A piston polymer sampler for polymer injection wells

A piston type, polymer technology, applied in the direction of sampling devices, etc., can solve the problems of affecting the detection accuracy of polymer viscosity, difficult control of sampling operation, inaccurate polymer sampling, etc., to achieve compact structure, small footprint and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

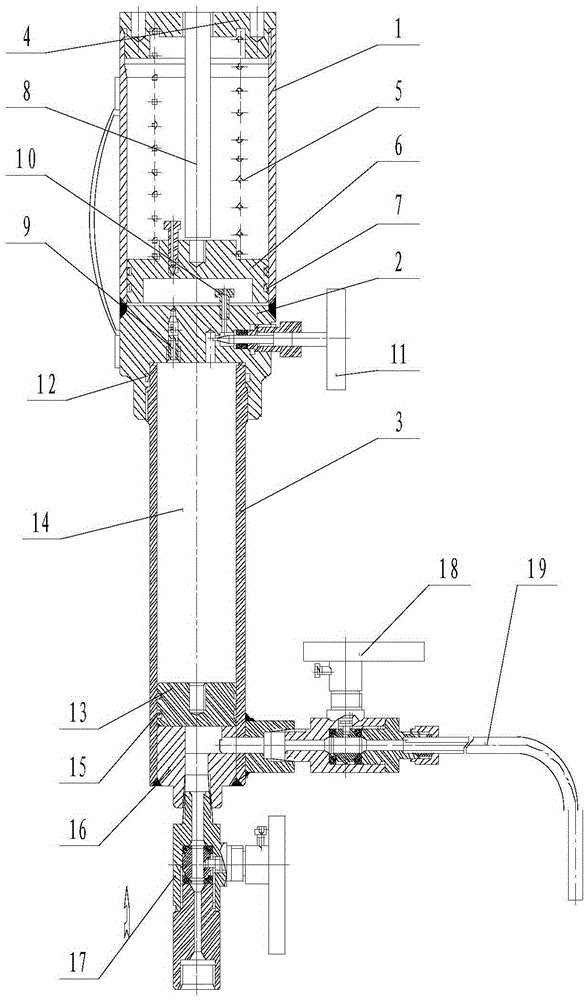

[0012] A piston-type polymer sampler for polymer injection wells, as shown in the accompanying drawings, includes a spring cylinder 1, a partition 2 and a sampling cylinder 3, the lower end of the spring cylinder 1 is welded and fixed to the upper end of the partition 2, and the spring The upper end of cylinder 1 is provided with top cover 4 and is threadedly connected with spring cylinder, and spring cylinder 4 is provided with spring 5 and spring cylinder piston 6, and the two ends of spring 5 join with top cover 4 and spring cylinder piston 6 respectively, and spring cylinder A piston ring a7 is arranged between the piston 6 and the spring cylinder 1, a circular hole is provided at the center of the top cover 4, a scale 8 is inserted in the circular hole, and the lower end of the scale 8 is threadedly connected and fixed with the upper surface center screw hole of the spring cylinder piston 6; There are vertical through-holes and double L-shaped through-holes inside the clap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com