Quick repair method for boiler lining material

A lining and boiler technology, which is applied in the field of boiler lining rapid repair, can solve the problems of shortening boiler maintenance time, long maintenance time, and affecting the economic benefits of boiler owners, so as to prolong the normal operation time, reduce maintenance costs, and improve customer satisfaction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

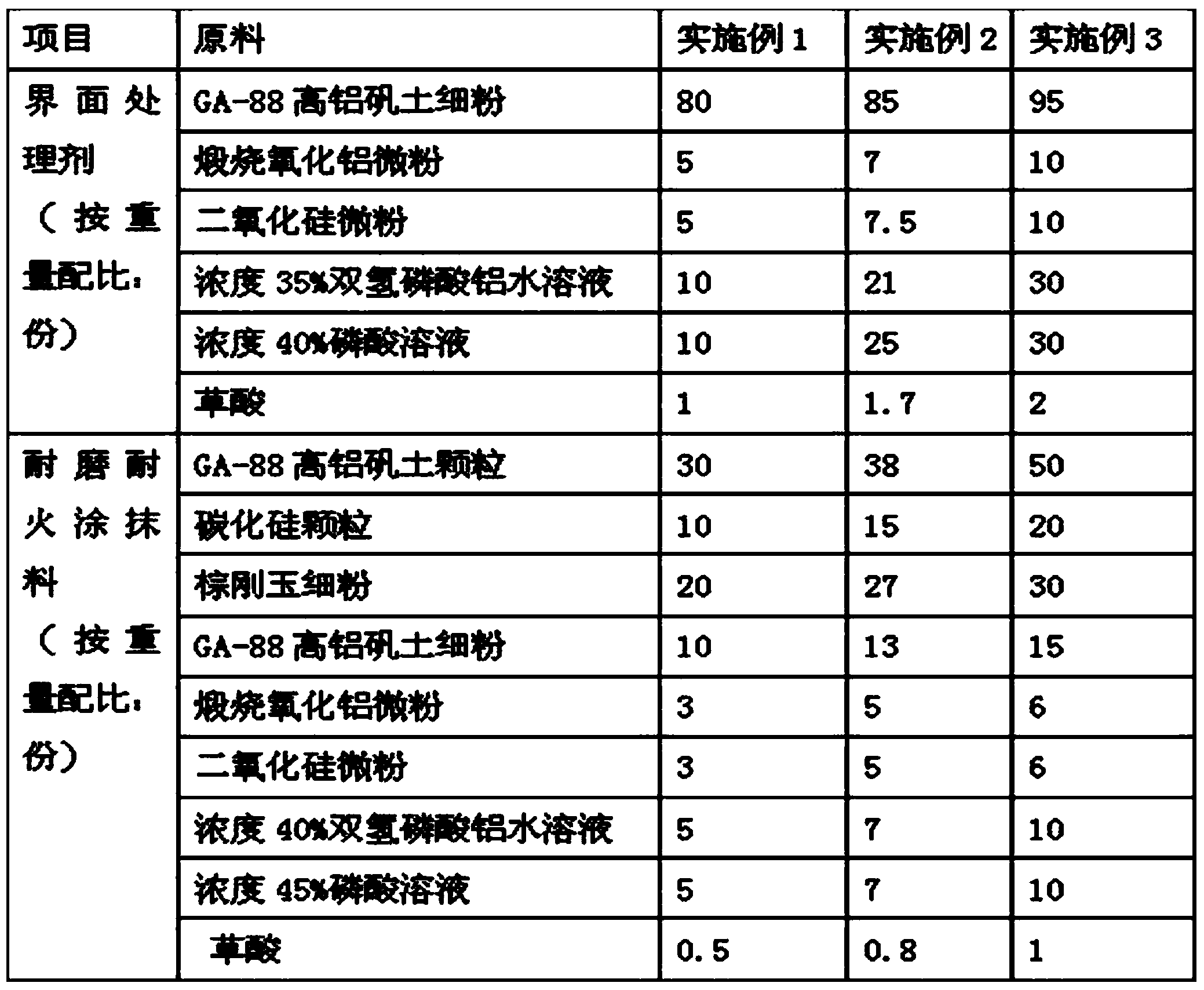

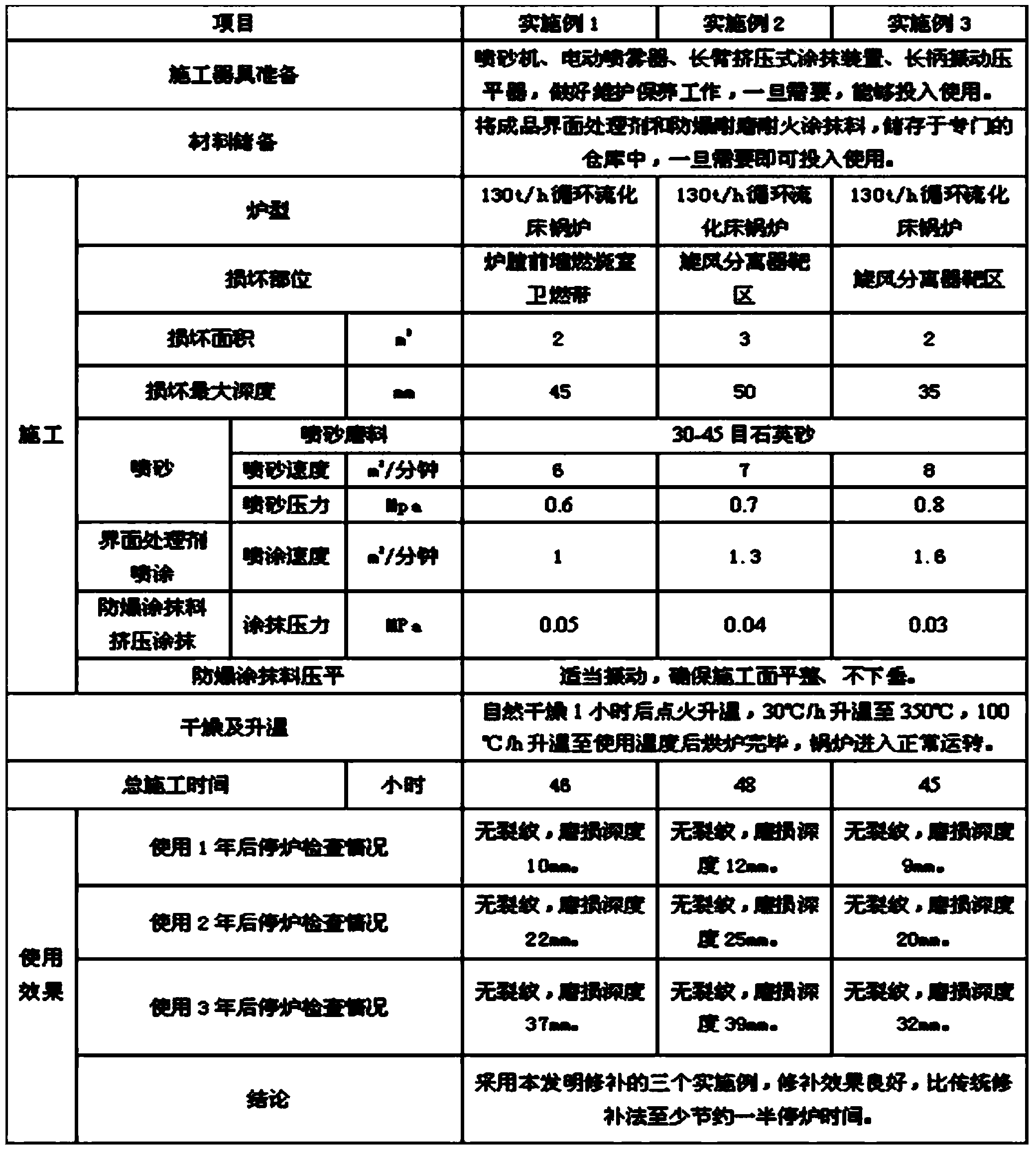

[0026] The present invention will be further described in detail below in conjunction with specific embodiments.

[0027] In the present invention, 4 kinds of construction tools are used: sandblasting machine, electric sprayer, long-arm extrusion type smearing device, long-handled vibration flattener; two materials are used: interface treatment agent and explosion-proof, wear-resistant and refractory smear ; A quick boiler lining repair method is provided, which replaces the traditional boiler lining repair method. The specific implementation steps are as follows:

[0028] (1) Preparation of construction equipment: sandblasting machine, electric sprayer, long-arm extrusion type coating device, long-handle vibrating flattener, Party B usually does maintenance work, and has a special warehouse for storage, and can be put into use immediately if needed;

[0029] (2) Preparation of interface treatment agent and wear-resistant and refractory smear: the prepared finished interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com