Supporting device for roof advance support in process of tunneling in caving loose rock mass and application of supporting device

A technology of advanced support and support device, which is applied to support the roof beam of the mine roof, mining equipment, earth square drilling and mining, etc. It can solve problems such as hidden safety hazards, ineffective support methods, support failures, etc., and achieve reliable support , Easy to operate, and the effect of easy operation for workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

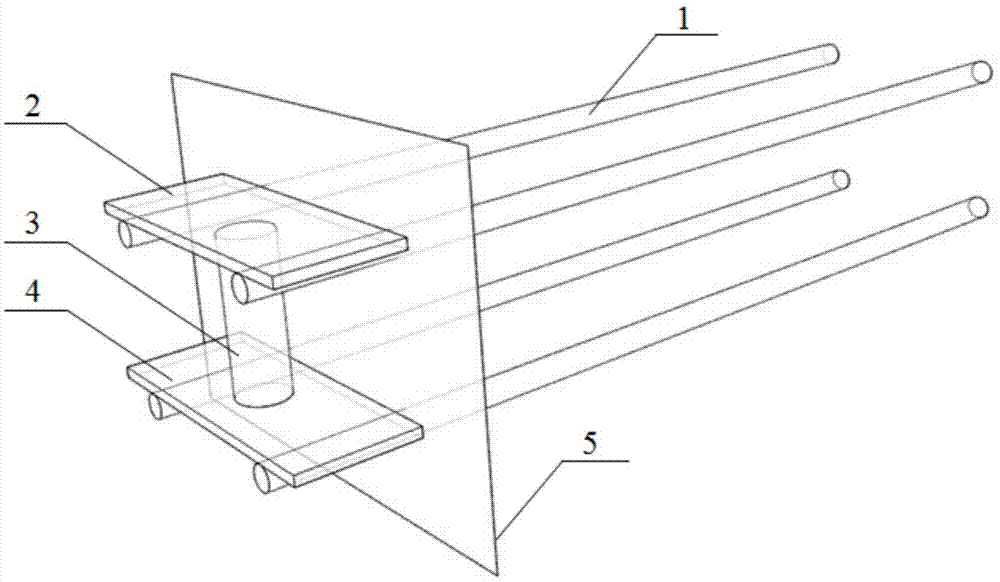

[0021] see figure 1 , four round steels 1 form a rectangular structure with two upper floors and two lower floors, an upper steel plate 2 is welded between the ends of the two upper round steels 1, and the ends of the two lower round steels A lower steel plate 4 is welded between them, and a steel pipe 3 is fixedly connected between the upper steel plate 2 and the lower steel plate 4 to enhance the vertical rigidity.

[0022] Preferably, steel pipes 3 are used to connect the upper steel plate 2 and the lower steel plate 4 by welding.

[0023] Preferably, the thickness of the upper steel plate 2 and the lower steel plate 4 is 20mm, and the length×width is 200mm×500mm.

[0024] Preferably, the specification of the steel pipe 3 is Φ80mm in diameter, 10mm in wall thickness, and 250mm in length.

[0025] Preferably, the round steel 1 has a diamet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com