Micro tillage machine with double rotary tiller shaft and speed control lever

A technology of speed control and micro-tiller, which is applied in the field of micro-tiller, and can solve the problem that the machine can no longer continue to work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

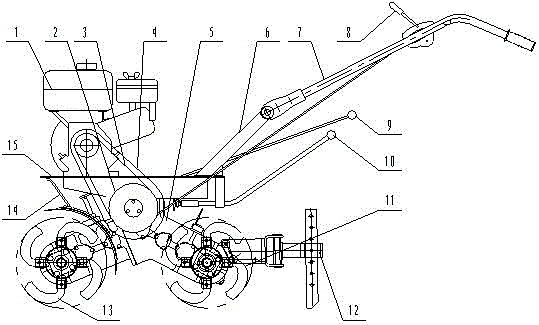

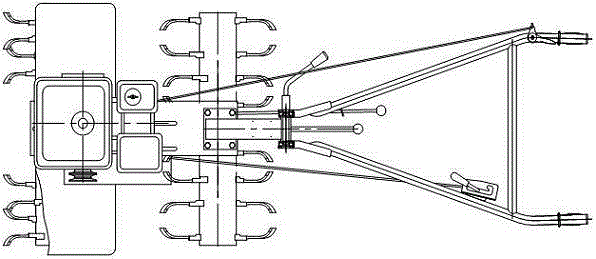

[0025] Embodiment 1, the complete machine structure of the present invention is as figure 1 figure 2 As shown, the power mechanism (1) is installed in front of the gearbox body assembly (5), the front rotary tiller (13) is installed in front of the gearbox body assembly (5), and the rear of the gearbox body (18) Armrest mounting seat (6) is installed, armrest frame (7) is installed above the armrest mounting seat (6), and rear rotary tiller (11) and speed control mechanism (12) are installed at the rear.

Embodiment 2

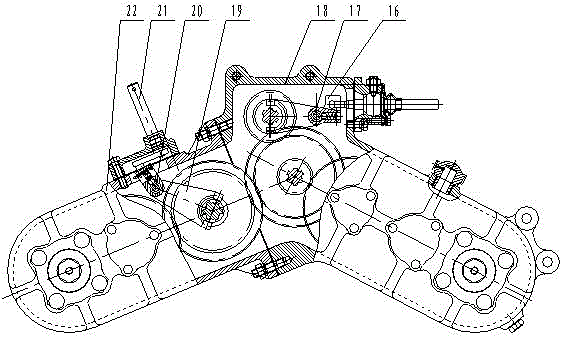

[0026] Embodiment 2, the power device (1) transmits the power to the pulley (2) through the V-belt (3), and the pulley (2) drives the I shaft (25) and the I-II gear (24) on the I shaft to rotate, The Ⅰ-Ⅱ gear (24) transmits power to the Ⅱ shaft Ⅰ gear (26) on the Ⅱ shaft (27), the Ⅱ shaft Ⅱ gear (29) and the Ⅱ shaft transmission gear (28), and then the Ⅱ shaft transmission gear (28) is transmitted to the Ⅲ-axis large gear (30) and the Ⅲ-axis pinion (31), and then transmitted to the Ⅳ-axis double gear (32) by the Ⅲ-axis pinion (31), and the Ⅳ-axis double gear (32) Sent to the rear rotary tiller gear (34) and rotary tiller shaft (35) to make the rear rotary tiller work.

[0027] The power transmission route of the front rotary tillage part is: the power is transmitted to the second gear (29) of the third shaft, and the second gear (29) of the second shaft is transmitted to the rotary tiller transmission gear on the separation drive shaft (38). (37), at this time, if the shiftin...

Embodiment 3

[0029]Embodiment 3, a micro tillage machine with double rotary tiller shafts and speed control levers, including a power mechanism, a pulley, a V-belt, a belt cover, a gearbox body assembly, an armrest mounting seat, an armrest frame, a clutch handle, and a rotary tiller clutch Handle, variable speed handle, rear rotary tiller assembly, speed control mechanism, front rotary tiller assembly, fender bracket, frame, variable speed fork, variable speed fork shaft, gearbox body, front rotary tiller Gear shift fork, front rotary tillage fork shaft, welding parts of clutch shift fork lever, front rotary tiller box, belt pulley, Ⅰ-Ⅱ gear, Ⅰ shaft, Ⅱ shaft Ⅰ gear, Ⅱ shaft, Ⅱ shaft transmission gear , Ⅱ shaft gear Ⅱ, Ⅲ shaft large gear, Ⅲ shaft pinion gear, Ⅳ shaft dual gear, Ⅳ shaft, rotary tillage gear, rotary tillage shaft, gear gear, rotary tillage transmission gear, separation drive shaft, Ⅲ shaft, It is characterized in that: 1) The gearbox body assembly (5) is a herringbone struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com