Control device for automatic transmission

A technology of automatic transmission and control device, applied in the direction of transmission device, fluid transmission device, transmission device control, etc., can solve the problems of violating the idling feeling, slow shifting, etc., and achieve the effect of suppressing the impact of shifting, avoiding sluggishness and idling feeling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

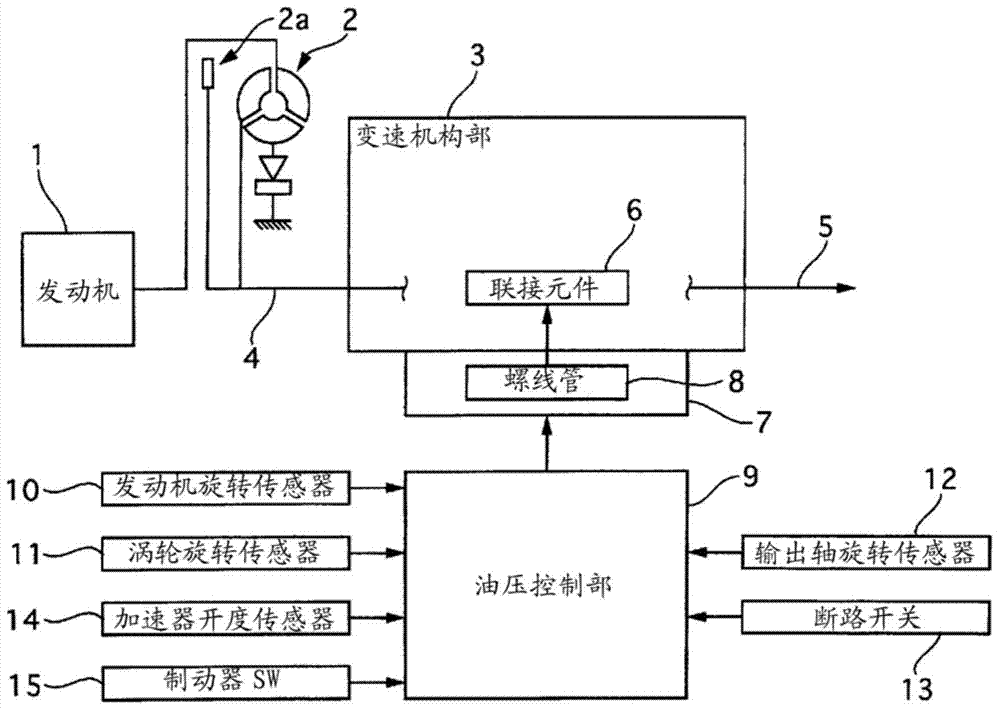

[0015] figure 1 It is a schematic diagram showing the system configuration of the automatic transmission of the first embodiment. An engine 1 is connected to a transmission mechanism unit 3 of an automatic transmission via a torque converter 2 . The engine 1 increases or decreases the output through the throttle valve whose opening increases from fully closed to fully open in conjunction with the accelerator pedal operated by the driver. The output rotation of the engine 1 passes through the torque converter 2 and is input to the transmission mechanism 3 input shaft 4. The torque converter 2 employs a well-known configuration having a function of amplifying the output torque of the engine 1 by generating a difference between input and output rotational speeds. In addition, the torque converter 2 is provided with a lock-up clutch 2a that can suppress the difference in input and output rotational speeds, in other words, can suppress the torque amplification effect, and can dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com