A combustion-supporting anti-coking agent for an oil-fired boiler and its addition method

An anti-coking agent and oil-fired boiler technology, applied in the direction of fuel additives, fuel, petroleum industry, etc., can solve the problems of high price of high-quality fuel oil, high cost pressure, insignificant anti-coking effect and smoke elimination effect, etc., to achieve guaranteed Long-term high-efficiency operation, energy saving, and the effect of reducing furnace coking and spray gun clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

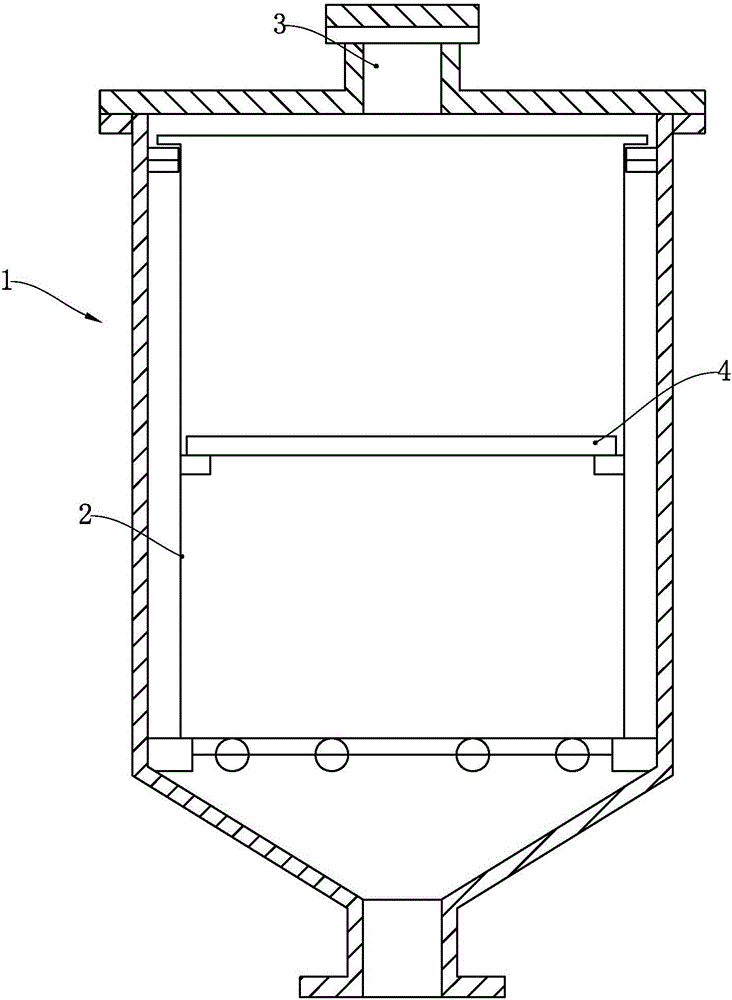

Image

Examples

Embodiment 1

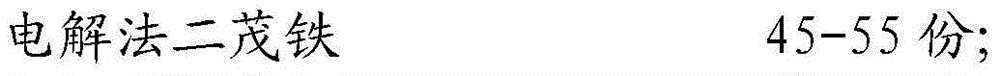

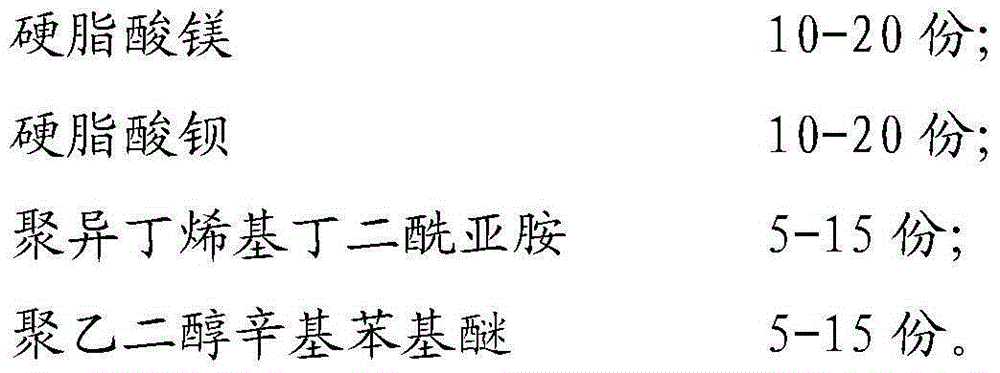

[0039] A combustion-supporting anti-coking agent for an oil-fired boiler, which is prepared from the following raw materials in parts by weight:

[0040]

Embodiment 2

[0042] A combustion-supporting anti-coking agent for an oil-fired boiler, which is prepared from the following raw materials in parts by weight:

[0043]

Embodiment 3

[0045] A combustion-supporting anti-coking agent for an oil-fired boiler, which is prepared from the following raw materials in parts by weight:

[0046]

[0047]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com