Simultaneous on-line zinc spraying and dust removal device for multiple micro-channel aluminum flat tubes

A technology of dust removal device and aluminum flat tube, which is applied in the direction of combined device, arc spraying, melt spraying, etc., to achieve the effects of reducing impact and damage, saving materials, and reducing compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

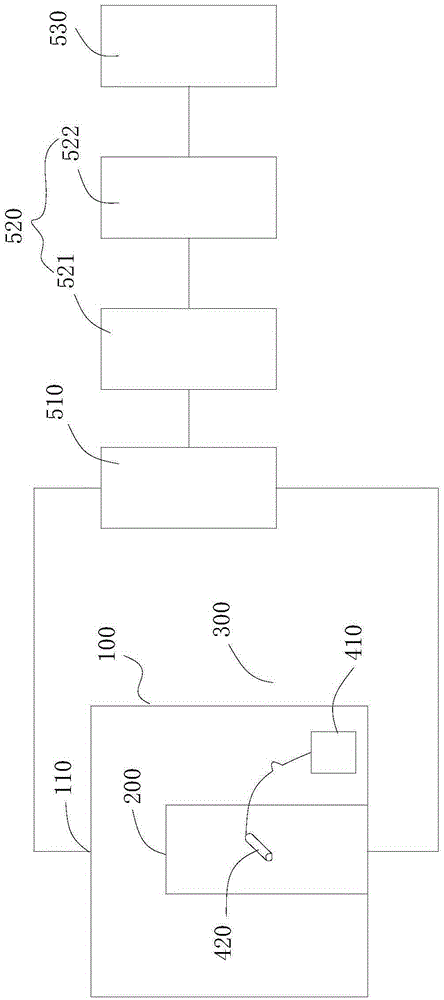

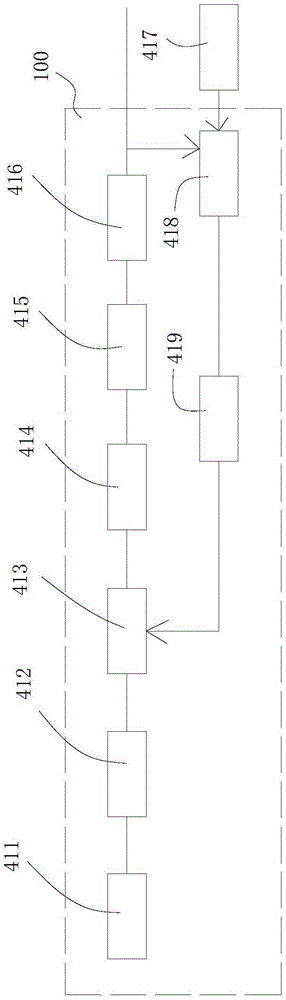

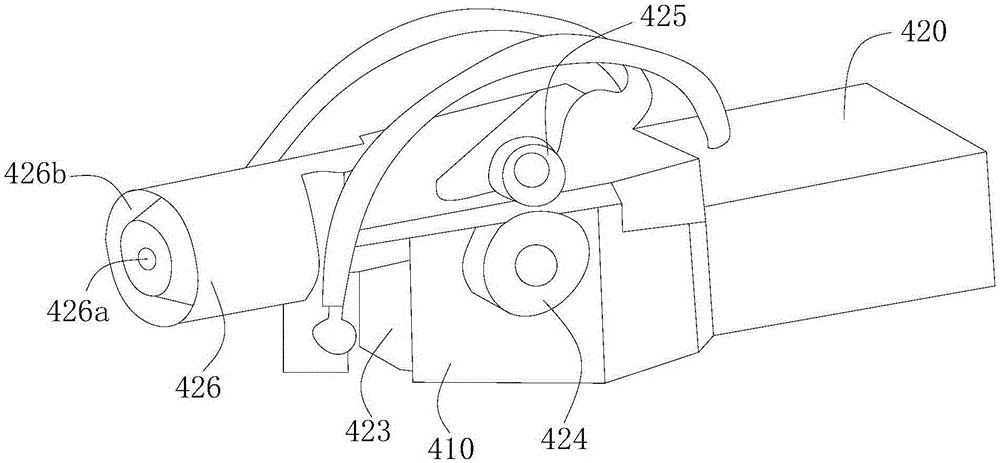

[0065] see figure 1 , multiple micro-channel aluminum flat tubes simultaneously on-line zinc spraying and dust removal device, including spraying equipment, spraying cabinet 100, light and noise isolation room 200 and dust removal device.

[0066] A plurality of micro-channel aluminum flat tubes 300 enter the spraying cabinet 100 from one side of the spraying cabinet 100 in parallel, and then exit the spraying cabinet 100 from the other side of the spraying cabinet 100; the light-noise isolation room is provided with 200 for multiple micro-channels The channel for the aluminum flat tube to enter and exit, through which a plurality of microchannel aluminum flat tubes 300 pass through the light-noise isolation room 200; a safety door is set on the light-noise isolation room 200; the wall of the light-noise isolation room 200 adopts a three-layer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com