A method of wearing and installing flexible furnace rolls of continuous annealing furnace

A continuous annealing furnace, annealing furnace technology, applied in the direction of furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of unsafety, low installation efficiency, high labor intensity, etc., and achieve the effect of eliminating damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

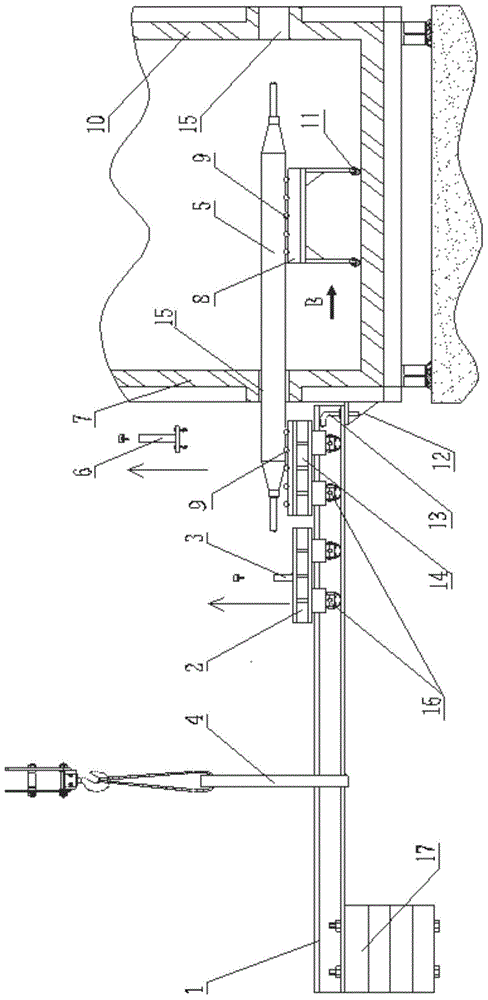

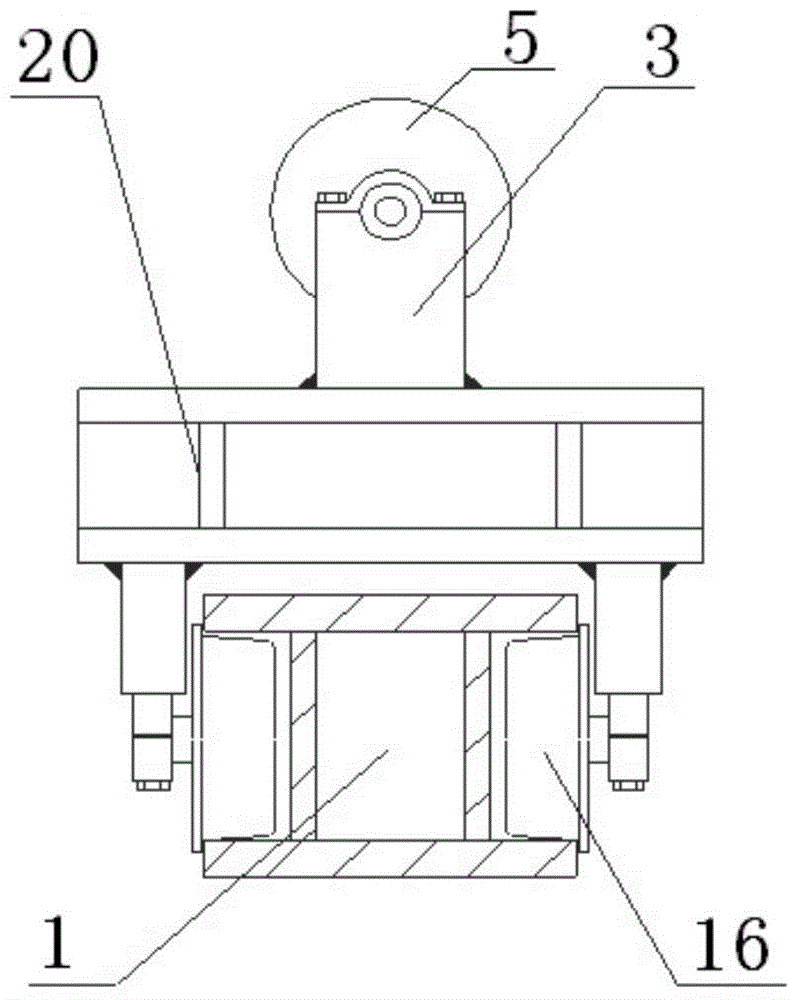

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0024] See figure 1 , figure 2 , is a schematic diagram of the process of wearing a flexible furnace roll in a continuous annealing furnace according to the present invention, mainly using a rolling trolley and a support and guide device to implement the wearing process of the flexible furnace roll, and the specific implementation steps are as follows:

[0025] 1. Preparation for hoisting of roller trolley

[0026] (1) Assemble the jig trailer 2 and the roller trailer 14 with the roller piercing trolley 1 respectively, and debug the safe and stable movement of the fixture trailer 2 and the roller trolley 14 on the roller piercing trolley; install the roller piercing trolley counterweight 17 at the roll piercing preparation position;

[0027] (2) Place the fixture trailer 2 on the left side of the hoisting point 4 of the lifting frame of the rol...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap