A multi-stage height adjustment boltless fastener assembly

A bolt-free, height-adjusting technology, applied in roads, rails, buildings, etc., can solve problems such as bolt loosening safety, complicated installation, and hidden failures, and achieve the effects of ensuring uniform stability, convenient installation and adjustment, and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention is described in conjunction with accompanying drawing and specific embodiment:

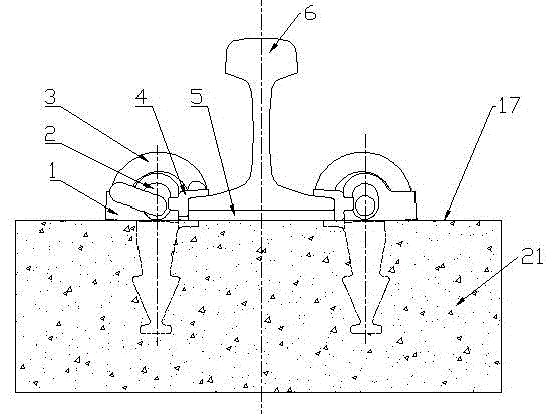

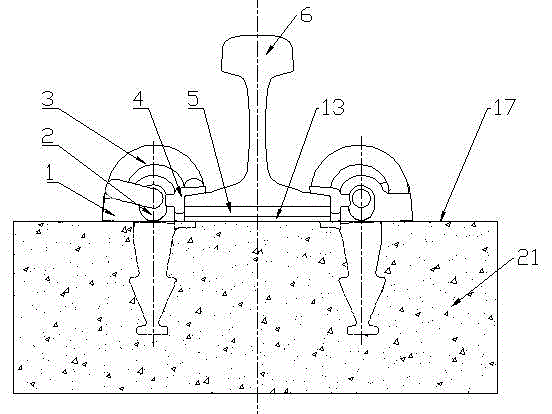

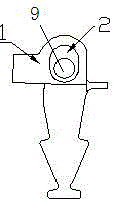

[0038] Such as figure 1 As shown, a multi-level height adjustment boltless fastener system, said multi-level height adjustment bolt-free fastener system includes a pre-embedded base 1, elastic strips 3, insulating gauge blocks 4 and under-rail elastic pads 5 The toe end of the elastic strip of the elastic strip 3 is installed on the embedded base 1, and the buckled toe end 11 of the elastic strip 3 is buckled on the rail 6 through the insulating gauge block 4; on the embedded base 1 An adjustment sleeve 2 is installed; the position of the adjustment sleeve 2 on the pre-embedded base 1 is an adjustable structure; the adjustment sleeve 2 has an eccentrically arranged elastic mounting hole 9, and the elastic middle toe of the elastic 3 The end is installed on the elastic strip installation hole 9 on the adjustment sleeve 2; on the pre-embedded base 1, by adjusting the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com