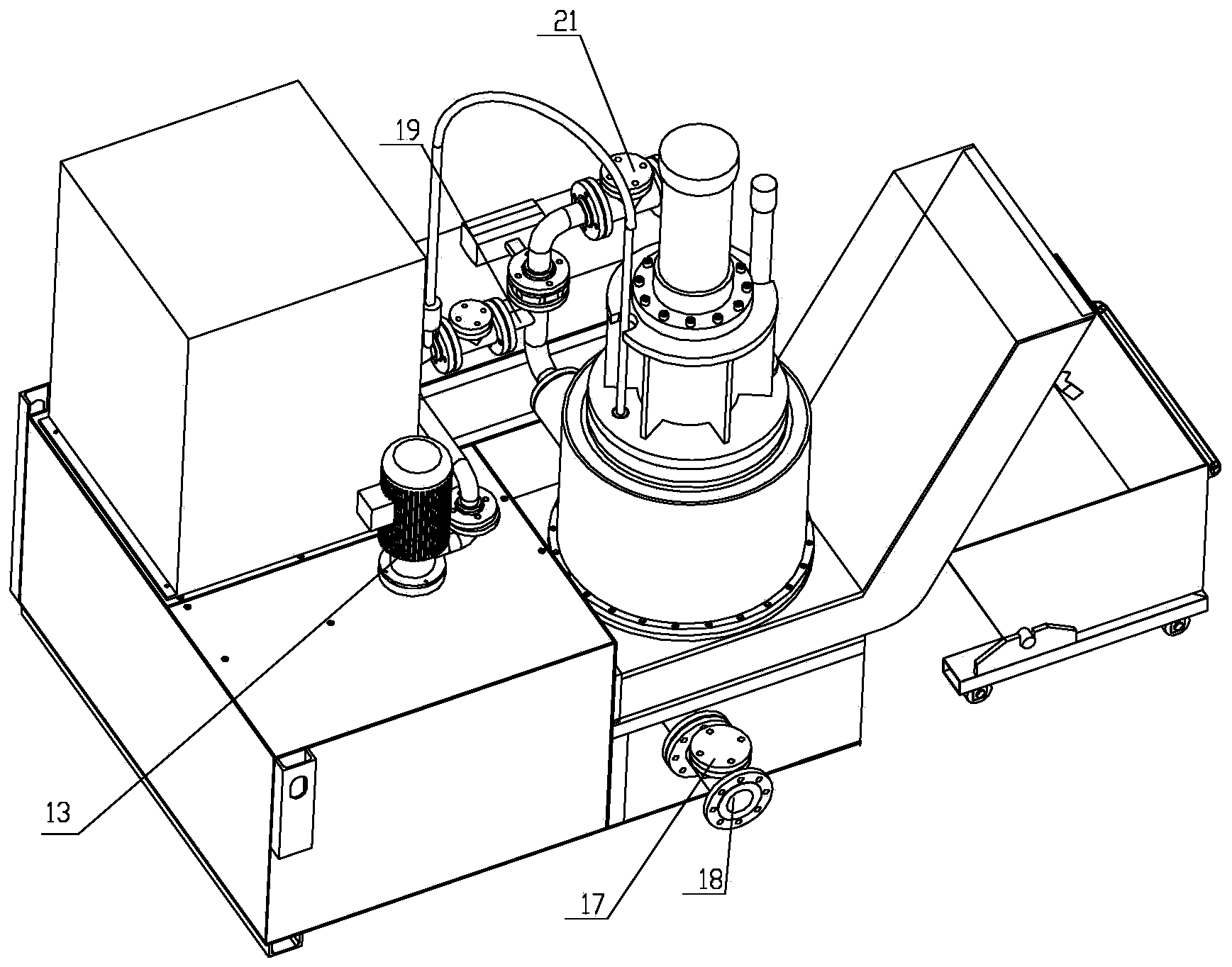

[0056] See attached figure 1 , 2 , a solid-liquid mixture filtering device, comprising a tank 30, a cylinder liner 5, a piston 4, a filter medium 6, and a solid discharge device 10;

[0057] The tank 30 is a hollow sealed cylindrical structure, and the bottom communicates with the solid discharge device 10; a filter medium 6 is arranged in the tank 30, and the filter medium 6 is fixed on the support frame 1 according to the horizontal direction of the tank 30. The cross-sectional shape surrounds a cylinder, which separates the inner space of the tank 30 into two parts: the filter cavity 8 and the clean liquid cavity 9;

[0058] The filter chamber 8 is the space surrounded by the inner wall of the cylinder formed by the filter medium 6, and the clean liquid chamber 9 is the space between the outer wall of the cylinder formed by the filter medium 6 and the inner wall of the tank 30;

[0059] The filter chamber 8 and the clean liquid chamber 9 are communicated through filter ho...

Embodiment 2

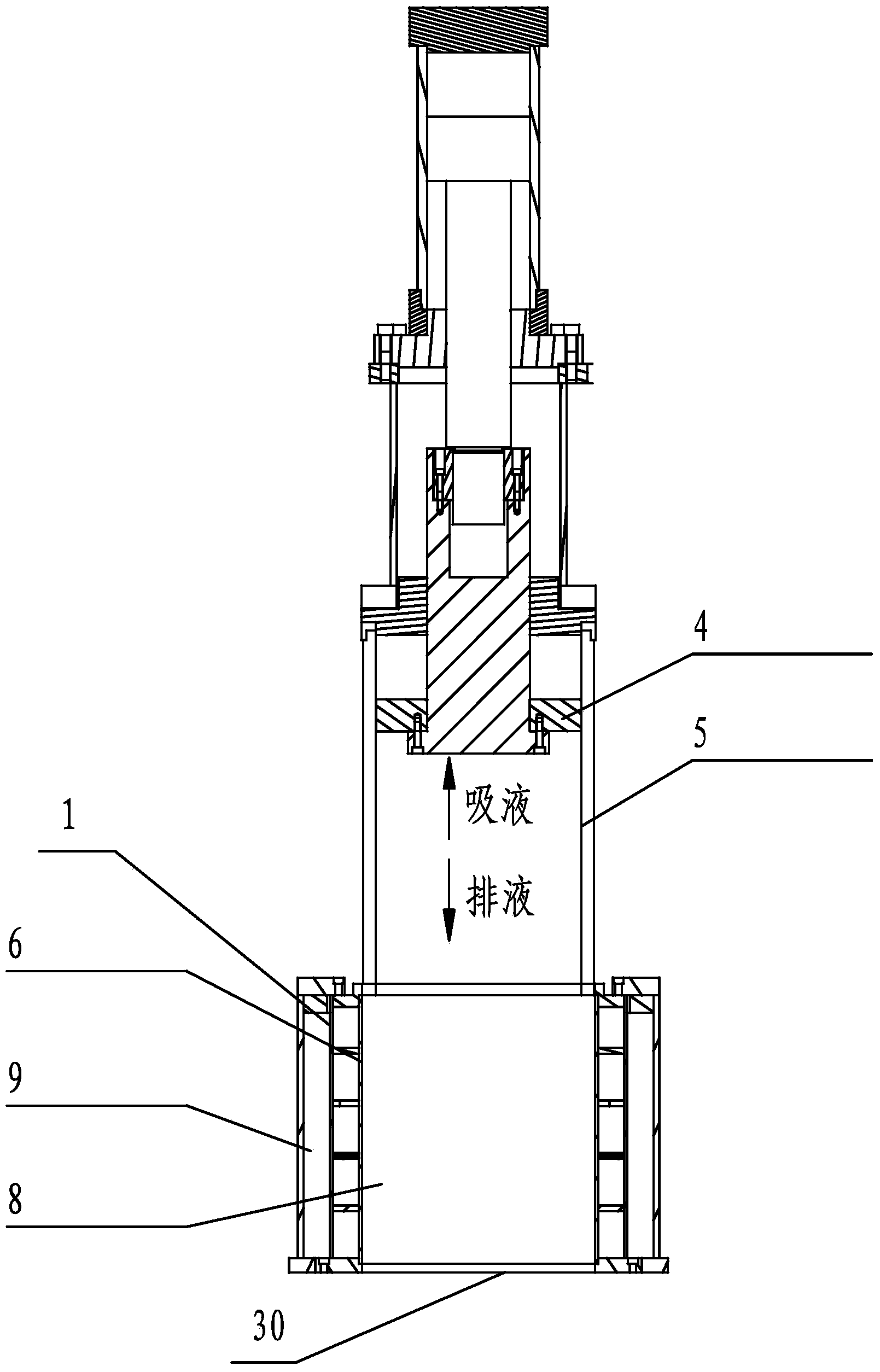

[0073] The difference between this embodiment 2 and embodiment 1 is that the connection and positional relationship between the cylinder liner 5 and the filter cavity 8 in the tank 30 are different;

[0074] See attached image 3 , in this embodiment, the cylinder liner 5 and the filter chamber 8 are coaxially installed on the upper end surface of the filter chamber 8 and communicate with the filter chamber 8 .

Embodiment 3

[0076] The difference between this embodiment 3 and embodiment 2 is that the connection and positional relationship between the cylinder liner 5 and the filter cavity 8 in the tank 30 are different;

[0077] See attached Figure 4 In this embodiment, the 5 sets of cylinders are connected in series on the liquid inlet pipe 18 to communicate with the filter cavity 8; on the liquid inlet pipe 18, there is a The check valve 26 between the filter chambers 8, the cylinder liner 5 is located between the check valve 26 and the liquid inlet check valve 17.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com