Advanced treatment process and system for cassava-based ethanol wastewater

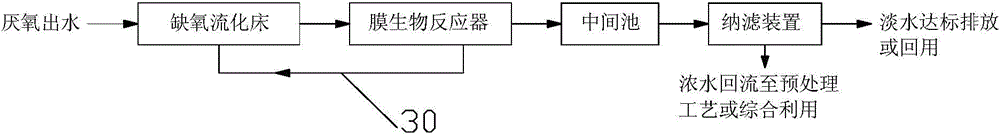

A technology for advanced treatment and wastewater treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, permeation/dialysis water/sewage treatment, etc. and other problems, to achieve the effect of reducing total nitrogen discharge, improving treatment effect and treating water quality well.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

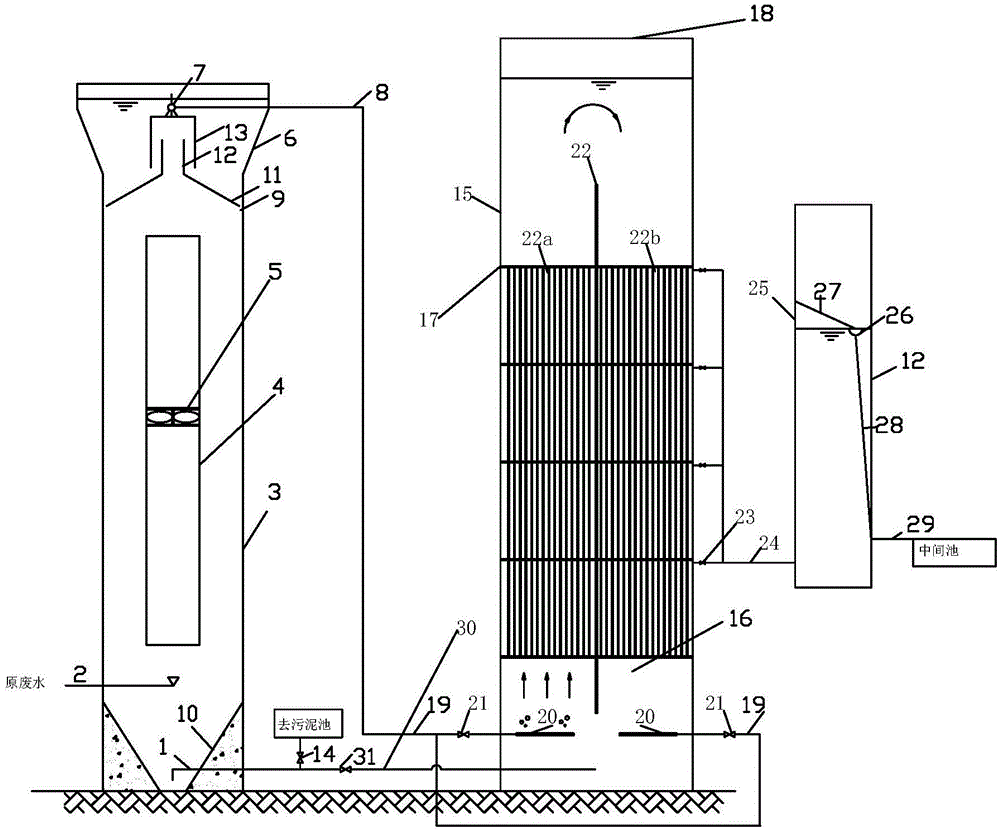

Method used

Image

Examples

Embodiment

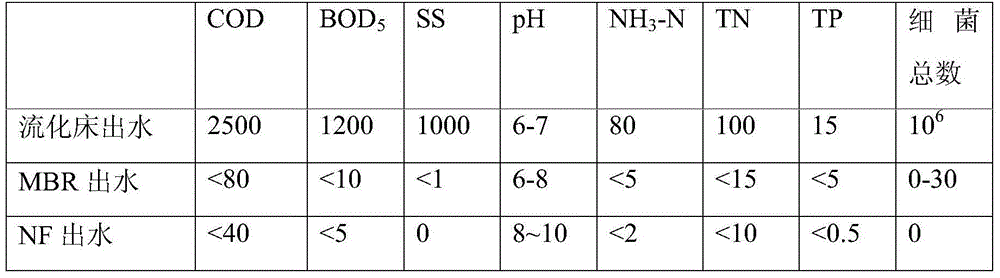

[0039] A cassava ethanol production wastewater, the total treated water volume is 5000m3 / d, the pollutant concentration in the influent is: COD=48000mg / L, SS=30000mg / L, after anaerobic treatment, it reaches COD=2500mg / L, SS=1000mg / L index of. After anoxic fluidized bed, MBR and nanofiltration advanced treatment. Among them, the MBR controls the residence time of 30h, the reflux ratio is 500%, and the pH of the effluent is controlled at 9.5 to enter the nanofiltration. The water quality after treatment is shown in the table below:

[0040]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com