Blasting compositions

A composition and explosive technology, applied in explosives, non-explosive/non-thermic components, offensive equipment, etc., can solve problems such as blocking key equipment, damaging products, and depending on volume density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

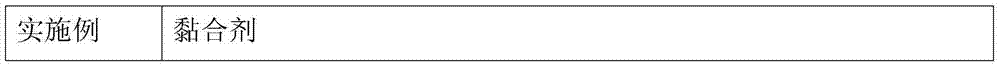

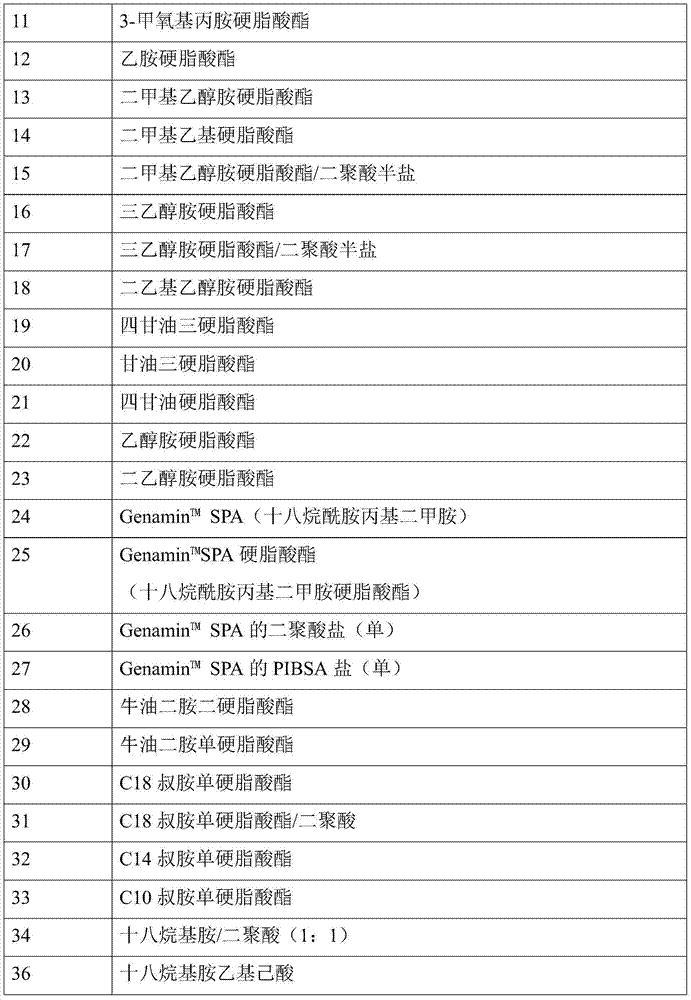

Examples

Embodiment 01- 2

[0046] Example 01 - dimer acid

[0047] A dimer acid (36 carbon units) was tested as a binder in an emulsion blasting composition. The stability of the emulsion remained good and had an overall improved water resistance when compared to the standard emulsion without added binder. About 10% to 30% of the fuel components are replaced with dimer acid. It dissolves easily in diesel. The explosive mixture allows 28 to 94% AN and 1.8 to 6% fuel oil. Both HDAN and LDAN grains can be used.

Embodiment 02

[0048] Example 02 - Oleayl dimer monostearate

[0049] Oleyl dimer stearate (C54) was tested. It has good emulsification stability and good water resistance. The binder replaces 10% to 30% of the fuel components, and it is easily soluble in diesel fuel, and is mixed with HDAN and LDAN pellets, 56-94% AN and 1.8-6% FO.

Embodiment 03

[0050] Example 03 - Oleyl Dimer Distearate

[0051] The oleyl dimer distearic acid (C72) was tested. It has good emulsification stability and good water resistance. The binder replaces 10% to 30% of the fuel components, and it is easily soluble in diesel fuel, and is mixed with HDAN and LDAN pellets, 56-94% AN and 1.8-6% FO.

[0052] Example 04 - Dimer Acid / Genamin OL500D

[0053] Dimer acid and Genamin tested TM A mixture of OL500D. Genamin OL500D is a distilled ammonium oleyl acetate compound. Has average emulsion stability with some slight crystallization. The binder replaces 20% to 50% of the fuel components, and it is easily soluble in diesel, and is mixed with HDAN and LDAN pellets, 56-94% AN and 1.8-6% FO.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com