A seed metering device for an air-suction precision seeder

A seeder and metering device technology, applied in the field of agricultural machinery, can solve problems such as complex structure, no ridge formation, and difficulty in realizing standardized operations, and achieve the effect of compact structure and low power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit this invention.

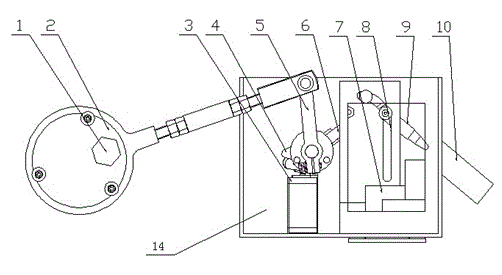

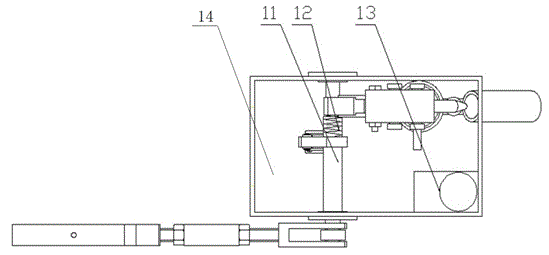

[0014] please see figure 1 , figure 2 , the technical solution adopted in the present invention is: a seed metering device of an air-suction precision seeder, which is arranged on the traveling mechanism, and is characterized in that it includes a driving shaft 1, an eccentric wheel mechanism 2, a mechanical valve 3, and a mechanical valve Press block 4, rocker 5, cam link mechanism 6, seed box 7, chute 8, suction nozzle 9, seed pipe 10, shaft 11, spring 12, micro vacuum pump 13 and box body 14, mechanical valve 3, mechanical Valve briquetting block 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com