Method and calibration model for manufacturing calibration model of pipeline grouting quality testing instrument

A detection instrument and grouting technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as affecting wave speed, and achieve the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

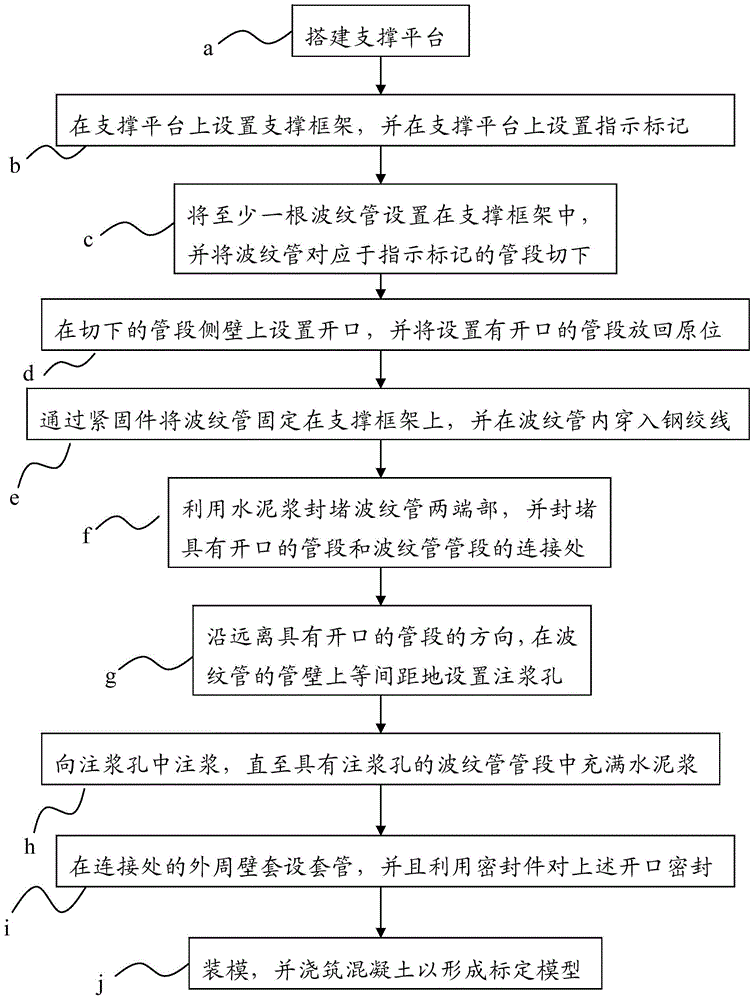

[0026] refer to figure 1 , an embodiment of the method for the calibration model of the manufacturing pipeline grouting quality detection instrument of the present invention, it comprises the steps:

[0027] Step a. Build a support platform. In this embodiment, a cuboid concrete support platform with a length of 20 m, a width of 0.5 m, and a height of 0.1 m is built. Preferably, the site is cleared prior to building the platform. The surface of the support platform with the largest area is in contact with the ground, and the direction of the height is the direction in which it protrudes from the ground.

[0028] Step b. Set the support frame on the support platform, and set the indicator mark on the support platform. In this embodiment, the supporting frame set on the supporting platform is a reinforced skeleton. After the reinforcement skeleton is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com