Aeration system of MBR (Membrane Bio-Reactor) membrane module and control method of aeration system

An aeration system and membrane module technology, applied in chemical instruments and methods, sustainable biological treatment, water/sludge/sewage treatment, etc., can solve the problems of high aeration energy consumption, short life of MBR membrane modules, and easy fouling of membranes Pollution and other issues, to achieve the effect of small aeration, saving equipment investment, and reducing fan selection

Active Publication Date: 2014-07-23

POWERCHINA ZHONGNAN ENG +1

View PDF4 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] In order to overcome the disadvantages of the existing MBR membrane module aeration system, which are easy to pollute the membrane, or the aeration energy consumption is high, or the life of the MBR memb

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

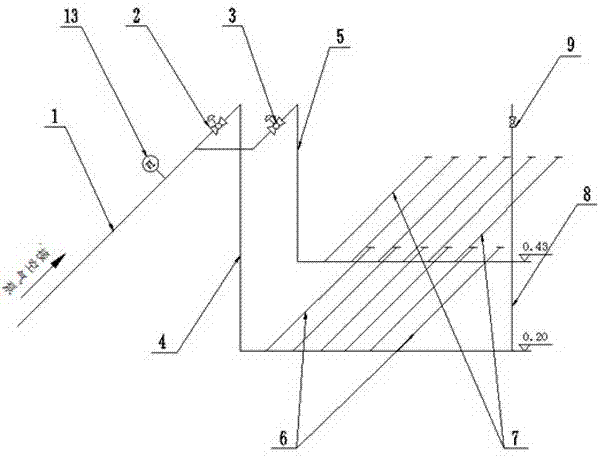

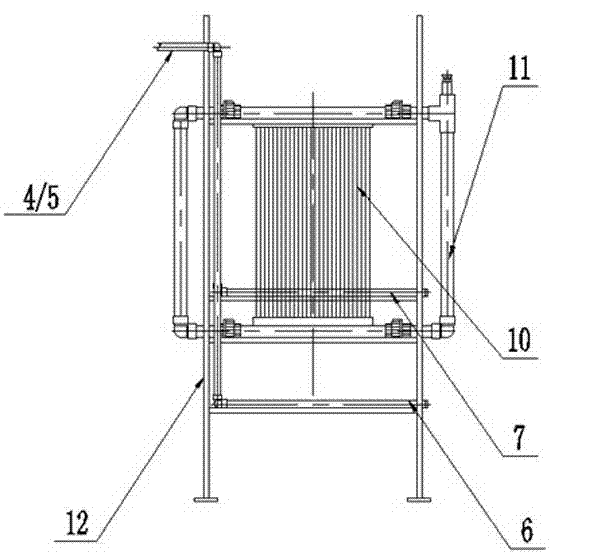

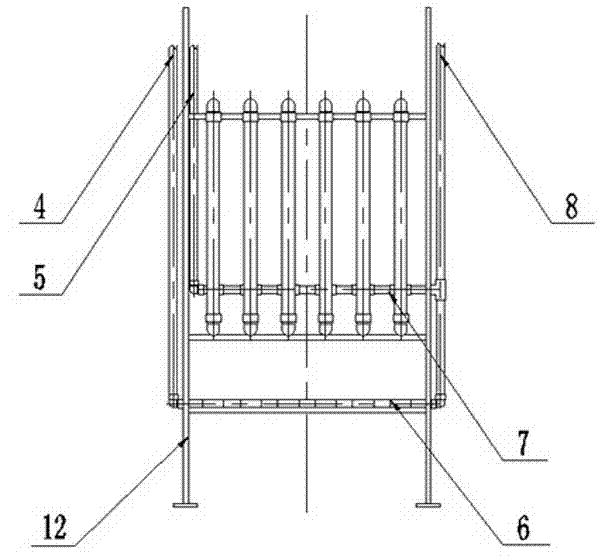

The invention discloses an aeration system of an MBR (Membrane Bio-Reactor) membrane module and a control method of the aeration system, and aims to solve the problem of easily-caused environment pollution or high aeration energy consumption or short service life of the MBR membrane module in the traditional aeration system of the MBR membrane module. The aeration system of the MBR membrane module comprises an MBR aeration manifold, an upper-layer aeration manifold, a lower-layer aeration manifold, a plurality of upper-layer aeration branch pipes and a plurality of lower-layer aeration branch pipes, wherein the MBR aeration manifold is arranged in an MBR tank; the upper-layer aeration manifold and the lower-layer aeration manifold are communicated with the MBR aeration manifold; the plurality of upper-layer aeration branch pipes are communicated with the upper-layer aeration manifold; the plurality of lower-layer aeration branch pipes are communicated with the lower-layer aeration manifold; the plurality of upper-layer aeration branch pipes are located on the same horizontal plane which is 400-450mm far away from the bottom of the MBR tank; the plurality of lower-layer aeration branch pipes are located on the same horizontal plane which is 150-250mm far away from the bottom of the MBR tank. The aeration system disclosed by the invention can be used for effectively controlling membrane pollution by using relatively low air flow.

Description

technical field [0001] The invention relates to an MBR membrane module aeration system and a control method. Background technique [0002] MBR membrane bioreactor is a new method of sewage treatment that combines activated sludge method and membrane separation technology, and replaces the secondary sedimentation tank in traditional conventional activated sludge method with membrane separation technology. Compared with the traditional activated sludge method, it has many advantages such as good and stable effluent quality, less residual sludge output, small footprint, easy installation, and convenient operation. At the same time, there are also some problems in the actual application process, such as easy pollution, high energy consumption, and relatively short service life. [0003] There are many methods to control membrane fouling, among which the most important method is to use continuous aeration to scour the membrane surface. In order to achieve the effect of controll...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C02F3/00C02F3/12

CPCY02W10/10

Inventor 徐巍李勇陈湘斌禹芝文黎慧娟

Owner POWERCHINA ZHONGNAN ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com